In today’s rapidly advancing technological landscape, fiber lasers have become essential tools across industrial manufacturing, research laboratories, and medical applications. With their high efficiency, exceptional beam quality, and reliable performance, fiber lasers offer precision and versatility that traditional laser sources cannot match. Sino-Galvo, as a specialized manufacturer, focuses on delivering high-quality 20W and 30W fiber lasers, meeting the needs of mid-power laser processing, scientific research, and precision medical applications. This guide explores fiber laser principles, applications, and tips for selecting the right system.

What is a Fiber Laser?

A fiber laser is a laser system that uses an optical fiber as the gain medium. The fiber’s core, typically doped with rare-earth elements such as ytterbium (Yb³⁺) or erbium (Er³⁺), enables efficient light amplification. Key advantages include:

- High electrical-to-optical efficiency: Fiber lasers convert electrical power into laser output with minimal loss, reducing energy consumption compared to conventional lasers.

- Excellent beam quality: Single-mode or multi-mode output (M² close to 1) enables fine, high-precision processing.

- Compact and low-maintenance design: Fiber-based construction reduces alignment requirements, lowering maintenance needs while increasing system reliability.

- Environmental stability: Fiber lasers can operate under vibration, temperature variations, and other challenging conditions.

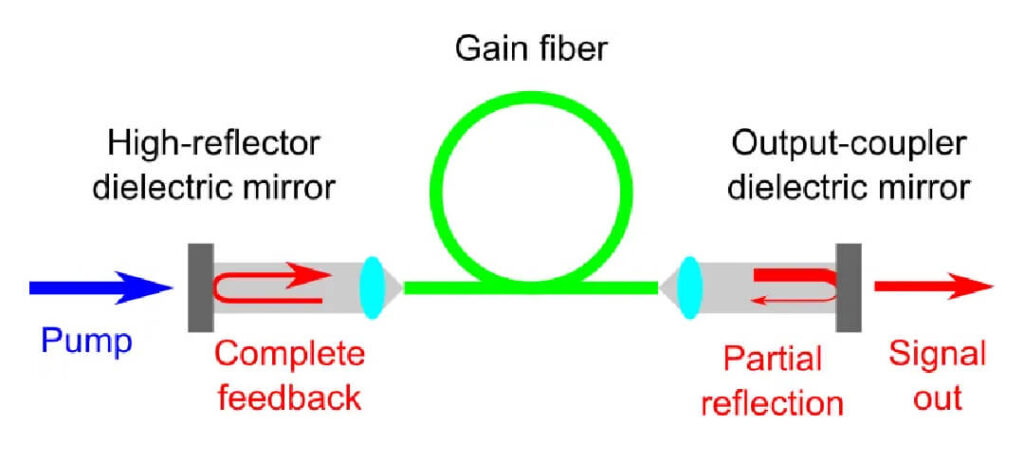

How Fiber Lasers Work

The operation of a fiber laser relies on the interaction between pump light and the doped fiber medium, through the following steps:

- Pump light injection

Semiconductor or other pump sources emit light, which is coupled into the doped fiber. The pump excites ions to higher energy levels, storing energy for laser emission. - Population inversion

Excited ions accumulate in a higher energy state, creating population inversion—a prerequisite for stimulated emission. - Stimulated emission and light amplification

High-energy ions release photons when stimulated, matching the pump light’s frequency. These photons reflect and amplify along the fiber, forming a stable, high-brightness laser beam. - Waveguide effect preserves beam quality

The fiber’s core-cladding structure confines light, maintaining directionality and uniformity for precision processing and long-distance transmission.

