Laser processing is widely used in industrial and research applications to modify the surface and structural properties of metals, polymers, and ceramics. Achieving high-quality, precise results depends heavily on selecting the correct laser parameters. This article explores how different laser parameters affect material modification, providing practical insights for engineers and researchers.

Why Laser Parameters Matter

Laser parameters directly influence how materials respond to energy input. Power, pulse duration, repetition rate, scan speed, wavelength, and focus collectively determine the quality of surface modification, structural changes, and functional performance. Understanding these parameters is essential for achieving efficient, repeatable, and controlled material processing.

Key Laser Parameters

1. Laser Power

Laser power controls the energy delivered per unit area:

• Low power → insufficient material modification

• Optimal power → precise, high-contrast marks or desired surface properties

• High power → thermal damage, melting, or cracking

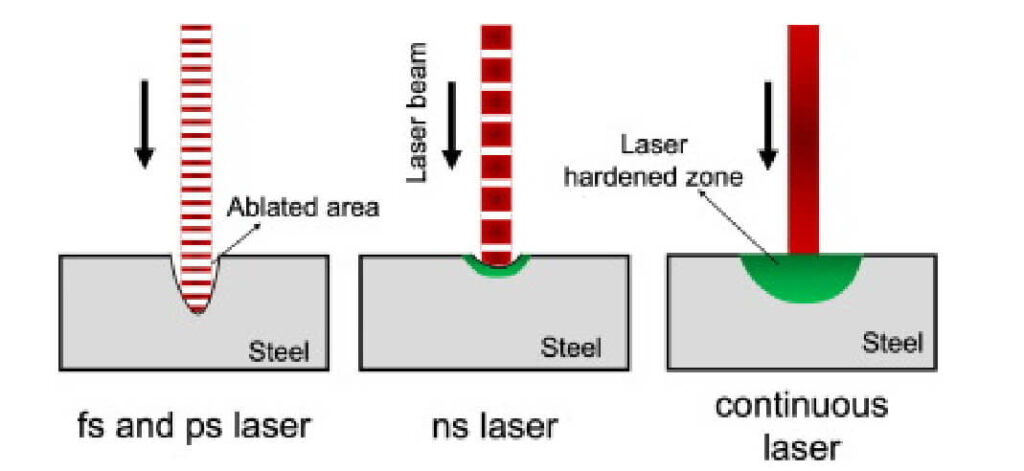

2. Pulse Duration

Pulse duration determines the laser-material interaction time:

• CW or nanosecond pulses → larger heat-affected zones

• Picosecond or femtosecond pulses → “cold” ablation, minimal thermal effects

• Short pulses → precise microstructures without melting

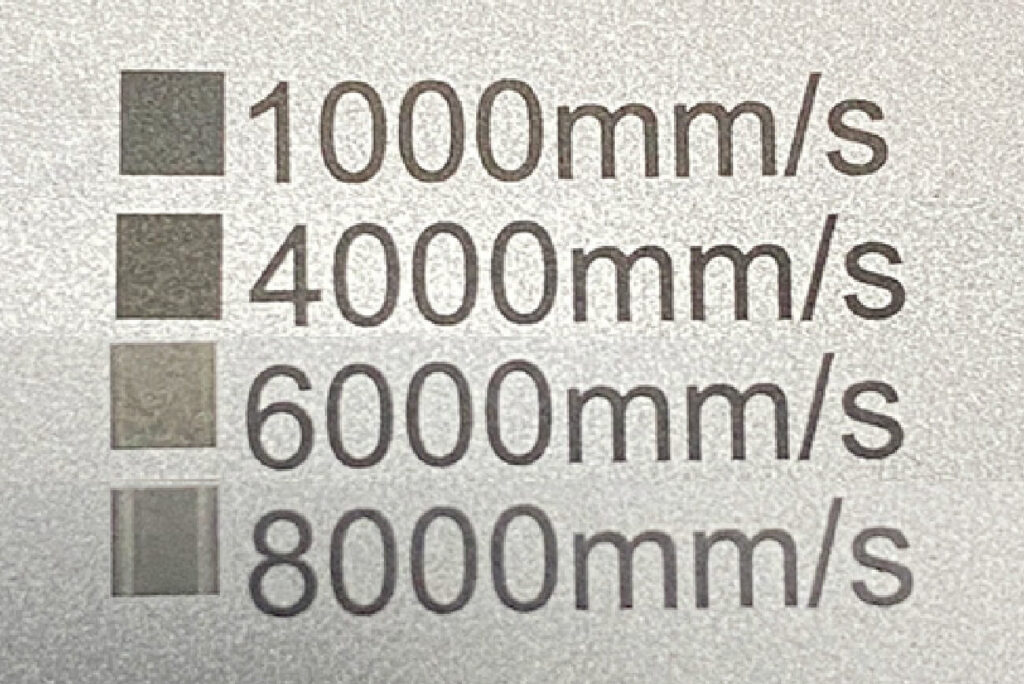

3. Repetition Rate & Scan Speed

• High repetition rate → cumulative heating, may affect surface morphology

• Low repetition rate → less heating, slower processing

• Fast scan speed → shallower markings, reduced energy per area

• Slow scan speed → deeper, more pronounced modification

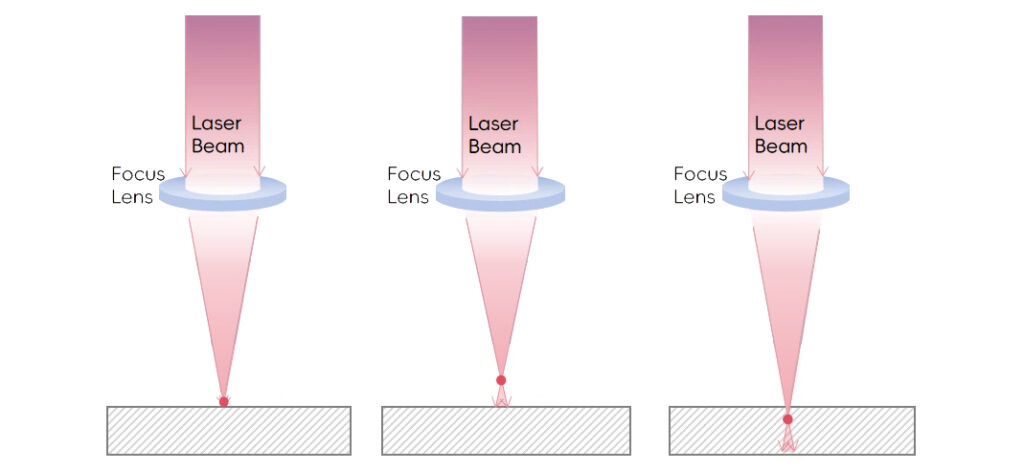

4. Wavelength & Focus

• Wavelength affects absorption efficiency: metals, polymers, and ceramics absorb differently

• Proper focus ensures sharp, well-defined markings

• Mismatch can result in blurred or inconsistent marks

Zero, Positive, and Negative Focus

Effects on Material Properties

Laser parameters influence multiple aspects of material modification:

• Surface Morphology: Smooth surfaces, microgrooves, or textured patterns depending on parameters

• Chemical Composition & Phase Change: Oxidation, alloying, or phase transformation; ultrafast lasers minimize chemical changes

• Mechanical Properties: Controlled laser treatment enhances hardness, wear resistance, and fatigue life; excessive energy may introduce cracks

• Optical & Functional Properties: Surface structuring can change reflectivity, adhesion, or wettability

Before and After Laser Marking

Practical Tips for Material Modification

• Material-Specific Optimization: Test small samples before full-scale processing

• Parameter Logging: Record optimal settings for repeatable results

• Equipment Maintenance: Clean optics, check alignment, and maintain stable environmental conditions

• Safety: Wear laser protection, ensure proper ventilation, and keep flammable materials away

Emerging Trends

• Adaptive Laser Processing: Real-time monitoring adjusts parameters dynamically for uniform results

• Femtosecond / Ultrafast Laser Applications: Expanding use in electronics, medical devices, and high-precision optics due to minimal thermal effects

• Data-Driven Optimization: Machine learning predicts optimal parameters for new materials or complex geometries

Conclusion

Selecting appropriate laser parameters is essential for effective material modification. By optimizing power, pulse duration, repetition rate, scan speed, wavelength, and focus, engineers can achieve precise surface structures, improved mechanical properties, and enhanced functional performance. Following practical tips and leveraging emerging technologies ensures consistent, high-quality results across a range of materials and applications.