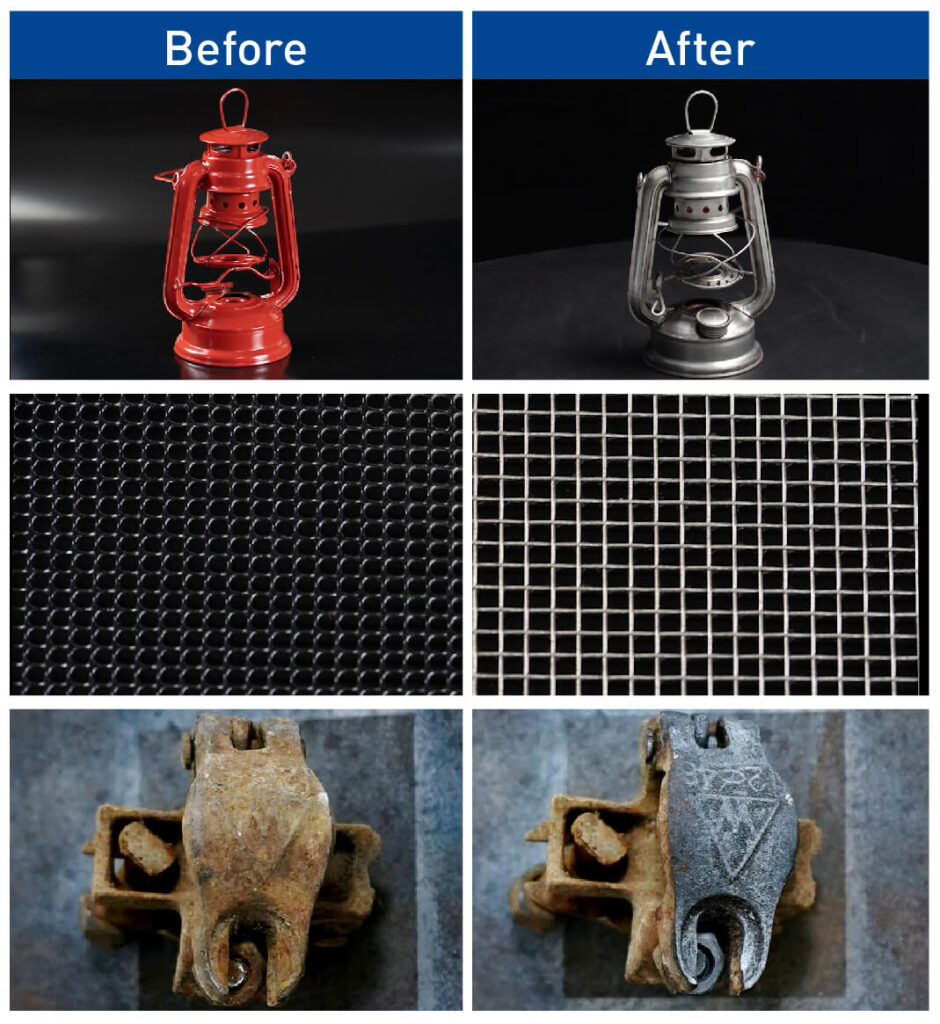

Laser cleaning technology has become an increasingly popular solution for surface treatment in industrial applications. It offers a non-contact, environmentally friendly, and highly controllable method for removing rust, paint, oxide layers, oil, and other contaminants from metal and non-metal surfaces.

However, choosing the right laser cleaning machine is not always straightforward. Terms such as pulsed vs continuous wave (CW) and single-mode vs multi-mode are often confusing for users who are new to laser cleaning. This article provides a practical, application-oriented guide to help you understand these differences and make an informed decision when selecting a laser cleaning system.

What Is Laser Cleaning and Why Machine Selection Matters

Laser cleaning is a process that uses high-energy laser beams to remove unwanted surface layers through a combination of thermal, photochemical, and mechanical effects. Unlike traditional methods such as sandblasting or chemical cleaning, laser cleaning does not require abrasives or solvents, and it allows precise control over the cleaning area.

Despite these advantages, laser cleaning is not a one-size-fits-all solution. The effectiveness of the process depends heavily on how well the machine configuration matches the application. An unsuitable selection may result in:

• Insufficient cleaning efficiency

• Damage to the base material

• Excessive heat input or surface discoloration

• Unstable or inconsistent cleaning results

Understanding the fundamental differences between laser types and beam delivery methods is therefore essential before choosing a laser cleaning machine.

Pulsed Laser Cleaning vs Continuous Wave (CW) Laser Cleaning

One of the most important decisions when selecting a laser cleaning machine is choosing between a pulsed laser and a continuous wave (CW) laser.

2.1 How Pulsed Laser Cleaning Works

A pulsed laser emits energy in extremely short bursts, typically in the nanosecond or microsecond range. Each pulse delivers a high peak power to the surface within a very short time, causing contaminants to rapidly expand and detach from the substrate.

