Laser Marking

HOW DOES LASER MARKING WORK

Laser marking is to use the high energy density of the laser beam to vaporize the surface of the workpiece, or cause chemical reactions to form traces to achieve the purpose of processing. The general laser marking system consists of a laser, a power supply, a light guide system, a cooling system, control system and workbench.

The ADVANTAGES OF LASER MARKING

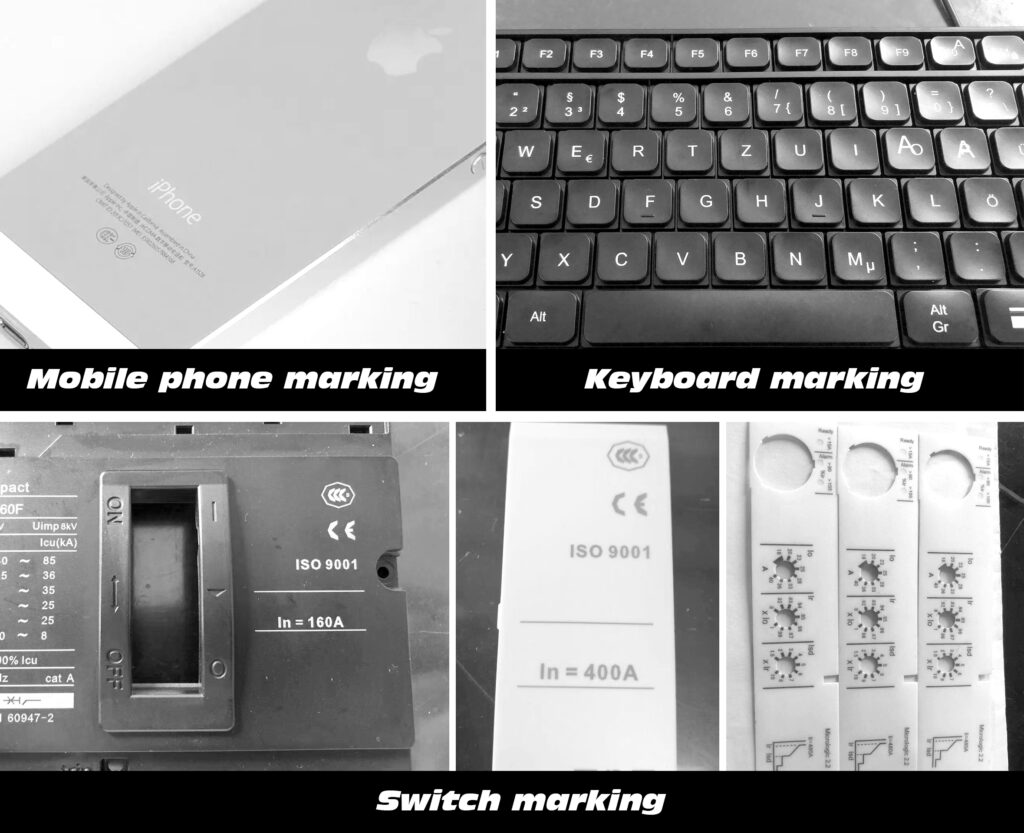

Compared with traditional methods such as chemical corrosion, mechanical stamping, and electric fire writing, laser marking technology has no loss, no disturbance, no deformation to the workpiece, and no pollution to the environment. As shown in the figure below, the common inkjet marking needs to consume a certain amount of toner during the marking process (the cost is high), and the plastic, glass and leather marks are easy to fall off and modify in a certain environment, so the anti-counterfeiting effect is not good. Nowadays laser marking is widely used in automated production lines.

