What Is Laser Surface Treatment?

Laser surface treatment is a non-contact, flexible, and eco-friendly processing method that uses focused laser beams to modify a material’s surface properties.

Compared with traditional mechanical or chemical processes, laser surface treatment offers high precision, minimal heat-affected zones, zero consumables, and low environmental impact. Explore our solutions for surface treatment to achieve high-speed, high-precision performance.

Beyond the well-known laser cleaning technology, which removes oxides and contaminants, laser processing enables a wide range of applications — from surface hardening and micro-texturing to functional coatings and decorative color marking.

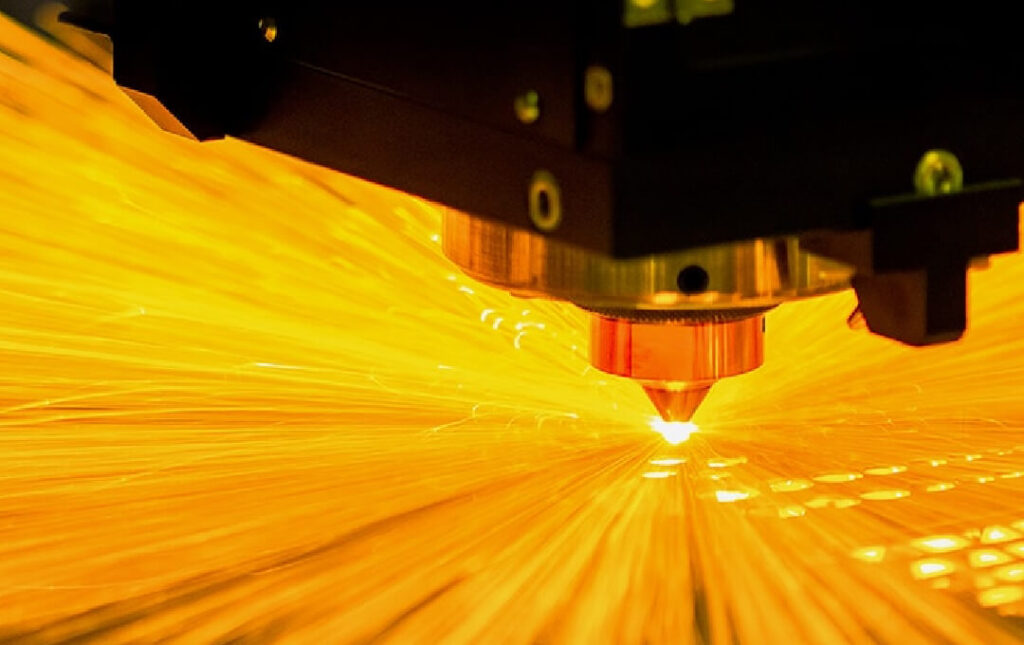

Laser Hardening – Precision Surface Strengthening

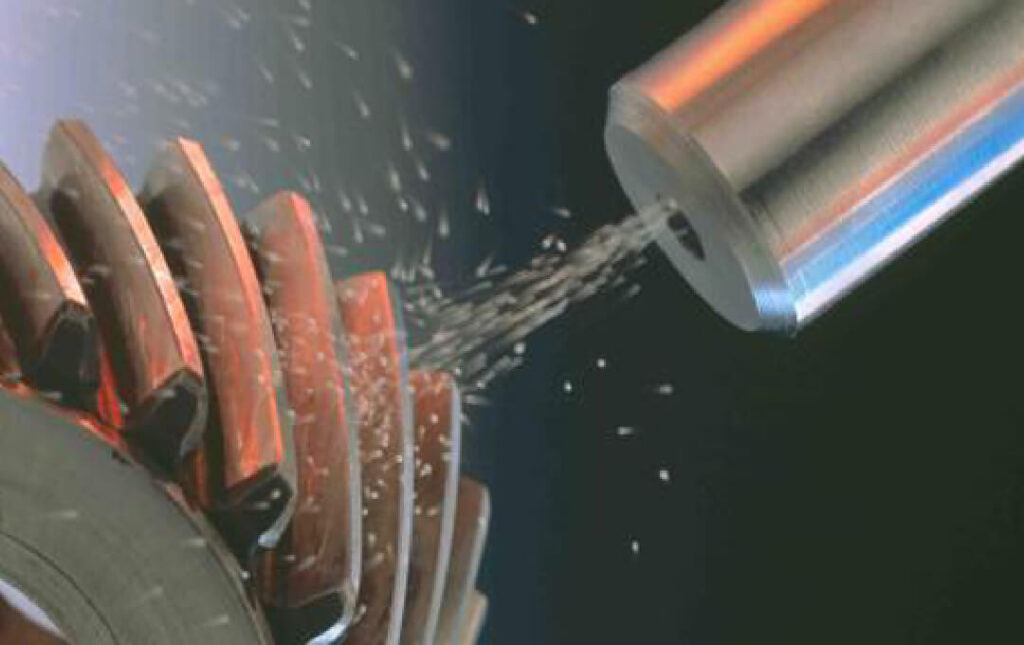

