PV Energy Storage in China

Photovoltaic energy storage is a key area for China’s green energy transition under the dual-carbon policy. Policies like the “Smart Photovoltaic Industry Innovation Plan (2021–2025)” and the “Implementation Plan for High-Quality New Energy Development” make wind and solar storage a national focus.

Picture 1: China’s photovoltaic industry is growing rapidly.

China has maintained the world’s largest PV installed capacity for nine consecutive years. For example, the Qinghai Talatan PV Power Station covers 608 km².

Production: CIGS Thin-Film Cleaning

Third-generation CIGS thin-film solar cells are used alone or with perovskite for tandem cells. During production, the molybdenum layer under glass must be selectively exposed for conductive tape welding or glue bonding.

Laser cleaning solar panels can remove just a few microns of the CIGS and TCO layers without damaging Mo, enabling precise production.

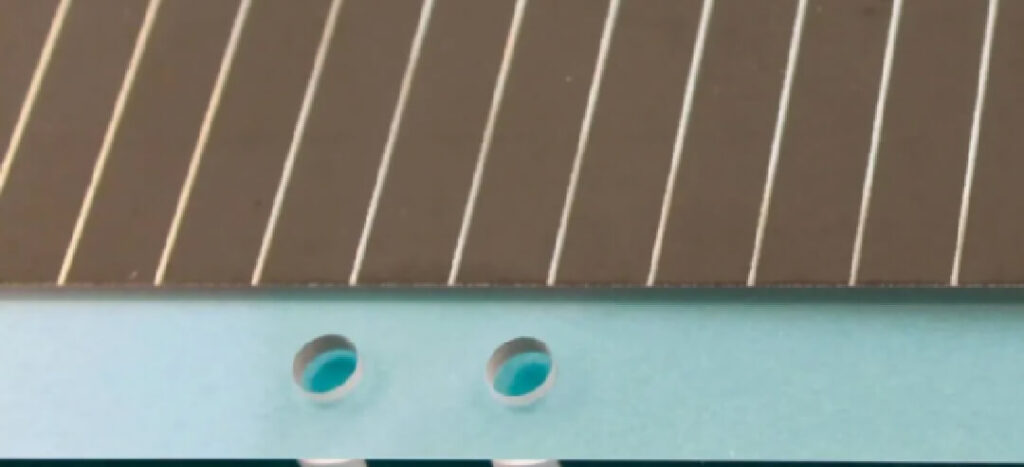

Picture 2: Molybdenum layer in CIGS thin-film production

Laser cleaning also removes edge stacks during encapsulation, preventing short circuits and keeping glass surfaces clean for durable CIGS modules

O&M: Automated Dust Removal

PV plants are often in dusty regions, which can reduce efficiency by 7–40%. Traditional cleaning methods like manual brushing or water washing are inefficient, inconsistent, and costly.

Laser cleaning solar panels with robots offers water-free, non-contact cleaning, avoiding physical damage and improving overall efficiency.

Picture 3: Robotic laser cleaning avoids surface damage and blind spots.

Recycling: Delamination of Old Modules

First-generation silicon PV modules are reaching end-of-life (~15 years). By 2030, global PV module recycling will reach 8 million tons, rising to 80 million tons by 2050.

Modules contain glass (~70%), aluminum (~18%), silicon (~3.5%), copper (~1.5%), rare metals (~1%), and encapsulants (~6%).

Traditional methods—physical separation or solvent soaking—are inefficient or environmentally risky.

Laser cleaning solar panels can delaminate silicon from adhesive layers without damage, producing cleaner glass surfaces and near 100% silicon recovery.

![]() Picture 4: Laser cleaning is the most effective method for adhesive removal.

Picture 4: Laser cleaning is the most effective method for adhesive removal.

Advantages of Laser Cleaning

- Non-contact & precise – avoids scratches.

- Eco-friendly – no chemicals or water needed.

- High precision – ideal for thin-film layers.

- Automation-ready – compatible with robotic systems.

- Cost-effective – reduces consumables and maintenance.

Galvo Scanners for Precision

Galvo scanners control the laser beam’s X-Y movement with high speed and accuracy.

They enable:

- Fast scanning over large panels

- Precise beam positioning

- Flexible pattern control

- Easy integration into automated lines

High-speed galvo scanners make laser cleaning solar panels practical for industrial production and maintenance.

Conclusion

Laser cleaning solar panels is transforming production, O&M, and recycling. With precision galvo scanners, it delivers speed, safety, and sustainability, making it an ideal solution for the photovoltaic industry.

Contact Sino-Galvo to explore high-performance galvo scanners optimized for industrial laser cleaning systems.