Laser cleaning rust removal

- What is laser cleaning/laser ablation?

- How does laser cleaning rust removal work?

- Why choose laser cleaning rather than traditional techniques?

- What are the types of laser cleaning

- What factors will affect the laser cleaning effect?

- What are the key components of a laser cleaning system?

- Common questions about laser cleaning

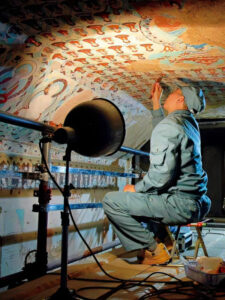

- Application of Laser Cleaning

What is laser cleaning/laser ablation?

Laser cleaning (also known as laser ablation), refers to the use of high-frequency and high-energy laser beams to irradiate the surface of the workpiece to instantly evaporate or peel off oil, rust or coatings on the surface, thereby achieving a clean laser process.

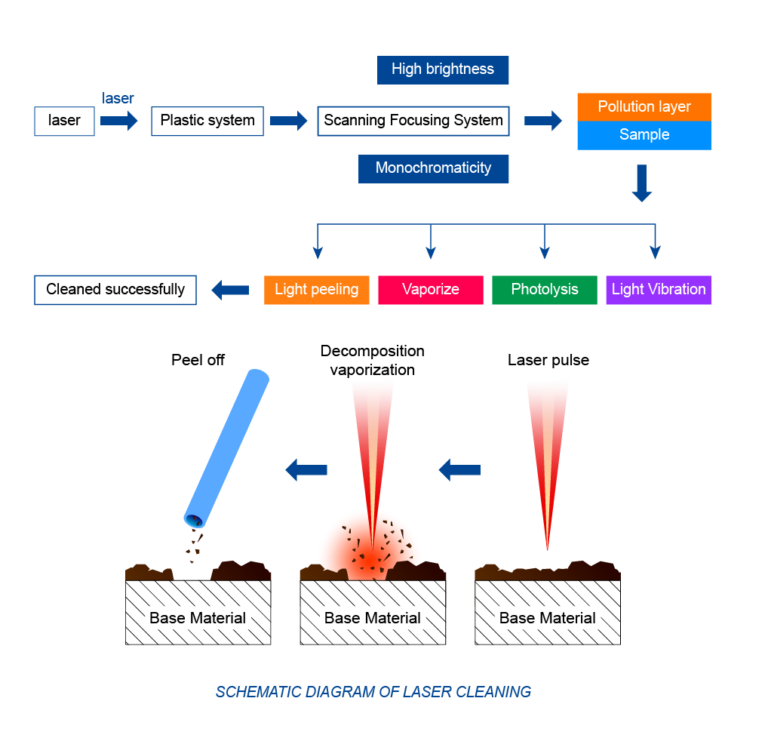

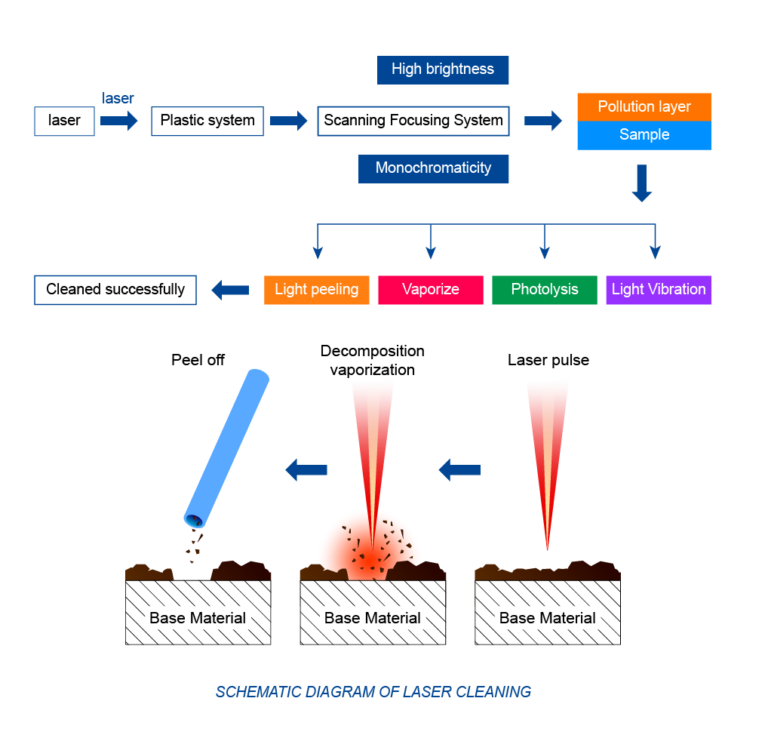

How does laser cleaning rust removal work?

Laser cleaning is to use the characteristics of high laser intensity, high energy density, strong focusing and good directionality to focus the beam to a small area, and use the vibration of the laser pulse, thermal expansion, and molecular photolysis., to overcome the binding force between the dirt and the surface of the substrate, so that the dirt can be separated from the surface to achieve the purpose of cleaning.

· Photolysis

The laser can be concentrated by the optical system to achieve a high concentration of energy. The focused laser beam can generate a high temperature of several thousand degrees or even tens of thousands of degrees near the focal point, which will instantly vaporize or decompose the attachments on the surface of the object.

· light peeling

Through the action of the laser, the attachments on the surface of the object are heated and expanded. When the expansion force of the attachments on the surface of the object is greater than the adsorption force between it and the substrate, the attachments on the surface of the object will be detached from the surface of the object.

· light vibration

The pulsed laser with higher frequency and power is used to impact the surface of the object, and ultrasonic waves are generated on the surface of the object. The ultrasonic waves return after hitting the middle and lower hard surfaces, and interfere with the incident sound waves, thereby generating high-energy resonant waves, causing the dirt to microburst, smash, off the surface of the substrate.

