What Is Metal 3D Printing

Metal 3D printing (also called metal additive manufacturing) uses a high-energy laser or electron beam to selectively melt metal powder layer by layer, forming complex 3D parts directly from CAD data.

Unlike subtractive methods, it needs no molds, supports rapid prototyping, and allows intricate lattice structures, internal channels, and lightweight designs impossible with traditional machining.

These advantages make metal 3D printing ideal for aerospace turbine blades, rocket nozzles, medical implants, mold tooling with conformal cooling, and high-end consumer products such as smartphone frames and smartwatch cases.

The Role of 3D Printing Optics

The performance of any metal 3D printer depends largely on its 3D printing optics—the optical system that guides, shapes, and focuses laser energy onto the powder bed.

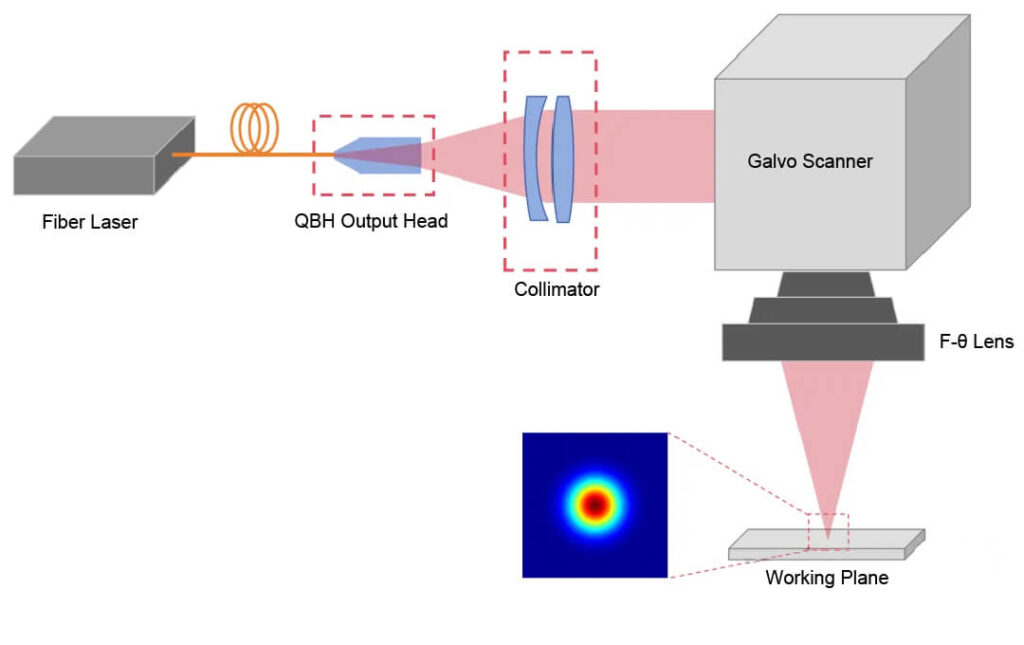

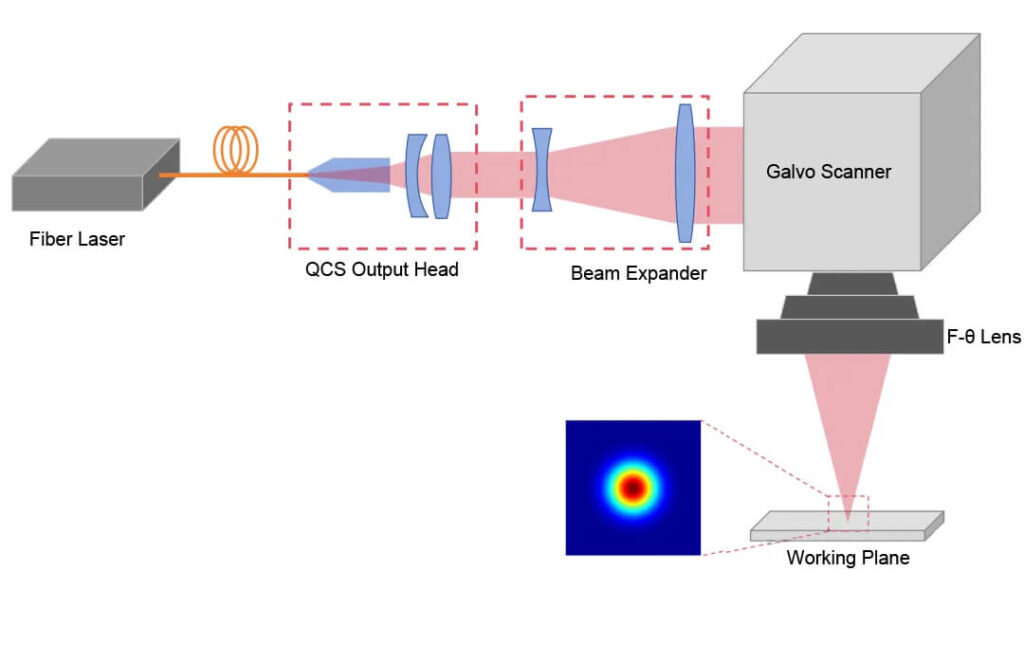

A well-designed optical path ensures consistent energy delivery, uniform melting, and precise feature resolution. In modern systems, this path typically includes a collimator or beam expander, galvanometer scanning mirrors, and an F-θ field lens.

Common Optical Path Configurations

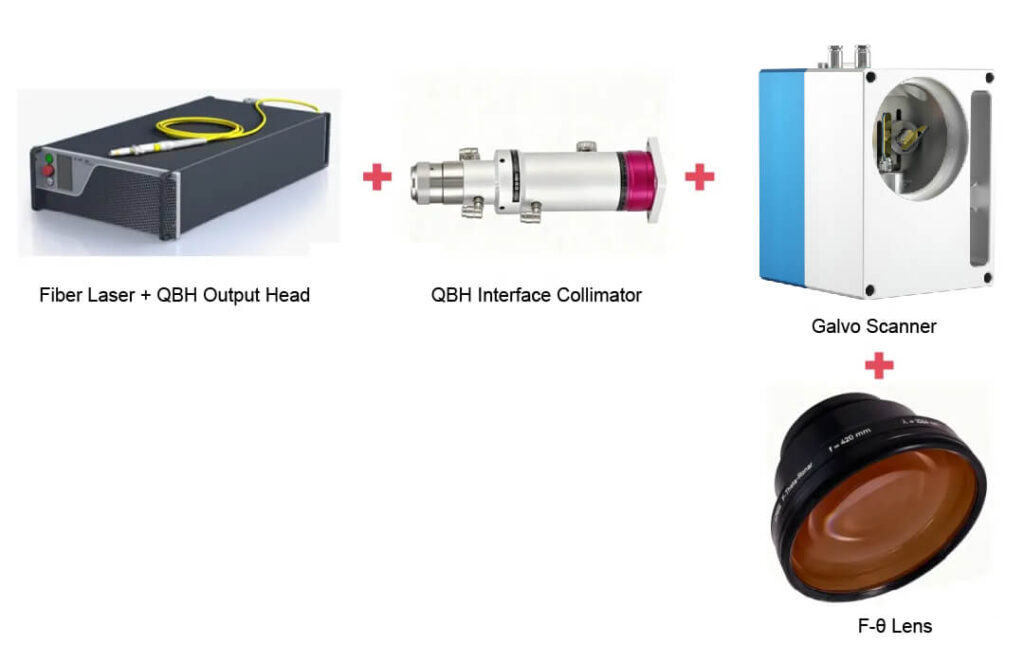

Two optical schemes dominate industrial setups:

