Laser marking on plastic is a fast, clean, and precise method used across industries to create permanent markings without physical contact or consumables. Given the wide variety of plastic materials—each with distinct thermal and chemical characteristics—it’s critical to select the right laser system to achieve optimal results.

Why Use Laser Marking on Plastic?

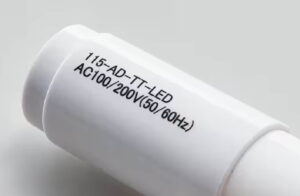

Laser marking is favored for plastic components due to its accuracy, durability, and non-invasive nature. Unlike ink printing or labels, which may fade or peel over time, laser marking provides long-lasting marks that resist chemicals, abrasion, and heat. Common materials used in laser-marked plastic include ABS, PET, polycarbonate, and epoxy. The laser doesn’t cut into the plastic—instead, it alters the surface through thermal or photochemical reactions depending on the laser type.

These marks are frequently seen on electronic housings, automotive parts, medical devices, and branded products. From serial numbers and QR codes to logos and control panel indicators, laser marking on plastic delivers high readability and visual appeal.

Suitable Laser Systems for Marking Plastic

Because plastics vary in how they absorb heat, not all lasers are equally suited for marking them. Excessive heat can deform the surface, so selecting a low-heat laser is essential. Three main types of laser markers are commonly used for plastic:

1. UV Laser Marker

UV lasers operate at 355 nm and enable “cold marking.” This short wavelength limits thermal impact, making UV lasers ideal for high-contrast, damage-free marking on sensitive plastics. They’re especially effective for fine text, medical instruments, and transparent materials.

2. Hybrid Laser Marker

Hybrid systems combine a YVO4 and fiber laser to deliver short, high-energy pulses at 1064 nm. This setup enables deep, detailed marking without burning or warping the plastic surface. Hybrid markers are widely used in industrial settings for their versatility and precision.

3. CO₂ Laser Marker

CO₂ lasers emit at 10.6 μm and are better suited for high-speed marking or engraving applications. They generate heat to melt the surface layer of plastics and other materials, creating either raised or recessed marks. While not suitable for all plastics, CO₂ lasers excel in branding and product labeling across wood, glass, and ceramics as well.

Techniques of Laser Marking on Plastic

Different marking techniques are used depending on the desired result, plastic type, and surface characteristics:

1.Dark Marking

By increasing laser absorption on light-colored plastics, dark marking creates crisp, high-contrast designs without material removal.

2.White Marking

Ideal for dark plastics, this method uses laser energy to scatter light within the material, producing bright, white marks.

3.Transparent Marking

Laser marking on semi-transparent plastics can result in either light or dark contrasts, depending on how the material interacts with the laser beam.

Plastic Laser Marking Methods

Laser marking plastic includes multiple sub-processes to fulfill different industrial needs:

• Paint Peeling

This technique removes a painted or printed surface layer to expose the underlying plastic. It’s common in automotive dashboards and offers flexibility by allowing design changes through software instead of plate reconfiguration.

• Surface Layer Removal

Also known as “engraving,” this removes thin surface coatings like aluminum or paint. It’s perfect for half-cuts or surface texturing, often replacing physical blades that wear out quickly or risk contamination.

• Color Development

This unique approach uses laser radiation to induce chemical changes that produce vivid colors directly on plastic without carving into it. It’s used for decorative or functional markings, such as on LSI chips.

• Laser Welding

This method fuses plastic parts using focused heat without contact or vibration. It’s ideal for joining clear and colored plastics with high bonding strength and minimal surface disruption.

Laser Processing Beyond Marking

In addition to marking, lasers are used for cutting, peeling, drilling, and cleaning plastic materials. These processes improve precision, reduce chemical use, and enhance production efficiency.

Emerging Trends in Plastic Laser Marking

Traditionally, plastic parts were labeled or printed, but those methods often involved consumables and lacked permanence. With the advancement of laser technologies, more manufacturers now prefer laser marking on plastic for its eco-friendliness and automation compatibility.

Modern laser marking machines come equipped with data storage, smart software, and the ability to perform micro-marking tasks. These improvements allow greater flexibility, precision, and adaptability, even for complex geometries and tiny components.

Conclusion

Laser marking on plastic offers unmatched advantages in precision, efficiency, and customization. Whether it’s used for aesthetic branding, traceability, or functional part identification, this technique continues to evolve, meeting the demands of fast-paced, high-tech industries. By choosing the right laser type and method, businesses can achieve clean, consistent, and durable results tailored to their plastic materials.