Laser Drilling

The Principle of laser drilling

Laser drilling is the use of high-power-density laser beams to irradiate the processed material, so that the material is quickly heated to the vaporization temperature, and evaporates to form holes. Compared with conventional drilling methods, it has the following significant advantages: ①Laser drilling speed is fast, high efficiency, and good economic benefits. ②Laser drilling can obtain a large depth-to-diameter ratio. ③ There are many types of machinable materials, such as ceramics, composite materials, superalloys, etc. ④ Non-contact processing, no tool loss, low cost of use. ⑤Laser drilling is suitable for group hole processing with large quantity and high density. ⑥ Small holes can be processed on the inclined surface of difficult-to-machine materials with laser.Application of laser drilling

In actual production applications, laser drilling has many similarities with traditional mechanical drilling, such as the same use of three-axis and five-axis motion control, and the same automatic processing of NC programs. The laser focus is like a tangible and intangible cutter head, the energy density of the laser is the hardness of the cutter head, and the machine tool setting is to align the laser focus.Glass drilling

Our company currently provides optical fiber FL2208-3D-65 and green light GL2208-3D-100 scanning systems, which can be used for glass drilling.

Sorry, we couldn't find any posts. Please try a different search.

Laser Drilling

The Principle of laser drilling

Laser drilling is the use of high-power-density laser beams to irradiate the processed material, so that the material is quickly heated to the vaporization temperature, and evaporates to form holes. Compared with conventional drilling methods, it has the following significant advantages:

①Laser drilling speed is fast, high efficiency, and good economic benefits.

②Laser drilling can obtain a large depth-to-diameter ratio.

③ There are many types of machinable materials, such as ceramics, composite materials, superalloys, etc.

④ Non-contact processing, no tool loss, low cost of use.

⑤Laser drilling is suitable for group hole processing with large quantity and high density.

⑥ Small holes can be processed on the inclined surface of difficult-to-machine materials with laser.

Application of laser drilling

In actual production applications, laser drilling has many similarities with traditional mechanical drilling, such as the same use of three-axis and five-axis motion control, and the same automatic processing of CNC programs. The laser focus is like a tangible and intangible cutter head, the energy density of the laser is the hardness of the cutter head, and the machine tool setting is to align the laser focus.

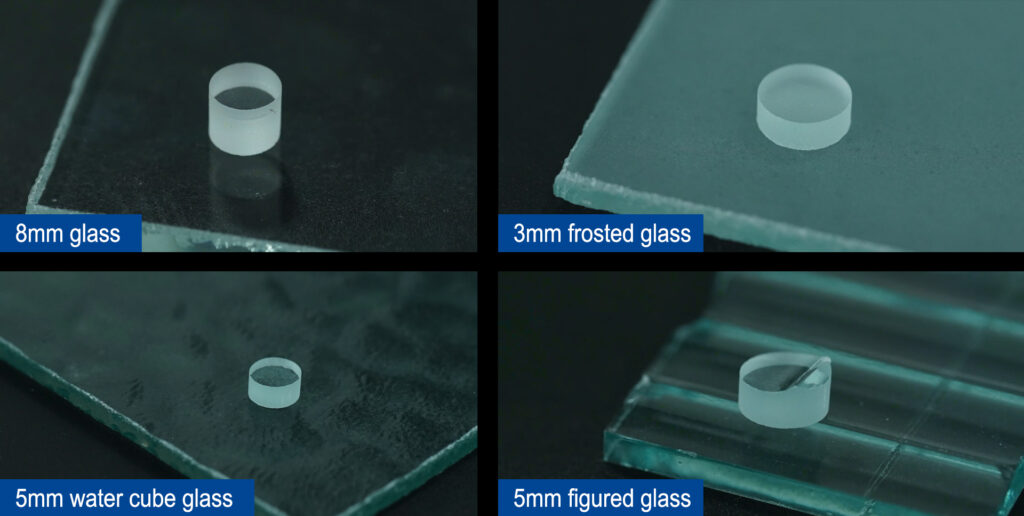

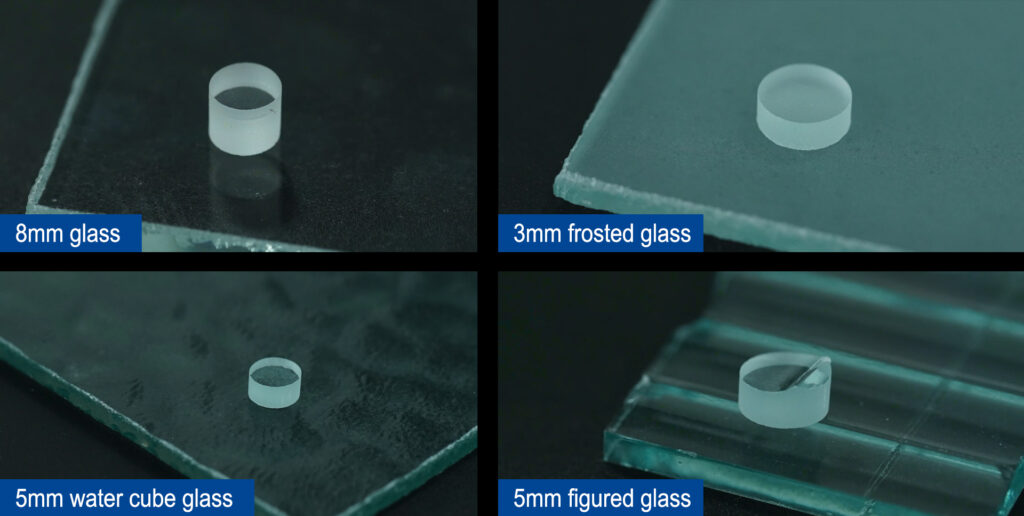

Glass drilling

Our company currently provides optical fiber FL2208-3D-65 and green light GL2208-3D-100 scanning systems, which can be used for glass drilling.