What Is Laser Cleaning Technology?

Laser cleaning technology is an advanced surface treatment method that uses high-energy laser beams to remove unwanted contaminants from a material’s surface without physical contact. These contaminants may include rust, paint, oxide layers, oil residues, or industrial coatings.

Unlike traditional cleaning methods such as sandblasting or chemical cleaning, laser cleaning relies on precise energy control. The laser selectively interacts with the contamination layer while leaving the base material largely unaffected, making it a highly efficient and environmentally friendly solution.

Key characteristics of laser cleaning technology include:

- Non-contact and non-abrasive process

- Minimal damage to the substrate

- No chemical waste or secondary pollution

- High precision and repeatability

How Does Laser Cleaning Work?

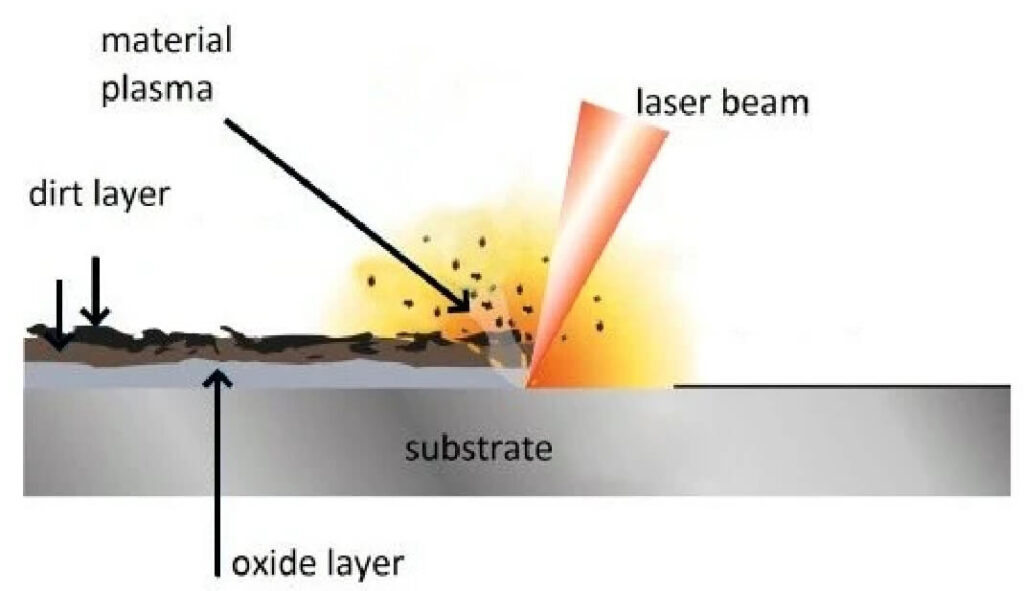

To understand laser cleaning technology, it is essential to examine how laser energy interacts with surface contaminants.

When a laser beam strikes a contaminated surface, several physical mechanisms may occur depending on laser parameters and material properties:

- Thermal ablation: The contaminant absorbs laser energy and rapidly heats up, causing evaporation or detachment.

- Plasma shock effect: High peak power lasers generate micro-plasma that breaks the adhesion between contamination and substrate.

- Photochemical effects: Short-pulse lasers can break molecular bonds without significant heat transfer.

The base material typically reflects or dissipates the laser energy differently from the contaminant layer, which allows selective removal.

Types of Laser Cleaning Technology

Laser cleaning systems are mainly categorized by laser emission mode.