Key characteristics of pulsed laser cleaning include:

• Very high peak power

• Minimal heat diffusion into the base material

• Excellent control over cleaning depth

• Reduced risk of thermal damage

Because of these properties, pulsed lasers are widely used in applications that require high precision and low thermal impact, such as mold cleaning, precision metal parts, electronics, and surface preparation before coating or welding.

2.2 How Continuous Wave (CW) Laser Cleaning Works

In contrast, a continuous wave laser emits a constant laser beam with stable output power. Instead of relying on high peak power, CW laser cleaning removes contaminants through sustained heating and gradual material removal.

Typical features of CW laser cleaning include:

• Constant energy output

• High average power

• High cleaning efficiency for large areas

• Greater thermal input to the surface

CW laser cleaning is often used in heavy-duty industrial applications, such as large-scale rust removal, paint stripping, or surface treatment where speed and coverage are more important than fine detail.

2.3 Pulsed vs CW Laser Cleaning: A Practical Decision Guide

Step 1: Define the Primary Objective

Choose CW laser cleaning when the priority is:

• Large-area surface cleaning

• High processing speed

• Maximum throughput in continuous production environments

Choose pulsed laser cleaning when the priority is:

• Precise process control

• Minimal heat input

• Protection of the substrate or surface integrity

Step 2: Evaluate Contaminant Thickness in Context

• For large surface areas, CW laser cleaning typically delivers higher productivity due to continuous energy output.

• For thick paint layers or heavy rust on heat-sensitive or high-value components, pulsed laser cleaning provides better control and reduced thermal risk.

Contaminant thickness should always be evaluated together with cleaning area size and substrate thermal tolerance, rather than as an isolated parameter.

Step 3: Align the Technology with Real-World Applications

In practical applications:

• Pulsed laser cleaning is widely used for molds, precision parts, and complex geometries where controlled energy delivery is critical.

• CW laser cleaning is commonly applied to large-scale industrial rust or paint removal where processing speed outweighs fine thermal control.

Key Takeaway

There is no universally “better” solution between pulsed and CW laser cleaning.

The optimal choice depends on the required cleaning area, process speed, and the thermal sensitivity of the substrate.

Single-Mode vs Multi-Mode Laser for Cleaning Applications

Another critical factor in laser cleaning machine selection is the beam mode of the laser source.

Single-Mode vs Multi-Mode

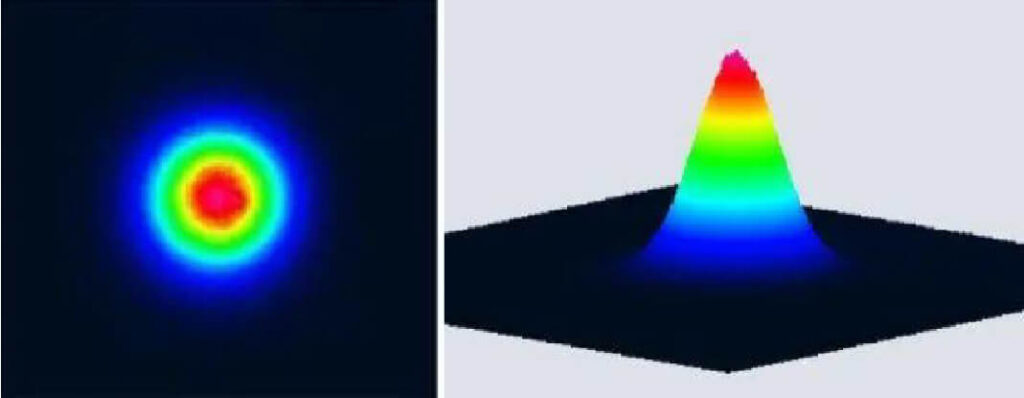

3.1 Single-Mode Laser: Precision and Energy Density

A single-mode laser produces a highly concentrated beam with excellent beam quality, typically characterized by a low M² value. This allows the laser to be focused into a very small spot, resulting in high energy density.

Advantages of single-mode lasers include:

• Small spot size

• High energy concentration

• Superior precision and controllability

• Suitable for fine and detailed cleaning

Single-mode lasers are commonly used in precision cleaning tasks where the cleaning area is small and the tolerance for thermal effects is extremely low.

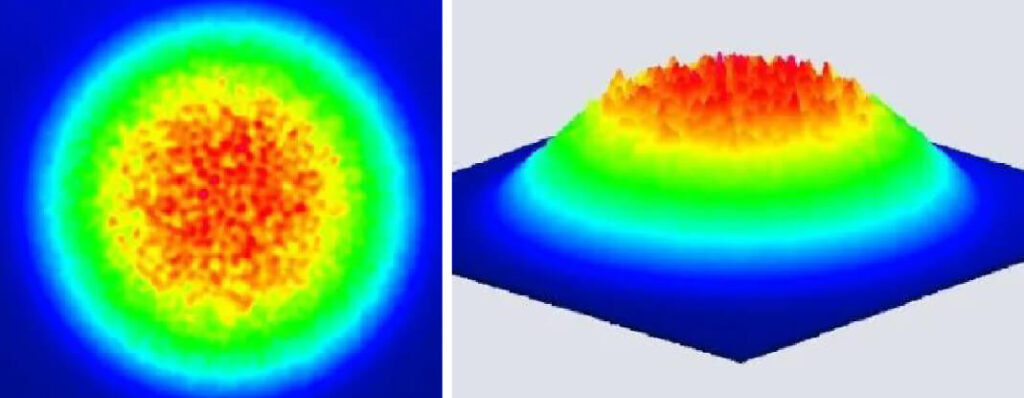

3.2 Multi-Mode Laser: Coverage and Efficiency

Multi-mode lasers emit a beam composed of multiple transverse modes, resulting in a larger spot size and lower energy density compared to single-mode lasers.