Laser hardening is a high-precision heat treatment process used for parts like camshafts, gears, and bending tools that endure heavy mechanical stress.

The laser heats the steel surface to just below its melting point (900–1400 °C), transforming it into austenite. As the laser beam moves, rapid self-quenching creates martensitic microstructures, significantly increasing hardness and wear resistance.

Advantages of laser hardening:

- Localized heat input minimizes distortion and warping

- Precise hardening of complex shapes and small areas

- Controlled process ensures uniform hardness and repeatability

- Instant geometry adjustment without changing optical setups

Typical hardened depth ranges from 0.1–1.5 mm, and can exceed 2.5 mm in some alloys.

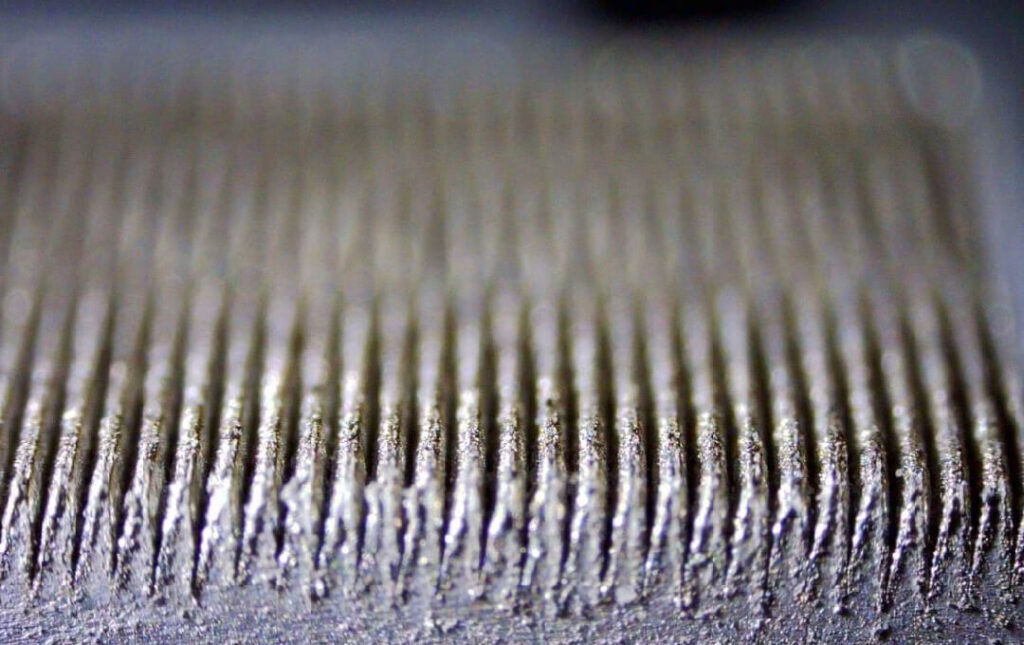

Laser Texturing – Functional Surface Engineering

Laser texturing, also known as laser roughening, uses short-pulse or ultrashort-pulse lasers to form micro- and nano-scale surface structures.