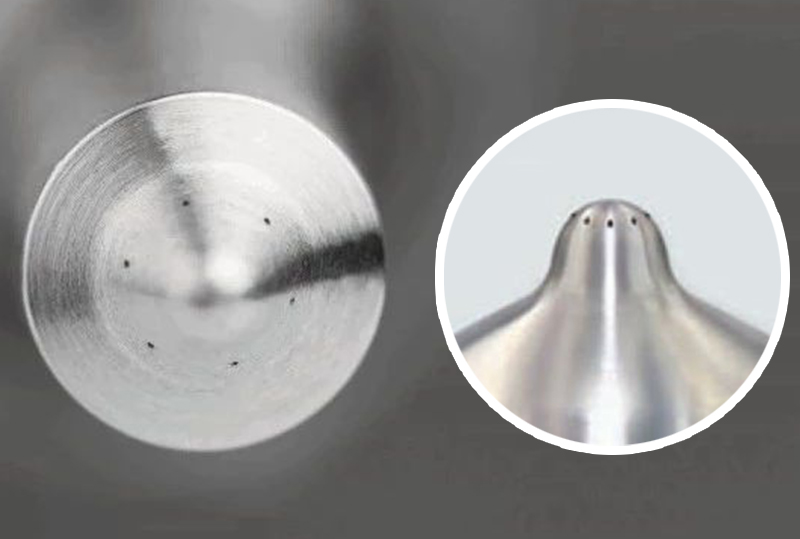

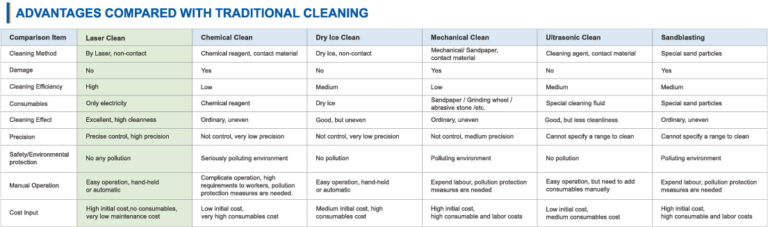

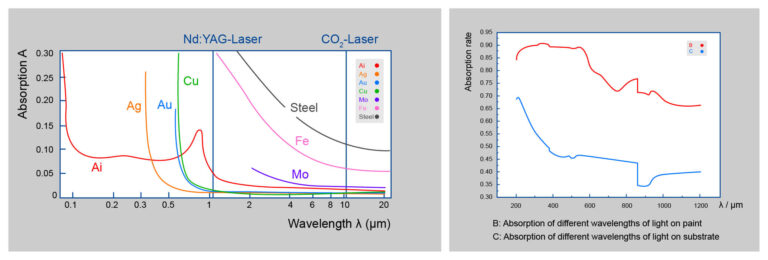

Why choose laser cleaning rather than traditional techniques?

Compared with traditional cleaning techniques (mechanical friction, sandblasting, jet, chemical), laser cleaning has the following advantages:

Environmental advantages: Laser cleaning is a “green” cleaning method that does not require the use of any chemicals and cleaning fluids, which can avoid environmental pollution problems caused by chemical cleaning.

- Effect advantage: Laser cleaning is non-abrasive and non-contact, avoiding mechanical force with the surface of the cleaned object and damaging the surface of the object. The laser cleaning parameters can be controlled to increase the corrosion resistance of metal devices by 3 to 4 times.

- Control advantage (automatic assembly line): The laser can be transmitted through optical fiber, cooperate with the robot hand and robot, can clean the parts that are difficult to reach by traditional methods (pass), can realize remote control, automation of equipment, form product assembly line operation, intelligent operation , to ensure the safety of personnel.

- Accurate positioning: use optical fiber transmission to guide the laser to make it flexible, and control the light spot to move at high speed through the built-in scanning galvanometer, which is convenient for non-contact laser on the corners such as special-shaped parts, holes, and grooves that are difficult to reach by traditional cleaning methods. cleaning process.

- Cost advantage: high efficiency of laser cleaning, long service life (up to 100,000 hours), low maintenance cost (only need to clean the lens or replace the laser regularly)

What Are the Types of Laser Cleaning?

a. Pulsed Laser Cleaning

Pulsed lasers deliver energy in short bursts (nanoseconds to microseconds) with high peak power, allowing precise control over thermal input. This is ideal for delicate or high-value surfaces.

Applications:

• Paint and coating removal

• Precision mold cleaning

• Electronics and aerospace components

b. Continuous Wave (CW) Laser Cleaning

CW lasers emit a constant beam at stable power, suitable for large-area or heavy-duty tasks.

Applications:

• Rust removal on steel structures

• Pre-welding surface preparation

• Shipbuilding and heavy machinery

Choosing between pulsed and CW depends on contamination type, material sensitivity, surface area, and required throughput.

What factors will affect the laser cleaning effect?

Laser cleaning method, cleaning model, laser type, laser wavelength, energy density, power, pulse frequency, pulse time and laser incidence angle and other process parameters will have a certain impact on the cleaning effect.