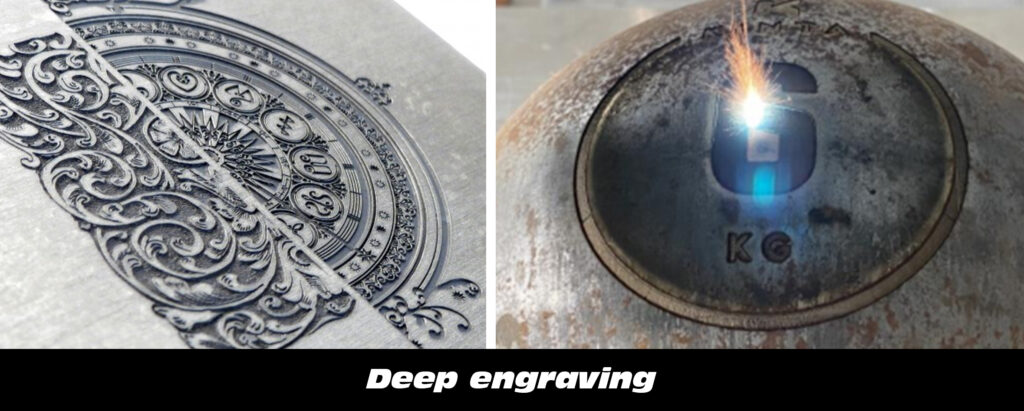

CLASSIFICATION OF LASER MARKING

Laser marking can be divided into: fiber laser 1064nm, suitable for most metal materials; CO2 laser 10.6μm, suitable for most non-metal materials, paper, leather, wood, plastic, plexiglass , fabric, acrylic, wood, bamboo, rubber, etc.; UV laser 355nm, is mainly used for ultra-fine marking and engraving, especially for food and pharmaceutical packaging marking, micro drilling, and complex graphic cutting of silicon wafers, etc.

APPLICATION OF LASER MARKING MACHINES

MOPA Fiber Laser Marking Machine

Aluminum blackening usually requires MOPA fiber laser marking machine with adjustable pulse width. Ordinary laser marking machine can only mark text information in gray or black gray on aluminum products, while MOPA can make magnesium aluminum, aluminum oxide, various Aluminum with a black finish. The principle of blackening of anodized aluminum is to further oxidize anodized aluminum with a film thickness of 5-20μm and change the surface material in a very short period by focusing a laser with high energy density. It is based on the nano-effect. After laser treatment, the size of oxide particles is nano-scale, so that the light absorption performance of the material is increased, so that visible light is absorbed by the material when it is irradiated, and the reflected visible light is very small, so it is black when observed by the naked eye.

The color marking on stainless steel is to use a high-energy density laser heat source to act on the stainless steel, to generate colored oxides on the surface, or to generate a colorless transparent oxide film. This is because of the light interference effect. Moreover, by controlling the laser energy and parameters, different colors of oxide layers with different thicknesses can be realized, and even color gradient marking can be realized.

Flying Marking

Online flying laser marking is a combination of fiber laser marking machine and assembly line, marking while feeding, which can automatically generate batch number and serial number, which greatly improves work efficiency. It is currently mainly used in the marking of outer packaging production lines, such as outer packaging such as food/skin care, molded and extruded products such as wires/cables, tubes, and pipes.

Portable Fiber Laser Marking Machine

Portable fiber laser marking machine is easy to carry, compact, does not take up space, good flexibility, environmental protection, and energy saving, can be hand-held for operation, and can laser mark large mechanical parts in any direction. It is suitable for customers who do not have high requirements for marking, and can meet basic needs.

CCD Vision Positioning Laser Marking Machine

CCD visual positioning laser marking machine uses the principle of visual positioning, mainly for the problems of difficult feeding, poor positioning and slow speed caused by the difficulty of fixture design and manufacture in batch irregular marking. Within the processing range, accurate marking can be achieved; even if the position is different each time, there is no problem with the processing position. It is suitable for heavy workload, difficult product positioning, diversity, and complexity of workpieces such as capacitors, IC cards, small screws, jewelry, etc.

3D Laser Marking Machine

The traditional 2D laser marking machine adopts the back focus method, which is only suitable for plane marking within the specified range, and the marking width is also limited. The 3D laser marking machine adopts advanced digital three-axis dynamic focusing technology, can realize three-dimensional curved surface laser marking. It is suitable for curved surface, stepped and large format marking.