Key benefits of multi-mode lasers include:

• Larger cleaning area per pass

• Higher tolerance for surface irregularities

• Better efficiency for large-scale cleaning

• Lower system cost per watt

Multi-mode lasers are often selected for industrial rust removal, paint stripping, and other applications where coverage and throughput are more important than micrometer-level precision.

3.3 How Beam Quality Affects Cleaning Results

While beam quality plays an important role in laser cleaning performance, it is not the only determining factor. The way the laser beam is delivered and scanned across the surface also has a significant impact on cleaning uniformity, efficiency, and thermal control.

This makes the overall system design—rather than just the laser source—critical to achieving consistent cleaning results.

Key Components of a Laser Cleaning System

A laser cleaning machine is a combination of multiple subsystems working together. Understanding these components helps clarify why system-level selection is essential.

4.1 Laser Source

The laser source defines the fundamental characteristics of the cleaning process, including:

• Operating mode (pulsed or CW)

• Output power

• Wavelength (commonly 1064 nm for fiber lasers)

The laser source determines how energy interacts with the contaminant and the substrate, but it does not act alone.

4.2 Beam Delivery and Scanning System

In most modern laser cleaning machines, the laser beam is directed and controlled by a galvanometer-based scanning system, which moves the beam rapidly across the surface according to predefined patterns.

The scanning system directly affects:

• Cleaning speed

• Uniformity of energy distribution

• Edge quality and overlap control

• Heat accumulation on the surface

A well-designed [laser cleaning galvo scanner] allows precise control of scanning paths and speeds, ensuring that the laser energy is applied evenly and efficiently, especially when cleaning complex geometries or large surfaces.

4.3 Control Software and Parameters

Laser cleaning performance also depends on control card and software-level parameters such as:

• Scanning speed

• Line spacing and overlap ratio

• Pulse frequency (for pulsed lasers)

• Power modulation

These parameters must be optimized together with the laser source and scanning system to achieve stable and repeatable cleaning results.

How Scanning Performance Affects Cleaning Quality

While laser power and beam mode receive much of the attention, scanning performance is often underestimated in laser cleaning applications.

Poor scanning control can lead to:

• Uneven cleaning patterns

• Incomplete contaminant removal

• Excessive heat buildup in localized areas

• Reduced processing efficiency

A high-performance laser cleaning galvo scanner enables precise control over beam motion, allowing consistent overlap and smooth transitions between scan lines. This is particularly important when cleaning sensitive surfaces or working at high speeds, where improper scanning can quickly degrade surface quality.

By optimizing scanning accuracy and stability, manufacturers can achieve better cleaning results without increasing laser power.

Typical Laser Cleaning Applications and Recommended Configurations

Different applications require different system configurations. The table below provides general guidance for common laser cleaning scenarios.

| Application | Laser Type | Beam Mode | Scanning Requirement |

| Mold cleaning | Pulsed | Single or Multi-mode | High precision, stable scanning |

| Rust removal | Pulsed or CW | Multi-mode | High speed, wide coverage |

| Precision metal parts | Pulsed | Single-mode | Fine control, low heat input |

| Automotive components | Pulsed or CW | Multi-mode | Consistent, repeatable scanning |

| Surface pre-treatment | Pulsed | Single-mode | Uniform energy distribution |

These recommendations should be validated through sample testing, as material properties and contaminant characteristics can vary significantly.

Final Checklist: How to Choose the Right Laser Cleaning Machine

Before making a final decision, consider the following checklist:

• What is the base material (steel, aluminum, stainless steel, etc.)?

• What type of contaminant needs to be removed (rust, paint, oil, oxide)?

• How sensitive is the surface to heat?

• What level of cleaning precision is required?

• What is the size of the cleaning area?

• Is automation or integration into a production line required?

• Does the system offer stable and precise scanning control?

Answering these questions will help narrow down the most suitable laser cleaning configuration for your application.

Conclusion

Choosing a laser cleaning machine requires a clear understanding of both the application requirements and the underlying technology. The decision between pulsed and CW lasers affects thermal behavior and precision, while the choice between single-mode and multi-mode beams determines energy density and coverage.

Equally important is recognizing that laser cleaning performance depends on the entire system, including beam delivery and scanning components. By focusing on system-level optimization rather than individual specifications, users can achieve more reliable, efficient, and consistent cleaning results.

With the right configuration, laser cleaning can provide a powerful and flexible solution for a wide range of industrial surface treatment applications.