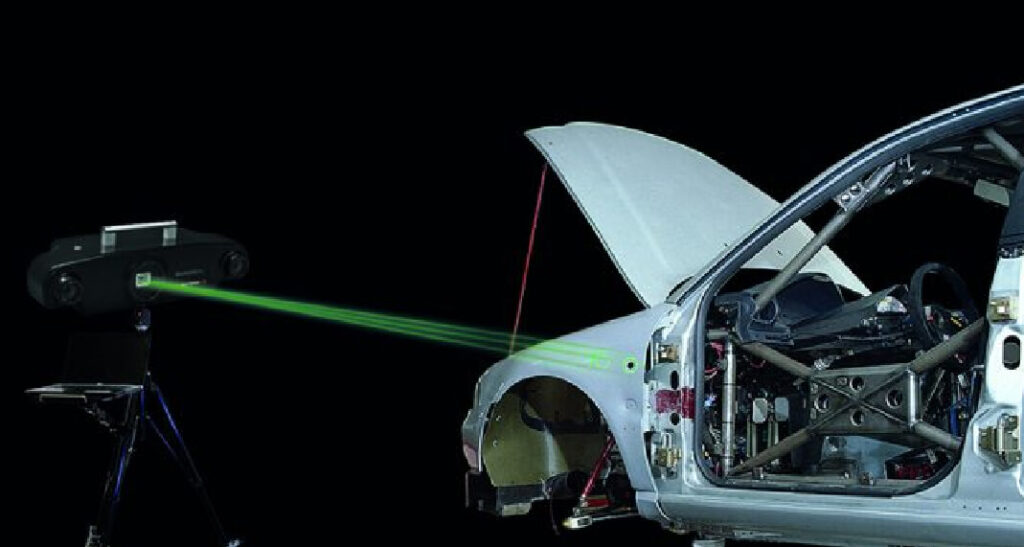

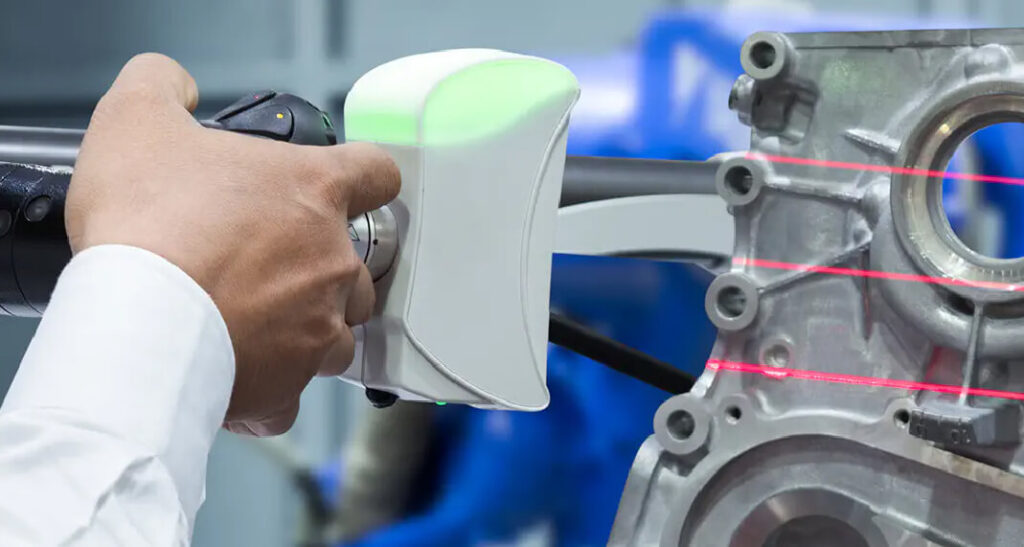

In modern industrial environments, laser projection systems are used to project lines, points, or entire contours directly onto surfaces or materials. With this innovation, the once-necessary heavy templates used for difficult-to-produce components have become obsolete, and time-consuming calibration processes are now a thing of the past. Within seconds, the precise positioning of parts on a material surface can be visualized, contours can be displayed, or position checks can be carried out. Laser projection makes production processes faster, more flexible, and significantly more ergonomic for workers. Thanks to automatic alignment capabilities, laser projection systems can quickly and accurately reach difficult areas and project shapes or reference points, such as marker positions in automotive body structures.

Working principle of laser projector

The laser projector uses a laser light source and dual-axis galvo scanners to perform high-speed optical scanning of digital models, projecting CAD drawings or coordinate data directly onto the workspace in the form of lines, points, and contours. In contrast, a conventional projector uses an LED or lamp light source together with a DLP/LCD imaging chip to generate a full image, which is then projected through a lens—making it more suitable for photos, videos, and large-area visuals. Unlike traditional projectors, a laser projector does not display an image; instead, it “draws” with laser beams. As a result, it remains clearly visible under bright ambient light, provides much higher precision, and offers longer effective projection distance, making it ideal for industrial manufacturing, composite layup, woodworking, and large-scale assembly applications.

Projection-Based AR: Enhanced Visualization for Complex Assembly

Projection-based augmented reality (AR) is emerging as a highly promising tool for industrial workflows, and it represents a natural extension of laser projection technology. The core idea is straightforward: a projection-based AR environment overlays computer-generated visual information directly onto real-world surfaces. In other words, additional digital content is merged with the physical environment through projection. As powerful projectors and advanced software systems continue to evolve, this technology will see increasing adoption in modern industry. For example, during future assembly processes, parts and individual work steps can be projected directly onto the workstation. The system could color-highlight or virtually mark the components required for the next step, and even display 3D models to show workers precisely where each part must be installed.

Application Areas of Laser Projection

Many industries are already benefiting from the growing capabilities of laser projection. As a result, 2D laser projection is being used more widely across industrial environments.

In the stone-processing industry, for instance, when cutting granite slabs, the contour to be cut is projected directly onto the surface. If the projection needs to be adjusted, the heavy stone slab does not need to be repositioned. Instead, advanced software transfers the offset directly to the saw, ensuring precise and efficient operation.

2D laser projectors are also widely used in woodworking and furniture manufacturing. They serve as positioning aids to indicate stop positions or to precisely determine the arrangement of screws, pins, or drilling points.

Beyond manufacturing, laser projection also finds use in artistic applications—such as aesthetic surface projection on art pieces—as well as in military training (flight simulation projection) and navigation systems (e.g., projected HUD information in aircraft and vehicles).

Lenses and Mirrors: The Foundation of High-Quality Laser Projection

In addition to the sophisticated software components, laser projection relies heavily on high-quality optical elements. These include specialized lenses, lens assemblies, and mirrors used for focusing, beam expansion, or beam deflection.

Aspheric lenses, for example, eliminate spherical aberration and deliver optimal imaging quality, enabling crisp and accurate projection lines. Beam-expanding optics are used to generate a suitable laser beam diameter or to optimize beam guidance over long optical distances. Laser projection systems also incorporate specialized mirror assemblies and prisms for beam deflection, often featuring a variety of advanced coatings to ensure maximum reflection performance and long-term durability.