Applications of 20W and 30W Fiber Lasers

Thanks to their stability, precision, and compact size, 20W and 30W fiber lasers are widely used in multiple fields:

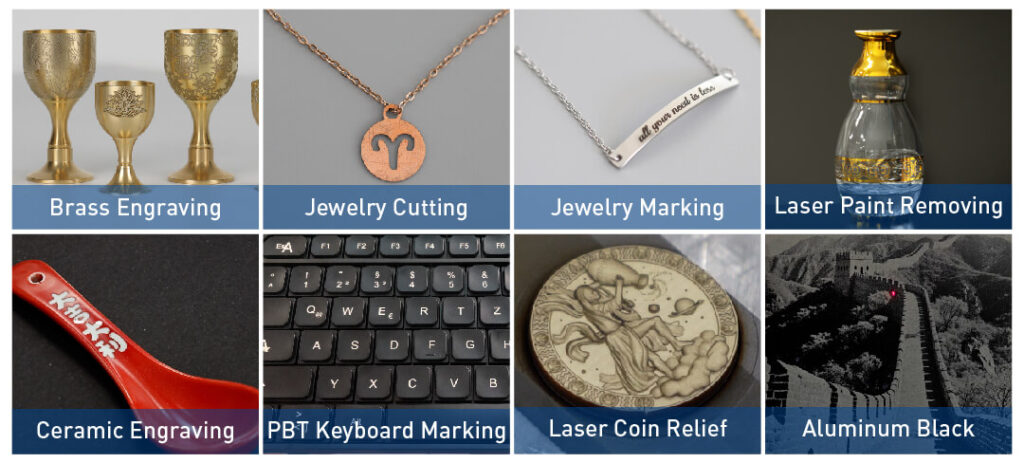

- Industrial Manufacturing

- Laser marking: High-precision marking on metals, plastics, and ceramics, with line widths down to 0.01 mm for microstructures and QR codes.

- Laser welding: Ideal for thin metal sheets like stainless steel, copper, and aluminum. Produces fine welds with minimal heat-affected zones, suitable for electronics and precision instruments.

- Laser cutting and engraving: Achieves clean edges on plastics, acrylic, and thin metals without secondary processing.

- Scientific Research

- Nonlinear optics experiments: Single-mode output supports frequency conversion, ultrafast pulse generation, and advanced photonics research.

- Material science: Used for precision modification, thin film processing, and microstructure fabrication, providing repeatable, adjustable laser sources.

- Medical Technology

- Minimally invasive procedures: Precise beams from 20W–30W lasers enable eye surgery, dermatology treatments, and microvascular interventions, reducing tissue damage and recovery time.

- Medical device processing: High-precision marking and micro-welding of medical instruments enhance quality and traceability.

How to Choose the Right Fiber Laser

Selecting a fiber laser depends on several factors:

- Power level: 20W–30W lasers are suitable for precision tasks and mid-power applications. Higher power is necessary for thicker materials or higher-speed processing.

- Beam quality: Ensure M² values meet precision requirements for marking, cutting, or research experiments.

- Cooling and stability: Check whether the system provides active cooling for consistent performance.

- Integration and customization: Consider features like red-light preview, adjustable pulse width, and high-speed modulation, depending on application needs.

- Support and maintenance: Reliable after-sales service is critical, especially for long-term research or industrial use.

Sino-Galvo Fiber Laser Advantages

As a leading fiber laser manufacturer, Sino-Galvo offers distinct advantages:

- High-quality materials and precision components

Using internationally sourced high-purity fibers and pump devices, our lasers achieve stable operation and long lifetimes. - Customizable solutions

Optional features like red-light preview, pulse width tuning, and fast modulation provide flexibility for research, industrial, and medical applications. - In-house technical expertise

Proprietary technology and a skilled R&D team enable innovations in beam quality, power stability, and intelligent system features. - Strict quality control

ISO9001-compliant processes ensure each unit undergoes comprehensive testing for power, beam quality, and thermal stability, guaranteeing reliable performance.

Conclusion

Fiber lasers, particularly 20W and 30W models, are indispensable tools for modern industry, scientific research, and medical applications. Understanding fiber laser principles, operational mechanisms, and selection criteria helps buyers make informed decisions. Sino-Galvo’s expertise in manufacturing high-quality fiber lasers ensures that customers receive systems that combine precision, reliability, and versatility for diverse applications.