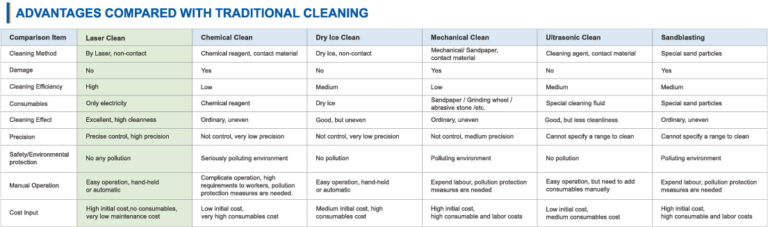

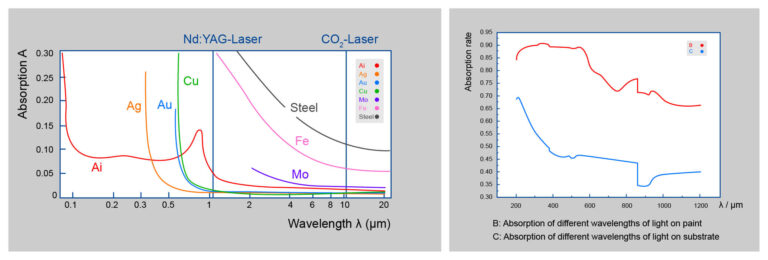

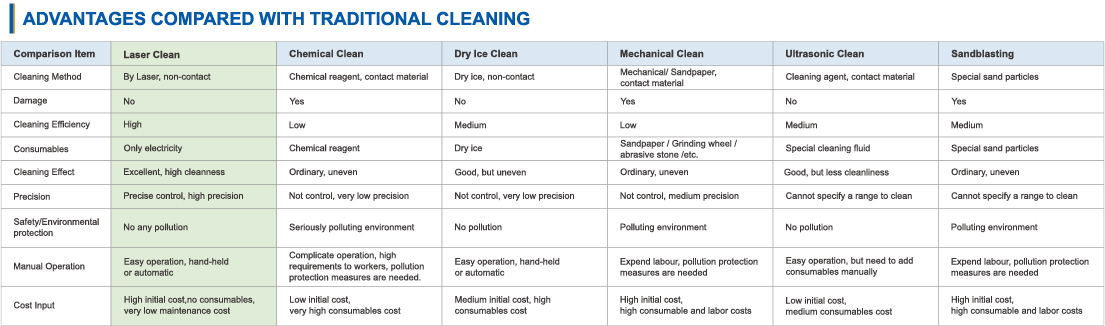

1) Laser type and wavelength

As shown in the figure, when λ=916nm~1200nm, most metals have higher absorption coefficients in this band, and organics have relatively strong laser absorption in this band. Therefore, fiber lasers have unique advantages for the processing of metal materials.

2) Laser incident angle

When the laser is incident at a certain oblique angle, the laser is directly radiated under the adhering particles, resulting in higher thermoelastic stress, and the contaminants are easier to remove compared with normal incidence.

What Are the Key Components of a Laser Cleaning System?

A high-performance laser cleaning system requires coordinated components for efficiency, stability, and precision.

a. Laser Source

The laser source is the core of any system. Fiber lasers dominate industrial laser cleaning due to high efficiency, reliability, compact design, and long lifespan.

Standard Fiber Lasers vs. MOPA Fiber Lasers:

• Standard fiber lasers: Fixed pulse characteristics, suitable for heavy rust removal, pre-welding cleaning, and large-area cleaning.

• MOPA fiber lasers: Adjustable pulse width, frequency, and peak power. Ideal for delicate surfaces requiring precise control.

MOPA advantages:

• Optimize energy absorption by the contaminant layer

• Reduce thermal impact on the substrate

• Improve selectivity between coating and base material

• Consistent results on sensitive components

Selection factors:

• Average power requirements

• Pulse or continuous mode

• Degree of pulse control needed

• Material type and contamination characteristics

• Production speed and repeatability

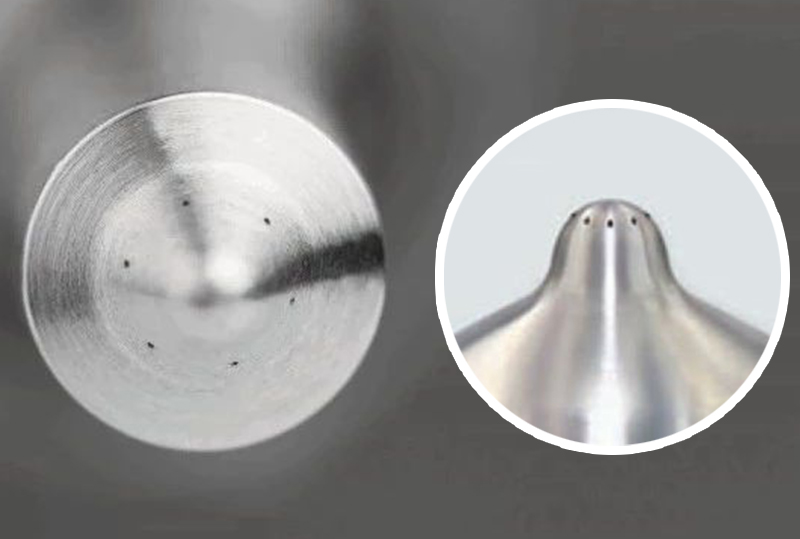

b. Laser Cleaning Galvo Head

The scanner head, usually galvanometer-based, controls beam movement across the surface. Its performance determines:

• Cleaning uniformity

• Processing speed

• Spot positioning accuracy

High-quality scanner heads ensure precise scanning, especially for high-speed or automated applications.

c. Optical System

The optical system includes F-theta lenses, protective windows, and beam expanders. It shapes and focuses the laser beam while protecting components from debris. Optical quality affects:

• Spot size and energy distribution

• Focal accuracy

• System lifespan

d. Control System and Software

Modern laser cleaning relies on intelligent control systems for:

• Storing cleaning recipes

• Optimizing scanning patterns

• Managing energy density

• Monitoring real-time process stability

• Integrating with automated production lines

Common Questions About Laser Cleaning

Will it damage the substrate?

Properly set parameters make laser cleaning safe for most materials.

Are consumables required?

No, laser cleaning does not require abrasives or chemicals.

Is it safe for operators?

With proper enclosures and safety standards, laser cleaning is safe for industrial use.

Application of Laser Cleaning

Laser cleaning rust removal

- What is laser cleaning/laser ablation?

- How does laser cleaning rust removal work?

- Why choose laser cleaning rather than traditional techniques?

- What are the types of laser cleaning?

- What factors will affect the laser cleaning effect?

- What are the key components of a laser cleaning systems?

- Common questions about laser cleaning?

- Application of Laser Cleaning

What is laser cleaning/laser ablation?

Laser cleaning (also known as laser ablation), refers to the use of high-frequency and high-energy laser beams to irradiate the surface of the workpiece to instantly evaporate or peel off oil, rust or coatings on the surface, thereby achieving a clean laser process.

How does laser cleaning rust removal work?

Laser cleaning is to use the characteristics of high laser intensity, high energy density, strong focusing and good directionality to focus the beam to a small area, and use the vibration of the laser pulse, thermal expansion, and molecular photolysis., to overcome the binding force between the dirt and the surface of the substrate, so that the dirt can be separated from the surface to achieve the purpose of cleaning.

· Photolysis

The laser can be concentrated by the optical system to achieve a high concentration of energy. The focused laser beam can generate a high temperature of several thousand degrees or even tens of thousands of degrees near the focal point, which will instantly vaporize or decompose the attachments on the surface of the object.

· light peeling

Through the action of the laser, the attachments on the surface of the object are heated and expanded. When the expansion force of the attachments on the surface of the object is greater than the adsorption force between it and the substrate, the attachments on the surface of the object will be detached from the surface of the object.

· light vibration

The pulsed laser with higher frequency and power is used to impact the surface of the object, and ultrasonic waves are generated on the surface of the object. The ultrasonic waves return after hitting the middle and lower hard surfaces, and interfere with the incident sound waves, thereby generating high-energy resonant waves, causing the dirt to microburst, smash, off the surface of the substrate.

Why choose laser cleaning rather than traditional techniques?

Compared with traditional cleaning techniques (mechanical friction, sandblasting, jet, chemical), laser cleaning has the following advantages:

Environmental advantages: Laser cleaning is a “green” cleaning method that does not require the use of any chemicals and cleaning fluids, which can avoid environmental pollution problems caused by chemical cleaning.

- Effect advantage: Laser cleaning is non-abrasive and non-contact, avoiding mechanical force with the surface of the cleaned object and damaging the surface of the object. The laser cleaning parameters can be controlled to increase the corrosion resistance of metal devices by 3 to 4 times.

