Laser drilling is widely used for creating precise, high-aspect-ratio holes in metals, ceramics, plastics, and composite materials. When paired with a galvo scanner—a high-speed beam-steering system—the efficiency, accuracy, and flexibility of laser drilling are significantly improved. This combination is reshaping modern manufacturing in aerospace, electronics, and medical device industries.

What Is Laser Drilling?

Laser drilling is a non-contact process that uses a focused laser beam to remove material and form holes through melting or vaporization. Unlike traditional mechanical drilling, laser drilling minimizes mechanical stress, allows for much smaller hole sizes, and works on hard or delicate materials with ease.

There are two primary methods:

- Percussion Drilling: Multiple pulses at a single point

- Trepanning or Helical Drilling: Beam movement along a defined path

What Is a Galvo Scanner?

A galvanometer scanner, or galvo scanner, uses high-speed mirrors controlled by electromagnetic motors to steer the laser beam with great precision. Instead of moving the workpiece or the laser head, the galvo moves the beam itself, enabling ultra-fast positioning and dynamic hole creation.

Why Use Galvo Scanners for Laser Drilling?

Integrating a galvo scanner into your laser drilling system offers a wide range of benefits:

✔️ High Drilling Speed

Galvo scanners can move the laser beam at several meters per second, enabling rapid hole drilling—even for complex arrays or high-volume production.

✔️ Ultra-Precise Beam Positioning

Mirror movements are controlled with micron-level accuracy, ensuring consistent hole size, depth, and spacing.

✔️ Non-mechanical Movement

No need to move the laser head or worktable, which reduces wear and simplifies system integration.

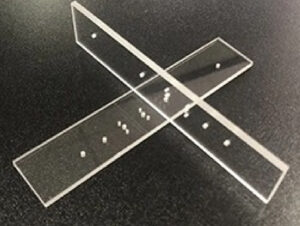

✔️ Multi-hole Patterns with One Setup

Galvo systems can execute pre-programmed patterns or variable spacing holes instantly, ideal for mesh structures, nozzles, filters, or microfluidic channels.

✔️ Compatible with Multiple Laser Types

Whether using fiber, UV, or ultrafast (ps/fs) lasers, galvo scanners provide seamless beam delivery.

Applications of Galvo-Based Laser Drilling

Aerospace

Create cooling holes in turbine blades and combustion components with high heat resistance and precision.

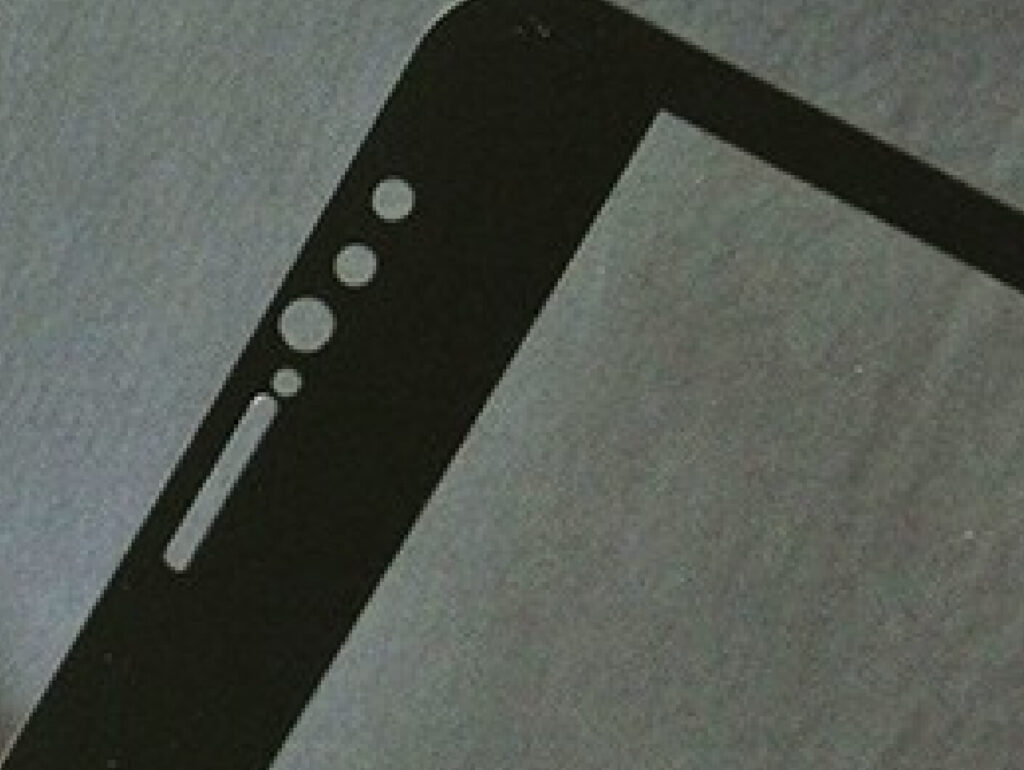

Medical Devices

Drill micro-holes in needles, drug-delivery components, and stents with minimal heat-affected zones.

Electronics

Form microvias in printed circuit boards (PCBs) and drill patterns in ceramic or silicon wafers for semiconductor packaging.

Automotive

Laser-drill injector nozzles, filter screens, and high-performance components for fuel efficiency.

Energy & Battery Tech

Use high-speed drilling for vent holes, electrode perforation, and separator material processing.

Technical Considerations

To achieve optimal laser drilling with a galvo system, consider:

- Laser Type: Short-pulse (ns/ps/fs) lasers for minimal heat-affected zones

- Beam Delivery: F-theta lenses to ensure flat-field focus across the scan area

- Software Control: Synchronize laser pulses with galvo motion for consistent drilling

- Cooling & Extraction: Remove debris and manage thermal effects in high-density drilling

Compared to Traditional CNC Drilling

| Feature | Galvo Laser Drilling | CNC Drilling |

| Speed | Very high | Moderate |

| Hole Size | Down to microns | Limited by tool size |

| Material Stress | None (non-contact) | Mechanical stress |

| Flexibility | Software-programmable | Manual/tool dependent |

| Maintenance | Low (no tool wear) | High (tool wear/breakage) |

Conclusion

Galvo scanner-based laser drilling is transforming advanced manufacturing by delivering unmatched speed, accuracy, and scalability. From microelectronics to aerospace, this technology enables high-volume, high-quality hole production with minimal material waste or wear. For manufacturers seeking to optimize precision and throughput, galvo-controlled laser drilling is the future-ready solution.