| Scheme | Description |

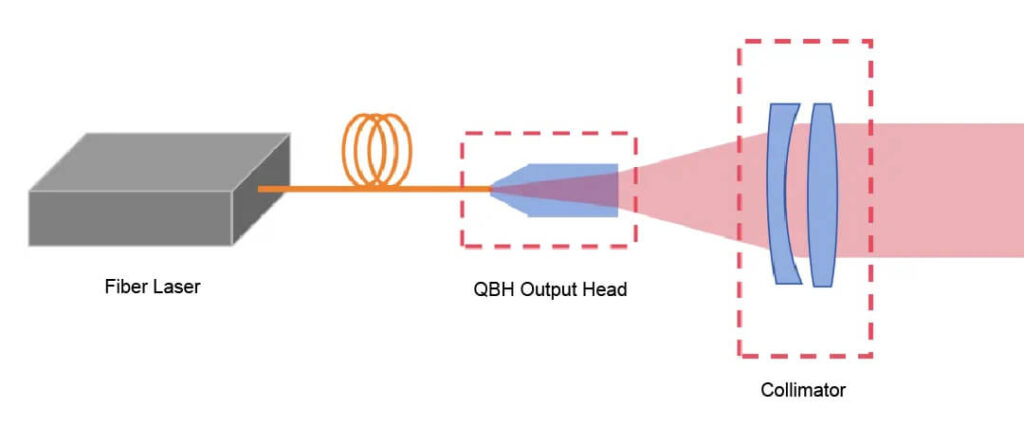

| QBH+ Collimator | A high-power fiber laser emits via a QBH connector. The beam passes through a collimator, then through scanning mirrors and a field lens that focuses onto the build plane. |

| QCS+Beam expander | A QCS head integrates collimation inside the laser output. A variable beam expander then adjusts beam diameter and divergence before scanning and focusing. |

Both configurations have strengths. The QBH + collimator layout allows easy swapping of optics for different spot sizes, while QCS + beam expander designs offer compactness and real-time adjustability.

Optical Design Considerations

QBH + Collimator

- Stable mechanical mount ensures repeatable alignment.

- Divergence can be fine-tuned by rotating the collimator.

- Suitable where quick hardware exchange is required.

- Integrated collimation reduces coupling losses.

- Beam size can be tuned on-the-fly via a variable expander.

- Compact, robust, and favored in high-precision multi-laser systems.

In practice, the choice depends on system architecture, available space, and required flexibility—key parameters in professional 3D printing optics design.

Requirements for Fiber Lasers in Metal 3D Printing

The laser is the “heart” of the printer. Its stability defines the success of the entire 3D printing optics chain.

- High Power and Stability: Typically 500–2000 W; fluctuation ≤ ±2 %.

- Excellent Beam Quality: TEM₀₀ mode with M² < 1.1 enables small, stable spots.

- Multi-Laser Coordination: Large printers (e.g., EOS M400-4) require identical beam profiles and perfect stitching across scan zones.

- Reliability: Modular design and remote diagnostics reduce downtime.

Core Components of 3D Printing Optics

Collimators

Convert diverging fiber output into a parallel beam.

Convert diverging fiber output into a parallel beam.

High-quality fused-silica lenses minimize thermal distortion and maintain focus stability.

Fine-adjustment mechanisms allow divergence tuning for precise focal control.