These textures improve adhesion, alter friction properties, and add functionalities such as hydrophobic or hydrophilic behavior.

Applications include:

- Automotive panels – enhancing paint adhesion via micro-dimple arrays

- Roller surfaces – improving wear resistance and coating quality

- Functional engineering – tailoring surface friction and conductivity

Laser texturing is repeatable, chemical-free, non-contact, and delivers micron-level precision — making it ideal for modern green manufacturing.

Laser Color Marking – Decorative and Functional Marking

Laser color marking, also called laser tempering marking, creates oxide interference layers on metal surfaces.

By precisely heating the metal just below its melting temperature, thin oxide films form that display brilliant interference colors — blue, yellow, violet, or green — depending on thickness.

Key advantages:

- Temperature stability up to 200 °C

- High security for anti-counterfeiting and traceability (UDI marking)

- No material removal or substrate damage

- Fully controllable color spectrum via laser parameters

It is widely used in medical devices, luxury goods, and precision tools.

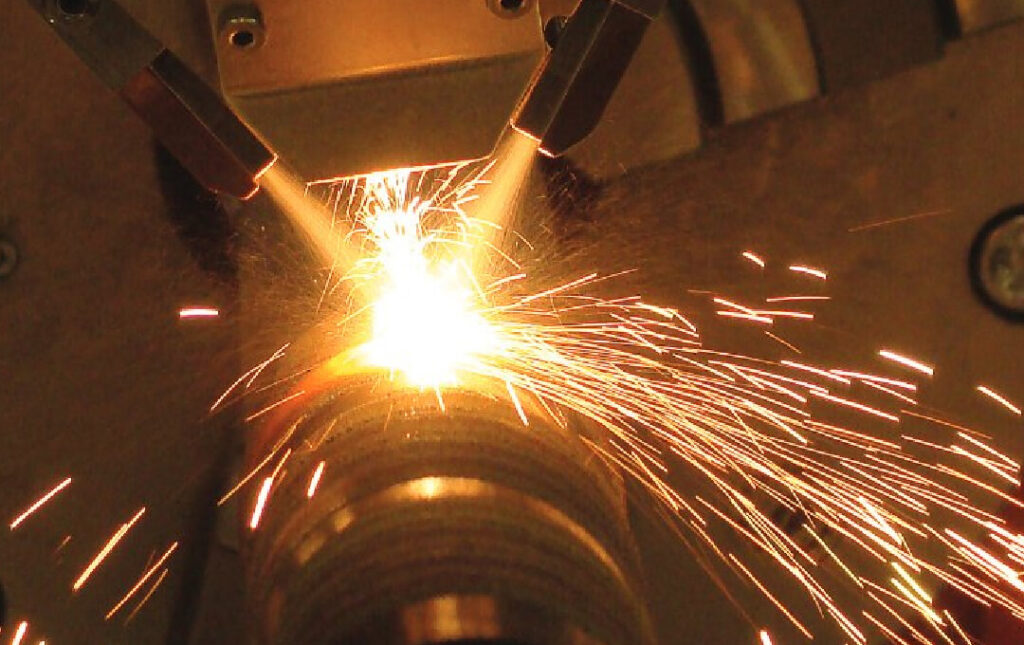

Laser Cladding – Additive Surface Manufacturing

Laser cladding (a form of additive manufacturing) is used to deposit metal or metal–ceramic coatings for repair, protection, or performance enhancement.

The laser creates a molten pool on the substrate, while metal powder is fed through a nozzle and fused with the base material.

Advantages of laser cladding:

- Restores worn or damaged parts like turbine blades, molds, and valves

- Improves resistance to wear, corrosion, and fatigue

- Minimizes dilution and heat input compared with welding

- Enables high-speed laser metal deposition (HS-LMD) for large areas (up to 1500 cm²/min)

This process saves cost and material, especially for nickel, titanium, and other high-value alloys.

Laser Heat Treatment with VCSEL Arrays – High-Precision Thermal Control

New-generation VCSEL (Vertical Cavity Surface Emitting Laser) arrays enable large-area, uniform, and precisely controlled heating.