- Control advantage (automatic assembly line): The laser can be transmitted through optical fiber, cooperate with the robot hand and robot, can clean the parts that are difficult to reach by traditional methods (pass), can realize remote control, automation of equipment, form product assembly line operation, intelligent operation , to ensure the safety of personnel.

- Accurate positioning: use optical fiber transmission to guide the laser to make it flexible, and control the light spot to move at high speed through the built-in scanning galvanometer, which is convenient for non-contact laser on the corners such as special-shaped parts, holes, and grooves that are difficult to reach by traditional cleaning methods. cleaning process.

- Cost advantage: high efficiency of laser cleaning, long service life (up to 100,000 hours), low maintenance cost (only need to clean the lens or replace the laser regularly)

What Are the Types of Laser Cleaning?

a. Pulsed Laser Cleaning

Pulsed lasers deliver energy in short bursts (nanoseconds to microseconds) with high peak power, allowing precise control over thermal input. This is ideal for delicate or high-value surfaces.

Applications:

• Paint and coating removal

• Precision mold cleaning

• Electronics and aerospace components

b. Continuous Wave (CW) Laser Cleaning

CW lasers emit a constant beam at stable power, suitable for large-area or heavy-duty tasks.

Applications:

• Rust removal on steel structures

• Pre-welding surface preparation

• Shipbuilding and heavy machinery

Choosing between pulsed and CW depends on contamination type, material sensitivity, surface area, and required throughput.

What factors will affect the laser cleaning effect?

Laser cleaning method, cleaning model, laser type, laser wavelength, energy density, power, pulse frequency, pulse time and laser incidence angle and other process parameters will have a certain impact on the cleaning effect.

1) Laser type and wavelength

As shown in the figure, when λ=916nm~1200nm, most metals have higher absorption coefficients in this band, and organics have relatively strong laser absorption in this band. Therefore, fiber lasers have unique advantages for the processing of metal materials.

2) Laser incident angle

When the laser is incident at a certain oblique angle, the laser is directly radiated under the adhering particles, resulting in higher thermoelastic stress, and the contaminants are easier to remove compared with normal incidence.

A high-performance laser cleaning system requires coordinated components for efficiency, stability, and precision.

a. Laser Source

The laser source is the core of any system. Fiber lasers dominate industrial laser cleaning due to high efficiency, reliability, compact design, and long lifespan.

Standard Fiber Lasers vs. MOPA Fiber Lasers:

• Standard fiber lasers: Fixed pulse characteristics, suitable for heavy rust removal, pre-welding cleaning, and large-area cleaning.

• MOPA fiber lasers: Adjustable pulse width, frequency, and peak power. Ideal for delicate surfaces requiring precise control.

MOPA advantages:

• Optimize energy absorption by the contaminant layer

• Reduce thermal impact on the substrate

• Improve selectivity between coating and base material

• Consistent results on sensitive components

Selection factors:

• Average power requirements

• Pulse or continuous mode

• Degree of pulse control needed

• Material type and contamination characteristics

• Production speed and repeatability

b. Laser Cleaning Galvo Head

The scanner head, usually galvanometer-based, controls beam movement across the surface. Its performance determines:

• Cleaning uniformity

• Processing speed

• Spot positioning accuracy

High-quality scanner heads ensure precise scanning, especially for high-speed or automated applications.

c. Optical System

The optical system includes F-theta lenses, protective windows, and beam expanders. It shapes and focuses the laser beam while protecting components from debris. Optical quality affects:

• Spot size and energy distribution

• Focal accuracy

• System lifespan

d. Control System and Software

Modern laser cleaning relies on intelligent control systems for:

• Storing cleaning recipes

• Optimizing scanning patterns

• Managing energy density

• Monitoring real-time process stability

• Integrating with automated production lines

Common Questions About Laser Cleaning

Will it damage the substrate?

Properly set parameters make laser cleaning safe for most materials.

Are consumables required?

No, laser cleaning does not require abrasives or chemicals.

Is it safe for operators?

With proper enclosures and safety standards, laser cleaning is safe for industrial use.