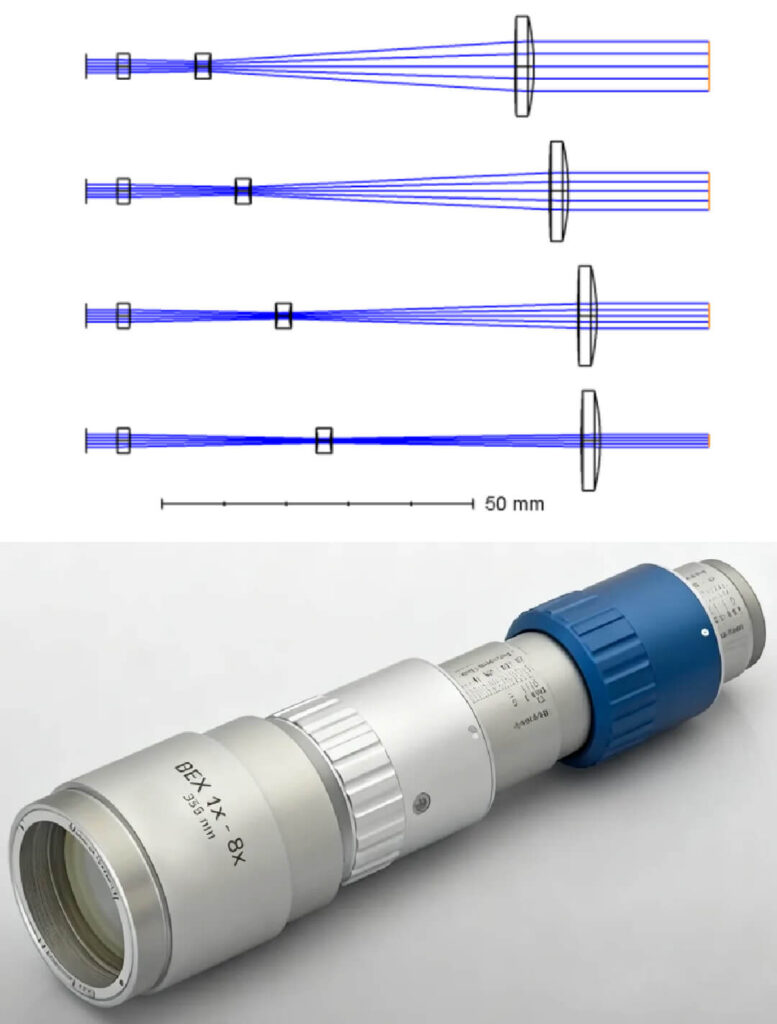

Beam Expanders

Adjust beam diameter and thus the final spot size at focus.

A Galilean 1–xx structure with fused-silica optics ensures durability and adjustable magnification.

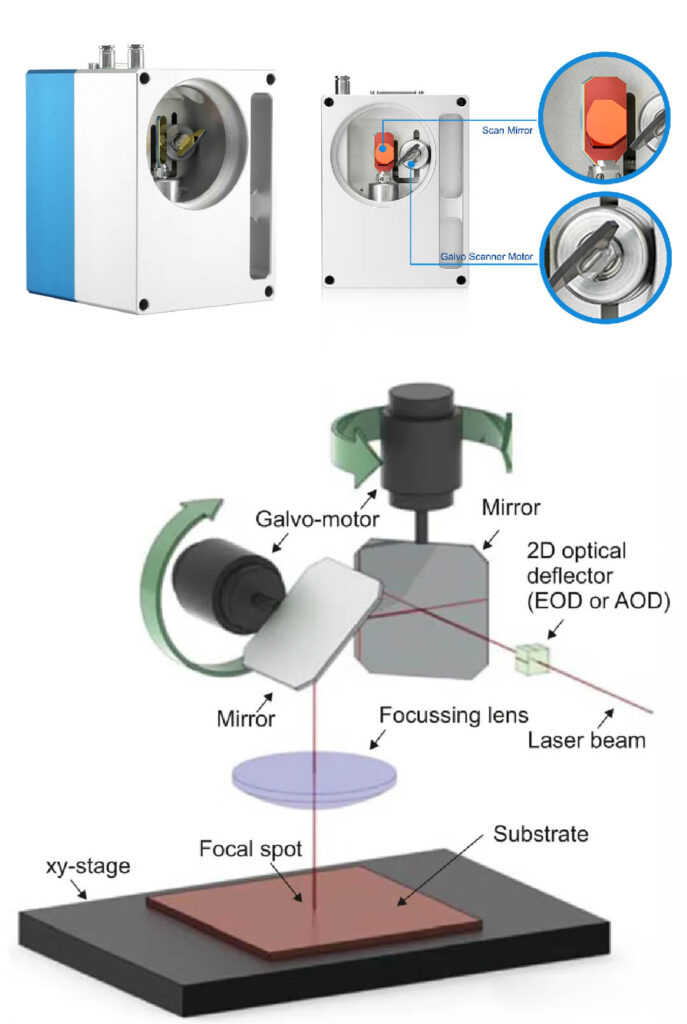

Galvo Scanners

Direct the laser beam to precise X-Y positions on the powder bed.

