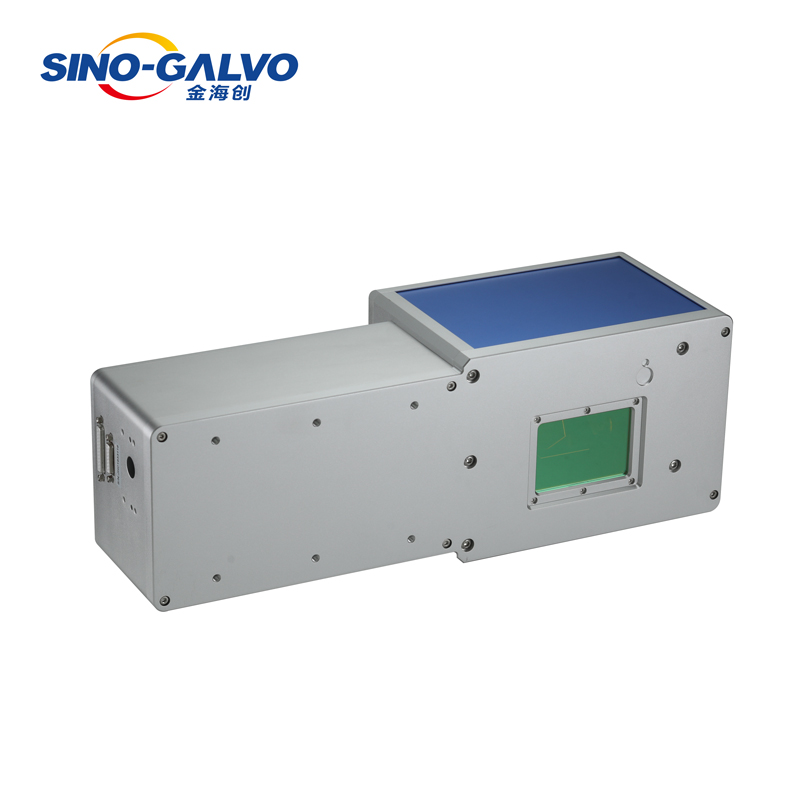

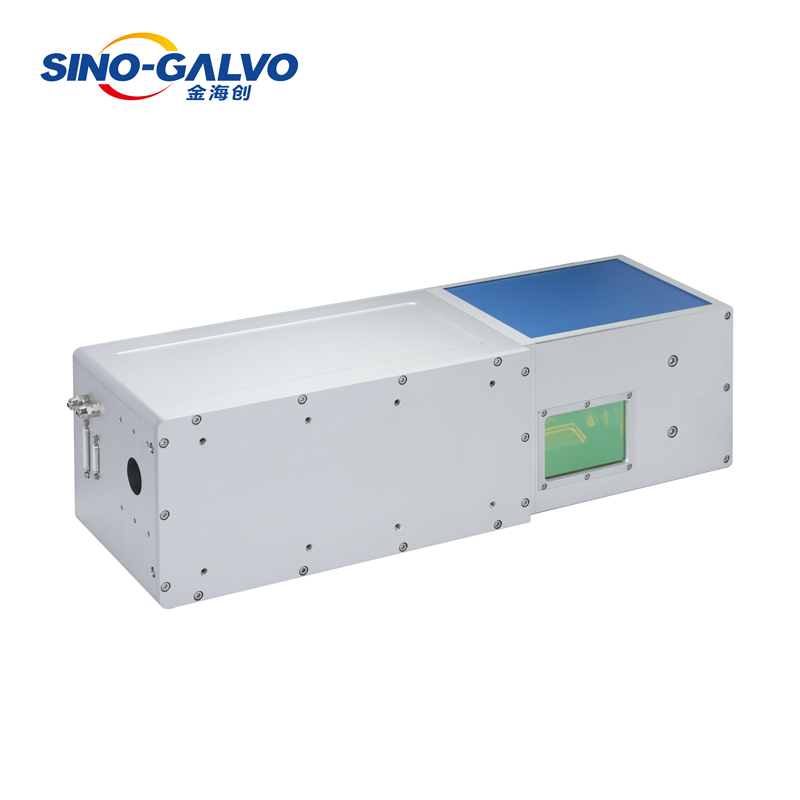

RF8330-3D 3D laser galvo scanner for RF CO2 laser

This 3D dynamic focus scanning system supports various laser processing, including large-format, complex curved surfaces, and 3D deep engraving.

RF8330-3D 3D laser galvo scanner for RF CO2 laser

This 3D dynamic focus scanning system supports various laser processing, including large-format, complex curved surfaces, and 3D deep engraving.

Product Features

Technical Parameters

Application Shows

Product Features

Features of 3D laser galvo scanner

RF8330-3D-1200 dynamic focusing system could achieve high precision line, no deformation, uniform power, and patterns.

- The maximum size of marking is 1200×1200mm, and any size from 300×300mm to 1200×1200mm can be customized

- Less optical loss, high positioning accuracy, fast marking speed, strong anti-interference ability and etc.

- The built-in MM3D software system supports multiple file formats and vector diagrams, bitmaps, and text barcodes, easy to operate

- Accurate load design for 30mm specular lenses, high motor assembly accuracy, reasonable structure, static friction coefficient, and zero-bit offset, to ensure the best dynamic characteristics of the system.

- The drive has the position and speeds prime detection function, which greatly enhances the dynamic response performance and scanning speed of the entire system.

- Adopts electromagnetic compatible optimization design, high signal-to-noise ratio, and strong anti-interference ability.

Technical Parameters

| Laser Type | 10600nm RF CO2 laser source |

| Printing Field | 300×300mm~1200×1200mm |

| Input Beam Size | 2.5~3mm |

| X&Y Axes Mirrors Aperture Size | 30mm |

| Precision and Error | |

| Linearity | 99.90% |

| Repeatability (RMS) | <8μRad |

| Gain Error | <5mRad |

| Zero Offset | <5mRad |

| Long-term Drift Over 8 Hours | <0.5mRad |

| Scale Drift | <40PPM/℃ |

| Zero Drift | <15μRad/℃ |

| Water-Cooling System | |

| Water Temperature | 25±3℃ |

| Maximum Water Pressure | <3bar |

| Water Flow | >1L/min |

| Water Pipe Specification | Outer diameter φ6mm Inner diameter φ4mm |

| Power and Signal | |

| Input Voltage | ±24VDC |

| Rated Current | 4A |

| Interface Signal | Digital: XY2-100 |

| Machinery Scan Angle | ±12.5° |

| Working Current, Temperature, Dimension | |

| Working Temperature | 0℃~45℃ |

| Storage Temperature | -10℃~60℃ |

| Galvanometer Scanner Dimension | 556.5×158×188mm (L×W×H) |

| Galvanometer Scanner Weight | ≈16.7Kg |

| Examples of Field Size,Working Distance, Spot Size and Depth Configurations | ||||||||||

| Field Size (mm) | 300×300 | 400×400 | 500×500 | 600×600 | 700×700 | 800×800 | 900×900 | 1000×1000 | 1100×1100 | 1200×1200 |

| Working Distance | 438mm | 500mm | 550mm | 645mm | 800mm | 1000mm | 1200mm | 1400mm | 1500mm | 1600mm |

| Spot Size | 239μm | 314μm | 389μm | 464μm | 539μm | 614μm | 689μm | 764μm | 839μm | 914μm |

| Depth | -30~0 | -40~0 | -50~0 | -60~0 | -70~0 | -80~0 | -80~0 | -80~0 | -80~0 | -80~0 |

Application Shows