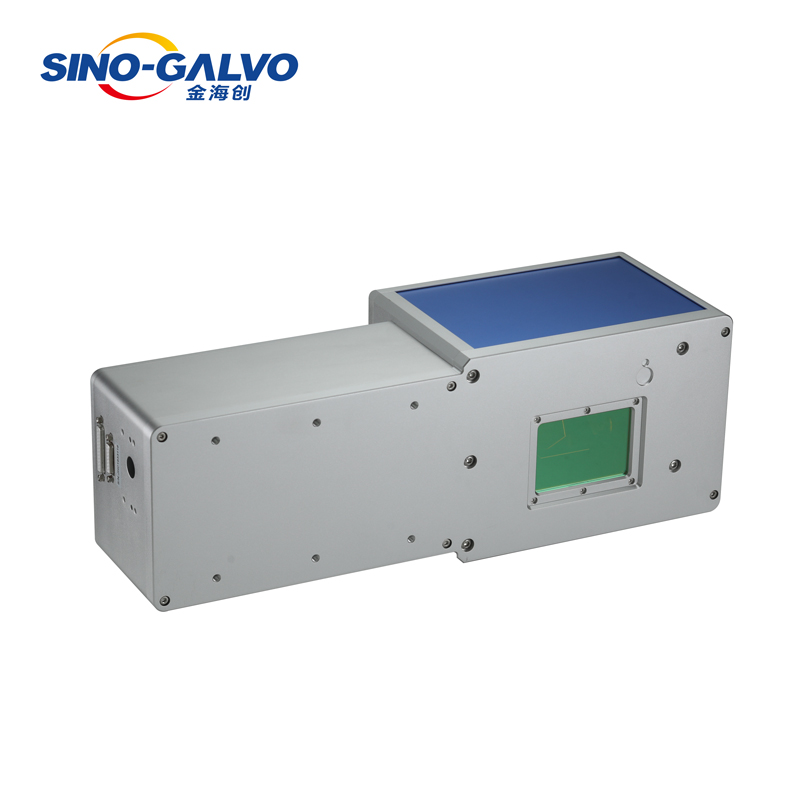

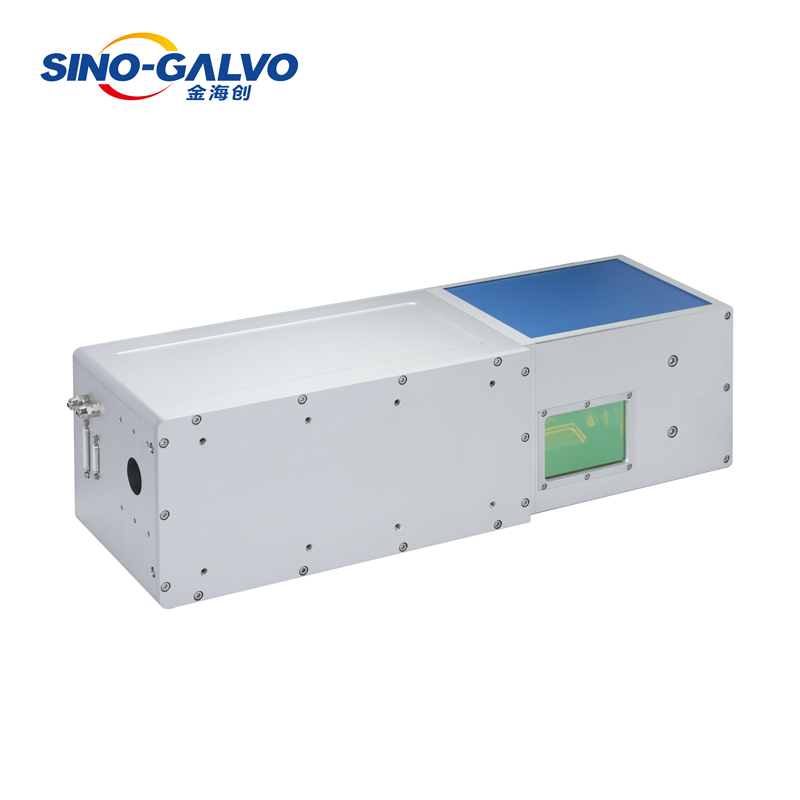

FL8330-3D Fiber 3D Galvo scanning system (600*600-700*700mm)

- Suitable for processing on metal for laser marking, cutting, welding, drilling, laser micro-machining, 3D applications, laser rapid prototyping and etc.

- Water cooling structure to effectively control the working temperature.

FL8330-3D Fiber 3D Galvo scanning system (600*600-700*700mm)

- Suitable for processing on metal for laser marking, cutting, welding, drilling, laser micro-machining, 3D applications, laser rapid prototyping and etc.

- Water cooling structure to effectively control the working temperature.

Product Features

Technical Parameters

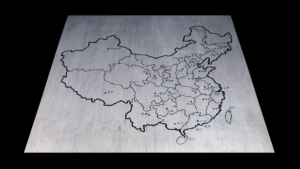

Application Shows

Product Features

- High-speed system, meets precision filling at 1500mm/s

- Maximum scan field up to 700x700mm, meets large scan field engraving requirements, according to customer requirement 600x600mm is optional.

- Maximum marking height up to 80mm to meet customer’s demand for large gap.

- Precisely control the focal length position of laser marking machine, automatically adjust Z-axis for 3D deep marking process, keep the spot size to minimum, ensure the uniform graphic effect after marking on the object.

- Adopted MM3D/Marking Mate software system to support various file formats, vector, bitmap and text bar code import, which is easy to learn and operate.

- Built-in concave and convex circular tube, concave and convex sphere, slope, cone, polygon, and other basic models, the operator can easily and rapidly set the marking.

- 3D models can be imported; 2D graphics can be directly cladded or projected on a built-in curve surface.

- The whole system adopted the optimization design of electromagnetic compatibility, with a high signal-to-noise ratio and strong anti-interference ability.

Technical Parameters

| Laser Type | 1064nm fiber laser source |

| Printing Field | 600×600mm~700×700mm |

| Input Beam Size | 7.5mm |

| X&Y Axes Mirrors Aperture Size | 30mm |

| Precision and Error | |

| Linearity | 99.90% |

| Repeatability (RMS) | <8μRad |

| Gain Error | <5mRad |

| Zero Offset | <5mRad |

| Long-term Drift Over 8 Hours | <0.5mRad |

| Scale Drift | <40PPM/℃ |

| Zero Drift | <15μRad/℃ |

| Water-Cooling System | |

| Water Temperature | 25±3℃ |

| Maximum Water Pressure | <3bar |

| Water Flow | >1L/min |

| Water Pipe Specification | Outer diameter φ6mm Inner diameter φ4mm |

| Power and Signal | |

| Input Voltage | ±24VDC |

| Rated Current | 4A |

| Interface Signal | Digital: XY2-100 |

| Machinery Scan Angle | ±11° |

| Working Current, Temperature, Dimension | |

| Working Temperature | 0℃~45℃ |

| Storage Temperature | -10℃~60℃ |

| Galvanometer Scanner Dimension | 460X160X176mm (LxWxH) |

| Galvanometer Scanner Weight | ≈11.76Kg |

| Examples of Field Size, Working Distance, Spot Size and Depth Configurations | ||

| Field Size | 600 X600mm | 700 X700mm |

| Working Distance | 790mm | 860mm |

| Spot Size | 36μm | 40μm |

| Depth | -70~0 | -70~0 |

Application Shows