Femtosecond laser micromachining has earned the title of the “Swiss Army knife of micro-/nano-fabrication.” With its ultrahigh precision, negligible thermal damage, and compatibility with almost any material, this technology is rapidly transforming microelectronics, optical manufacturing, biomedicine, and advanced materials processing.

This article provides a clear and accessible introduction to the working principles, key advantages, major applications, and future trends of femtosecond laser micromachining.

How Femtosecond Laser Micromachining Works?

A femtosecond laser pulse lasts only 10⁻¹⁵ seconds, which is one million times shorter than a typical nanosecond laser pulse. This extremely short duration leads to two important physical phenomena:

1) Nonlinear absorption (instantaneous energy deposition)

The material has no time to absorb heat—the laser breaks atomic bonds directly.

➡ This eliminates heat diffusion, enabling true cold ablation.

2) Ultrahigh peak power (localized micro-explosion)

The energy is concentrated within an extremely short time, creating a confined plasma and micro-explosive effect.

➡ This allows the creation of sub-micron structures with exceptional accuracy.

In simple terms:

A femtosecond laser does not “burn” material—it precisely breaks molecular bonds.

This is the fundamental reason it achieves high precision with minimal thermal damage.

Key Application of Femtosecond Laser Micromachining

Microelectronics and Semiconductor Processing

- Microchannels, microelectrodes, MEMS

- Silicon, glass, ceramic micromachining

- Circuit repair and laser trimming

Benefits: high precision, no heat-affected zone, and compatibility with hard and transparent materials.

Biomedicine and Life Sciences

Because the process introduces virtually zero thermal damage, femtosecond lasers are ideal for biological tissues:

- Femtosecond-assisted LASIK

- Cell cutting, chromosome micro-dissection

- Microsurgery on nerves and micro-vessels

Advantages: no carbonization, no charring, and minimal collateral damage.

Surface Micro- / Nano-structuring

Femtosecond lasers can create functional microstructures on material surfaces:

- Superhydrophobic / superhydrophilic surfaces

- Anti-adhesion, anti-icing, anti-corrosion textures

- Metal blackening (black metal)

This area is expanding rapidly in aerospace, energy systems, and functional coatings.

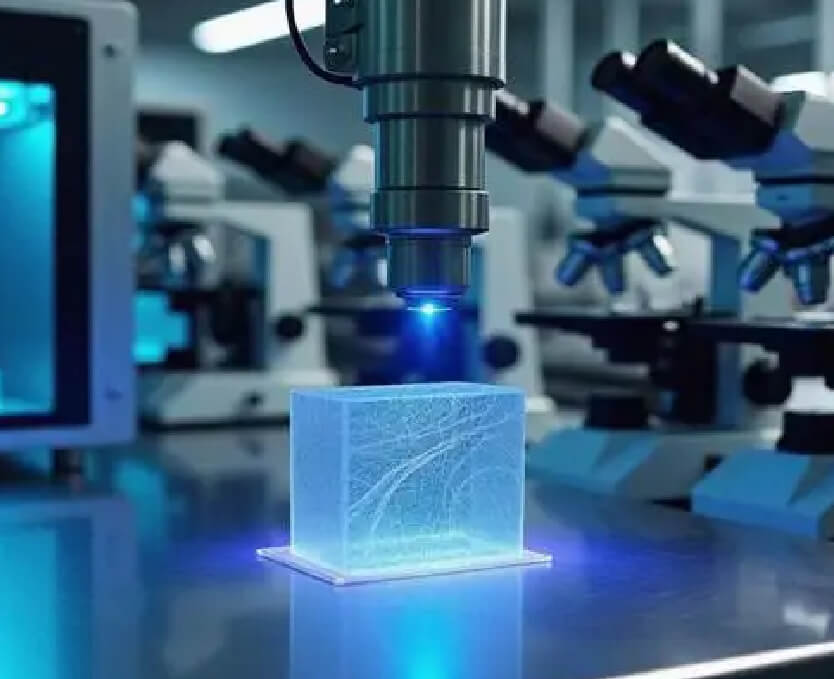

Optical Components and Photonic Device Fabrication

Femtosecond lasers can perform true 3D micromachining inside transparent materials, enabling:

- Optical waveguides

- Fiber Bragg gratings

- Microlens arrays

- Photonic crystals

Many of these complex 3D optical structures are impossible to fabricate using traditional techniques.

Other Emerging Applications

- Repair of turbine blades in aerospace

- Non-thermal cultural heritage cleaning

- Thin-film micromachining

- Precision drilling of transparent materials (e.g., display glass, cover glass)

Major Technical Advantages of Femtosecond Laser Micromachining

Advantage 1: True Non-thermal Processing

No melting, no heat-affected zone, and no microcracks.

→ Ideal for heat-sensitive materials, biological tissues, and optical glass.

Advantage 2: Exceptional Precision (micro- to nano-scale)

Capable of producing:

- <1 μm micro-holes

- 3D microstructures

- Selective layer removal in multilayer materials

Perfect for high-end manufacturing that demands extreme accuracy.

Advantage 3: Universally Compatible with Nearly All Materials

Metals, glass, ceramics, polymers, composites, transparent materials—

femtosecond lasers can machine almost anything.

Advantage 4: Highly Controllable and Flexible

Adjusting pulse width, repetition rate, or scanning path instantly produces different microstructures.

Ideal for R&D, prototyping, and high-value small-batch manufacturing.

Future Trends of Femtosecond Laser Micromachining

- Higher Repetition Rates and Higher Throughput

Systems have progressed from tens of kHz to MHz-level repetition rates—

micro-machining efficiency increasing by 10× to 100×.

- Expanding Material Compatibility

Including 2D materials (graphene), topological materials, functional ceramics, and advanced composites.

- Integration with AI and Precision Motion Platforms

AI-driven parameter optimization, intelligent compensation, and automated micro-machining are emerging.

- Mass Commercialization

Femtosecond laser systems are entering production lines for:

- Smartphone glass processing

- Medical device manufacturing

- Optical communication components

Within the next 5–10 years, femtosecond laser micromachining will likely become a standard tool in advanced manufacturing.

In Summary

Femtosecond laser micromachining represents one of the closest technologies we have to true non-destructive precision machining.

It allows us to “sculpt materials freely” at the microscopic scale, opening new possibilities for next-generation microelectronics, photonics, biomedical devices, and advanced materials manufacturing.