Introduction

As the global automotive industry accelerates toward electrification, the performance, safety, and cost of power batteries determine the competitiveness of electric vehicles (EVs). Battery manufacturing is a complex process that integrates materials science, electrochemistry, and precision mechanics. Among all stages, high-quality joining technology is the key to ensuring safety and consistency.

Traditional joining methods such as resistance welding and ultrasonic welding are increasingly limited when facing mass production and the processing of high-conductivity materials like copper and aluminum. Their drawbacks include wide heat-affected zones, narrow process windows, and inconsistent quality.

By contrast, battery pack laser welding features high energy density, controllable heat input, non-contact operation, and easy automation—perfectly meeting the strict demands of EV battery manufacturing. This article outlines its applications across different production stages and its role in advancing the power battery industry.

Applications in Cell Manufacturing

The cell is the fundamental unit of a power battery. Its manufacturing precision and sealing quality directly affect battery safety and performance. Laser welding plays a crucial role in electrode connection and cell sealing.

(1) Electrode tab welding

After winding or stacking, dozens or even hundreds of positive (aluminum foil) and negative (copper foil) electrode tabs must be welded to form a stable electrical path with external terminals (see Fig.1). Laser welding provides low-resistance, high-strength joints with minimal heat impact, preventing damage to separators and active materials and maintaining electrochemical performance.

Fig.1 Laser Welding of Lithium Battery Cells

Fig.1 Laser Welding of Lithium Battery Cells

(2) Cell sealing

Laser welding is widely used for hermetic sealing in prismatic and cylindrical cells. By precisely controlling power, speed, and focus, it produces smooth, dense weld seams that prevent electrolyte leakage and moisture ingress, ensuring long-term stability.

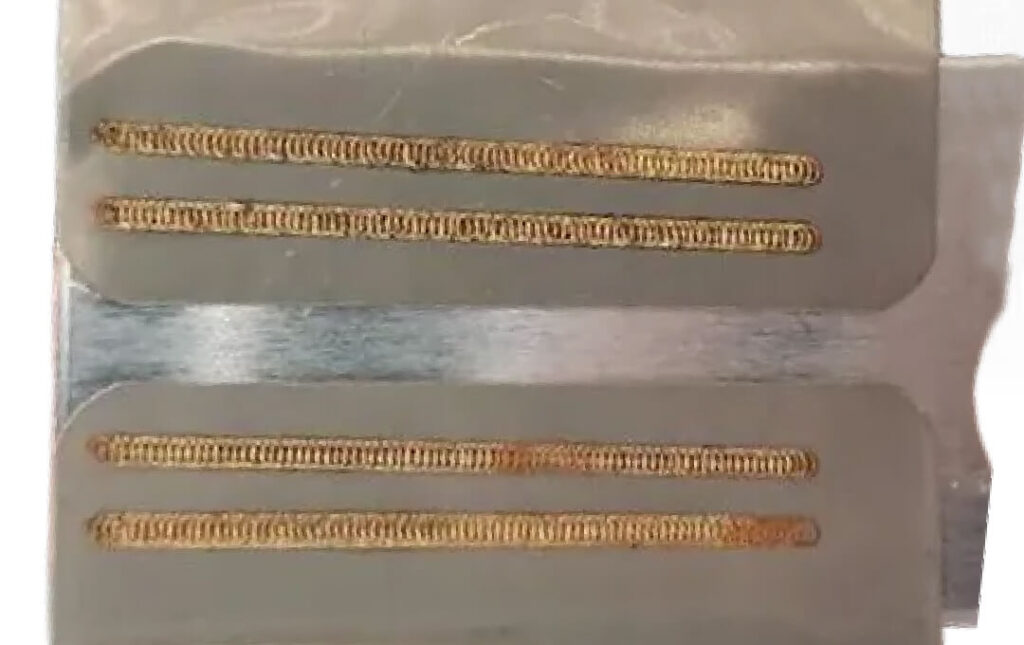

For pouch cells, laser welding is used for top and side sealing, joining electrode tabs with nickel-plated copper or aluminum connectors. Its non-contact nature ensures high sealing efficiency without damaging the laminated aluminum film (see Fig.2).

Fig.2 Laser Welding Sample of Pouch Cell Tabs

Fig.2 Laser Welding Sample of Pouch Cell Tabs

Applications in Module and Battery Pack Assembly

In the module and battery pack stages, battery pack laser welding is essential for both electrical interconnection and structural joining.

(1) Electrical connections

Cells are connected in series or parallel by welding busbars—usually aluminum or copper—to the cell terminals. Key challenges include:

- Material properties: Copper and aluminum have high reflectivity and thermal conductivity, making them difficult to weld.

- Dissimilar metal joining: Copper-to-aluminum welding tends to form brittle intermetallic compounds (IMCs), reducing reliability.

To solve these problems, techniques such as wobble laser welding, hybrid laser-arc welding, and green/blue laser sources have been developed. These methods enhance energy absorption, stabilize the molten pool, and control IMC formation—achieving reliable, low-resistance connections.

Fig.3 Laser Welding of Lithium Battery Busbars

Fig.3 Laser Welding of Lithium Battery Busbars

(2) Structural connections

Laser welding also joins structural components such as module side plates, end plates, and battery pack housings. Compared with bolts or rivets, it achieves higher integration and mechanical strength, improving vibration and impact resistance.

Additionally, in battery management systems (BMS), laser welding ensures stable and durable connections for voltage and temperature sensor circuits.

Conclusion

Battery pack laser welding integrates high precision, speed, and reliability throughout the entire EV battery manufacturing process. From micro-scale electrode tab welding to large structural joints, it ensures both performance and durability.

By addressing the challenges of copper and aluminum welding and enabling automated, high-efficiency production, laser welding safeguards the electrochemical integrity of batteries while reducing manufacturing costs. Its continuous development is driving improvements in energy density, safety, and cost-effectiveness—fueling the evolution of the global electric vehicle industry.

Optimize your battery pack laser welding line with our high-power galvanometer—designed for precision and reliability.