Direct the laser beam to precise X-Y positions on the powder bed.

Each mirror is servo-controlled for rapid, accurate movement.

Premium suppliers such as Scanlab, Raylase and SINO-GALVO provide excellent long-term stability.

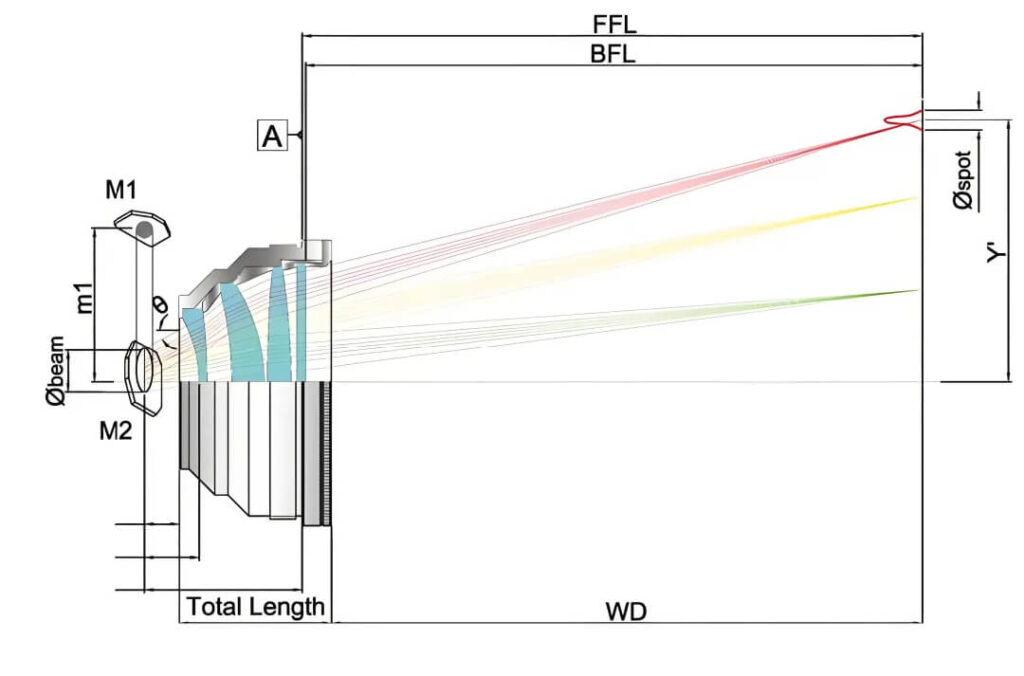

F-θ Field Lenses

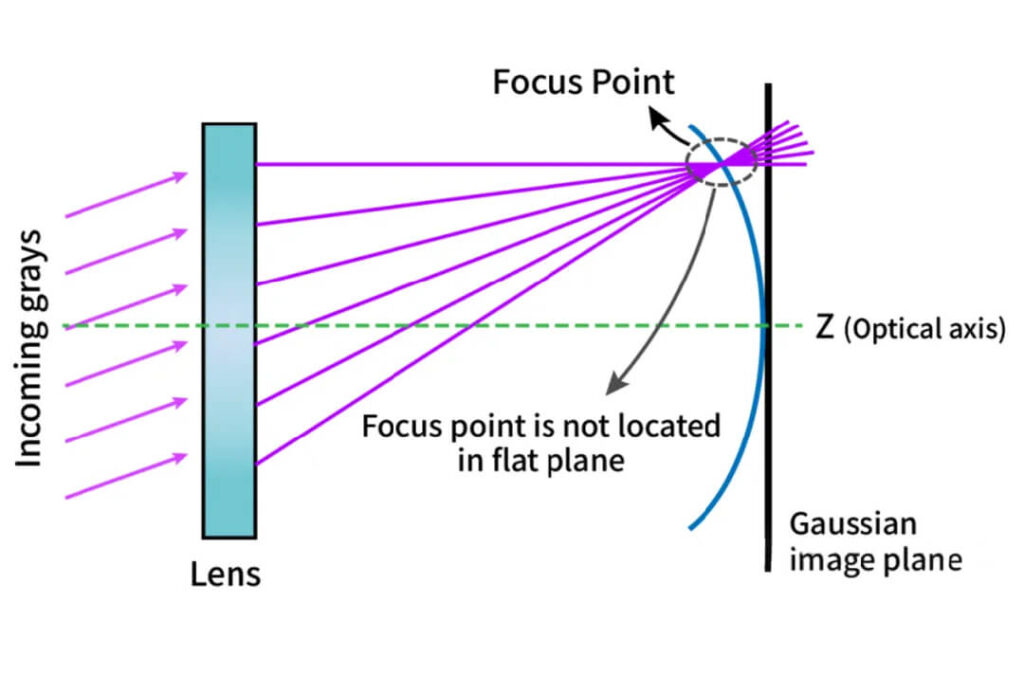

Focus the collimated beam onto a flat build plane, correcting for off-axis distortion.

Focus the collimated beam onto a flat build plane, correcting for off-axis distortion.

They maintain uniform spot size and energy density across the full scan area—an essential element in consistent 3D printing optics performance.

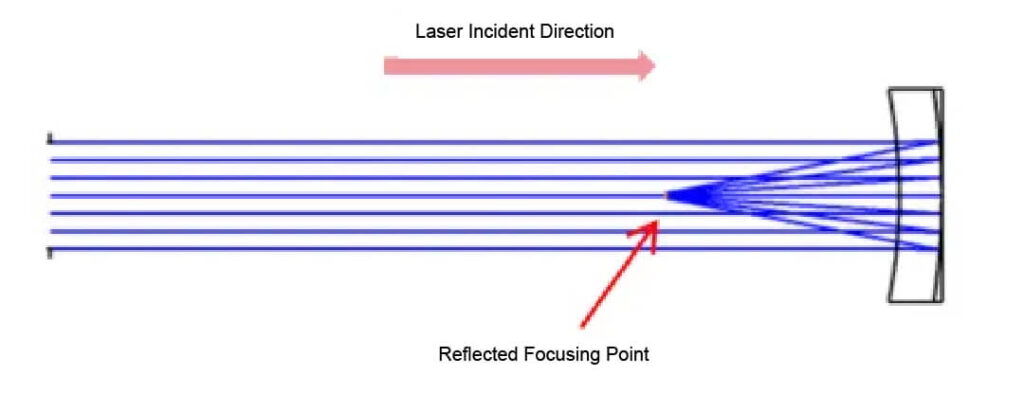

System Integration and Back-Reflection Control

Because optical components inevitably reflect small portions of light, designers must prevent back-reflections from striking critical elements like mirrors or sensors.

Proper 3D printing optics layout ensures these reflections are redirected safely, improving both performance and lifespan.

Summary

The optical path in metal 3D printing follows the classic structure—laser → collimation / beam conditioning → scanning → focusing—but demands extreme precision and thermal stability.

Modern 3D printing optics integrate advanced zoom, monitoring, and alignment technologies to maintain uniform energy density, minimize aberrations, and ensure repeatable, high-quality builds.

Ultimately, the success of metal additive manufacturing hinges on how effectively these optical systems deliver controlled light—turning photons into perfectly fused metal layers.