Each module contains thousands of micro-lasers, generating several kilowatts of infrared power with an intensity around 100 W/cm².

Key industrial applications:

- Drying or sealing battery foils and pouch cells

- Preheating solar cell wafers

- Precise annealing of steel or silicon wafers

Compared with conventional ovens or induction heating, VCSEL-based laser heat treatment offers higher precision, faster response, and significant energy savings.

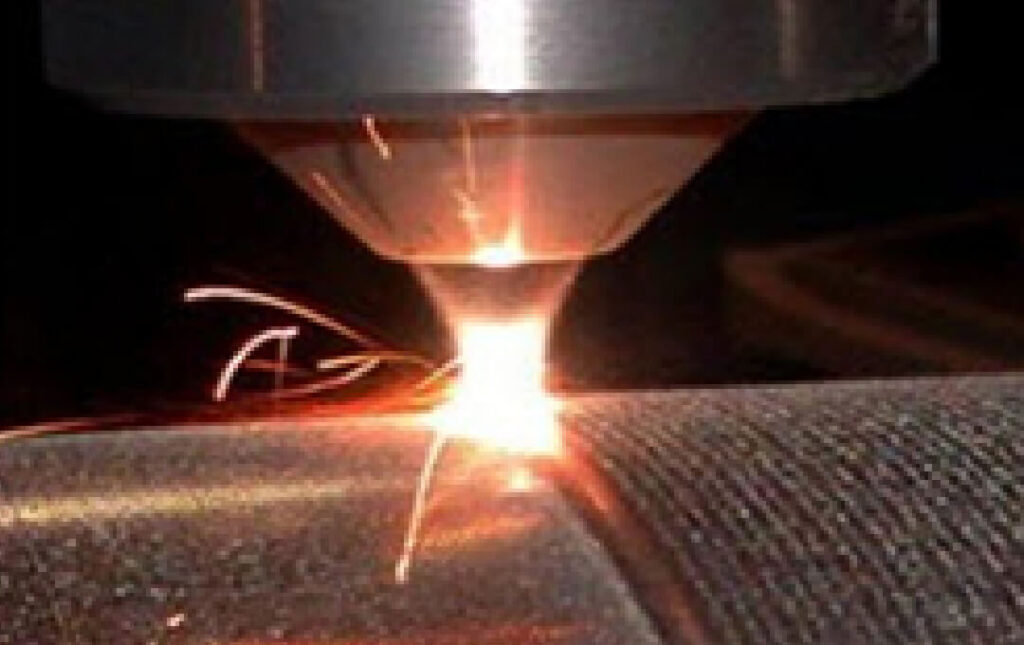

Laser Polishing – Smoother Surfaces with Controlled Remelting

Laser polishing smooths rough surfaces by controlled surface remelting and resolidification.

When the laser melts the top layer, capillary forces and surface tension redistribute molten material to fill valleys and reduce surface roughness.

Example:

Femtosecond-laser-assisted polishing of RB-SiC mirrors achieved 4.45 nm surface roughness in just 4.5 hours — three times faster than mechanical polishing.

Applications:

- Precision optics and mirrors

- Injection molds, turbine blades, camshafts

Laser Peening – Strengthening Through Shock Waves

Laser peening (LSP), or laser shock hardening, uses high-energy, short-pulse lasers (λ = 1053 nm) to generate plasma explosions on the metal surface.

The resulting shock waves induce compressive residual stresses and grain refinement, improving fatigue life and strength without surface damage.

Benefits over traditional shot peening:

- Directional, precisely controlled energy application

- Extremely high impact pressure (several GPa)

- Power density up to 10–50 GW/cm²

- No surface contamination or microcracks

Widely used in aerospace, jet engines, and high-stress structural components.

Conclusion: Expanding the Frontiers of Laser Surface Technology

Laser cleaning is only the beginning of what lasers can do.

From hardening and cladding to micro-texturing, polishing, and peening, laser surface treatment technologies offer unparalleled precision, sustainability, and material efficiency.

As industries demand greener, smarter, and more reliable production methods, laser surface treatment will continue to transform the way we design, repair, and enhance materials.