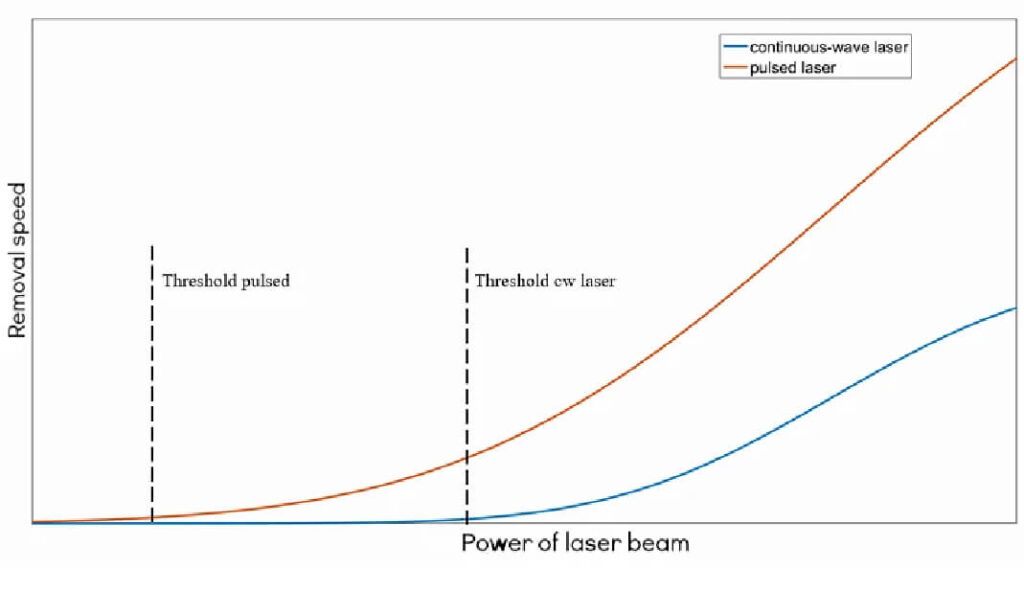

Pulsed Laser Cleaning

Pulsed laser cleaning technology delivers energy in very short bursts with high peak power. This allows precise control of thermal input and is ideal for sensitive or high-value surfaces.

Typical applications include:

- Paint and coating removal

- Precision mold cleaning

- Electronics and aerospace components

Continuous Wave (CW) Laser Cleaning

Continuous wave laser cleaning emits a constant laser beam with stable output power. It is commonly used for large-area or heavy-duty cleaning tasks.

Typical applications include:

- Rust removal on steel structures

- Pre-welding surface preparation

- Shipbuilding and heavy industry

Key Components of a Laser Cleaning System

A complete laser cleaning system consists of several critical components that directly affect cleaning efficiency, stability, and precision.

1. Laser Source

Fiber lasers and MOPA lasers are widely used in laser cleaning technology.

- Fiber lasers are known for reliability and cost efficiency.

- MOPA lasers offer adjustable pulse width and frequency, making them ideal for delicate cleaning tasks.

2.Laser Cleaning Scanner Head

The scanner head, typically based on galvanometer technology, controls beam movement across the surface.

Its performance directly impacts:

- Cleaning uniformity

- Processing speed

- Edge accuracy

High-quality scanner heads ensure stable scanning and precise spot positioning.

3.Optical System

This includes F-theta lenses, protective windows, and beam expanders. Optical quality determines focal accuracy and system lifespan.

4.Control System and Software

Modern laser cleaning systems rely on intelligent software to manage scanning patterns, energy density, and process repeatability.

Laser Cleaning Applications by Industry

Laser cleaning technology has been adopted across a wide range of industries.

Rust Removal

Efficient removal of oxidation layers without damaging the metal surface.

Paint and Coating Removal

Selective stripping without chemical solvents.

Mold Cleaning

Non-abrasive cleaning extends mold service life.

Pre-welding Surface Treatment

Improves weld quality by removing oil and oxides.

Battery and EV Manufacturing

Precision cleaning for battery tabs and housings.

Laser Cleaning vs Traditional Cleaning Methods

| Method | Surface Damage | Environmental Impact | Precision | Maintenance |

| Laser Cleaning | ⭐ | ⭐ | ⭐⭐⭐ | ⭐ |

| Sandblasting | ⭐⭐⭐ | ⭐⭐ | ⭐ | ⭐⭐⭐ |

| Chemical Cleaning | ⭐ | ⭐⭐⭐ | ⭐⭐ | ⭐⭐ |

| Mechanical Grinding | ⭐⭐⭐ | ⭐⭐ | ⭐ | ⭐⭐⭐ |

How to Choose the Right Laser Cleaning Equipment

Selecting the appropriate laser cleaning technology depends on multiple factors:

- Material type and thickness

- Type of contamination

- Required cleaning speed

- Precision requirements

- Automation level

Key decisions include:

- Pulsed vs continuous laser

- Laser power range

- Scanner head performance

- Optical durability

A well-matched system ensures consistent results and long-term cost efficiency.

Common Questions About Laser Cleaning Technology

Will laser cleaning damage the substrate?

When parameters are properly set, laser cleaning is safe for most materials.

Does laser cleaning require consumables?

No abrasive or chemical consumables are required.

Is laser cleaning safe for operators?

With proper enclosure and safety standards, laser cleaning is a safe industrial process.

Conclusion

Laser cleaning technology has become a highly effective, precise, and environmentally responsible solution for modern manufacturing. By understanding its principles, system components, and application scenarios, manufacturers can confidently select laser cleaning equipment that meets both technical and economic requirements.