Laser Marking

HOW DOES LASER MARKING WORK

Laser marking is to use the high energy density of the laser beam to vaporize the surface of the workpiece, or cause chemical reactions to form traces to achieve the purpose of processing. The general laser marking system consists of a laser, a power supply, a light guide system, a cooling system, control system and workbench.

The ADVANTAGES OF LASER MARKING

Compared with traditional methods such as chemical corrosion, mechanical stamping, and electric fire writing, laser marking technology has no loss, no disturbance, no deformation to the workpiece, and no pollution to the environment. As shown in the figure below, the common inkjet marking needs to consume a certain amount of toner during the marking process (the cost is high), and the plastic, glass and leather marks are easy to fall off and modify in a certain environment, so the anti-counterfeiting effect is not good. Nowadays laser marking is widely used in automated production lines.

CLASSIFICATION OF LASER MARKING

Laser marking can be divided into: fiber laser 1064nm, suitable for most metal materials; CO2 laser 10.6μm, suitable for most non-metal materials, paper, leather, wood, plastic, plexiglass , fabric, acrylic, wood, bamboo, rubber, etc.; UV laser 355nm, is mainly used for ultra-fine marking and engraving, especially for food and pharmaceutical packaging marking, micro drilling, and complex graphic cutting of silicon wafers, etc.

APPLICATION OF LASER MARKING MACHINES

MOPA Fiber Laser Marking Machine

Aluminum blackening usually requires MOPA fiber laser marking machine with adjustable pulse width. Ordinary laser marking machine can only mark text information in gray or black gray on aluminum products, while MOPA can make magnesium aluminum, aluminum oxide, various Aluminum with a black finish. The principle of blackening of anodized aluminum is to further oxidize anodized aluminum with a film thickness of 5-20μm and change the surface material in a very short period by focusing a laser with high energy density. It is based on the nano-effect. After laser treatment, the size of oxide particles is nano-scale, so that the light absorption performance of the material is increased, so that visible light is absorbed by the material when it is irradiated, and the reflected visible light is very small, so it is black when observed by the naked eye.

The color marking on stainless steel is to use a high-energy density laser heat source to act on the stainless steel, to generate colored oxides on the surface, or to generate a colorless transparent oxide film. This is because of the light interference effect. Moreover, by controlling the laser energy and parameters, different colors of oxide layers with different thicknesses can be realized, and even color gradient marking can be realized.

Flying Marking

Online flying laser marking is a combination of fiber laser marking machine and assembly line, marking while feeding, which can automatically generate batch number and serial number, which greatly improves work efficiency. It is currently mainly used in the marking of outer packaging production lines, such as outer packaging such as food/skin care, molded and extruded products such as wires/cables, tubes, and pipes.

Portable Fiber Laser Marking Machine

Portable fiber laser marking machine is easy to carry, compact, does not take up space, good flexibility, environmental protection, and energy saving, can be hand-held for operation, and can laser mark large mechanical parts in any direction. It is suitable for customers who do not have high requirements for marking, and can meet basic needs.

CCD Vision Positioning Laser Marking Machine

CCD visual positioning laser marking machine uses the principle of visual positioning, mainly for the problems of difficult feeding, poor positioning and slow speed caused by the difficulty of fixture design and manufacture in batch irregular marking. Within the processing range, accurate marking can be achieved; even if the position is different each time, there is no problem with the processing position. It is suitable for heavy workload, difficult product positioning, diversity, and complexity of workpieces such as capacitors, IC cards, small screws, jewelry, etc.

3D Laser Marking Machine

The traditional 2D laser marking machine adopts the back focus method, which is only suitable for plane marking within the specified range, and the marking width is also limited. The 3D laser marking machine adopts advanced digital three-axis dynamic focusing technology, can realize three-dimensional curved surface laser marking. It is suitable for curved surface, stepped and large format marking.