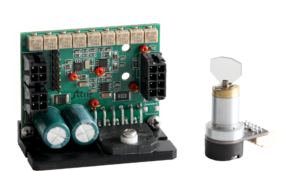

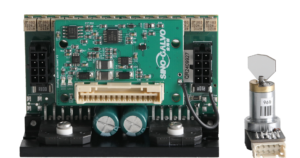

Sino-Galvo 1105 Galvo Motor with High Speed Mini Size

- Control board, motor performance and mirrors can be customized to your needs

- Warranty for 18 months

What are the advantages of our motors?

- Control board can be customized, for example, board dimension, single axis or dual axis, Pin

- Motor performance parameters can be tested according to your needs

- The mirrors wavelength is optional

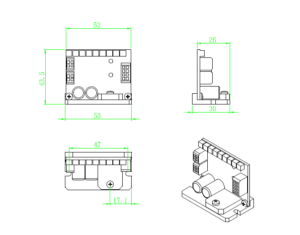

Single axis drive board dimension drawing

| 1105 Galvo Motor Specification | |

| Working Temperature | 0℃-45℃ |

| Linearity | 99.9% |

| Small Step Response Time | ≤0.35ms |

| Scale Drift | <40PPM/℃ |

| Zero Drift | <15μRad./℃ |

| Long-term Drift over 8 Hours | <0.5mRad. |

| Rated Current | 2.0A |

| Scan Angle | ±11° |

| Repeatability | 8μRad. |

| Aperture | 5mm-7mm |

| Weight | 13.0g |

| Servo Driver board specifications | |

| Input Voltage | ±15VDC |

| Analog signal input range (Max) | ±5V |

| Fault signal output (CMOS level) | H for Normal; L for Faulty |

| Analog signal input resistance | 10KΩ±1% |

| Working Temperature | 25℃±10℃ |

What is a galvo motor?

A galvo motor is a type of rotary motor used to control the movement of mirrors in laser systems, allowing for fast and precise beam steering. It’s commonly used in applications like laser scanning, engraving, marking, and cutting.

How does a galvo motor work?

Galvo motors use electromagnetic principles to rotate a mirror attached to the motor shaft. When current flows through the motor’s coils, it generates a magnetic field that moves the rotor to adjust the mirror’s angle. Feedback sensors monitor the position to ensure accuracy and speed.

What are the key benefits of using galvo motors in laser systems?

- High precision and speed

- Low latency in beam steering

- Compact size for integration in various laser applications

- Ability to handle complex patterns with high accuracy

What factors should I consider when choosing a galvo motor?

- Speed: How fast the motor can move the mirror.

- Accuracy: The precision of the motor’s positioning.

- Mirror size: The size of the mirror attached to the motor for laser beam manipulation.

- Laser power: Compatibility with the power of your laser system.

- Operating environment: Ensure the motor can function in your temperature and humidity conditions.

What is the lifespan of a galvo motor?

The lifespan of a galvo motor depends on usage and operating conditions. With proper maintenance, many galvo motors can last several years in continuous operation. Regular maintenance and calibration can extend its life.

How do I maintain a galvo motor?

- Regular calibration to ensure precision

- Keeping the operating environment clean to avoid dust or particles damaging the motor

- Checking for wear and tear on the mirrors and motor components

- Ensuring proper cooling and ventilation to prevent overheating

What are the differences between galvo motors and stepper motors?

- Precision: Galvo motors offer higher precision and faster response times than stepper motors.

- Speed: Galvo motors are designed for high-speed applications, while stepper motors are better for lower-speed tasks.

- Applications: Galvo motors are ideal for laser scanning and fast beam steering, while stepper motors are commonly used in slower, lower-precision systems.

What kind of feedback systems do galvo motors use?

Galvo motors typically use position feedback systems like optical encoders to monitor the position of the mirror in real-time. This ensures that the motor reaches and maintains the desired angle with high accuracy.

Can I replace the mirrors on a galvo motor?

Yes, mirrors can often be replaced, but it’s important to use compatible mirrors that match the specifications of the galvo motor and the laser system, such as size, coating, and reflectivity.