Laser cleaning technology has become a new favorite in the cleaning field with its environmentally friendly, efficient and non-contact characteristics. Among them, single-mode and multi-mode in fiber pulse lasers are the two most commonly used laser types. This article aims to compare and analyze the differences between multi-mode and single-mode lasers in terms of performance, application and technical characteristics. By explaining the basic principles and key characteristics of the two, this article reveals the advantages of single-mode lasers in beam quality and stability, and the advantages of multi-mode lasers in output power and cost-effectiveness. At the same time, this article also explores the applicability and potential challenges of the two in different application scenarios to help readers make appropriate choices in practical applications.

What are multi-mode and single mode laser?

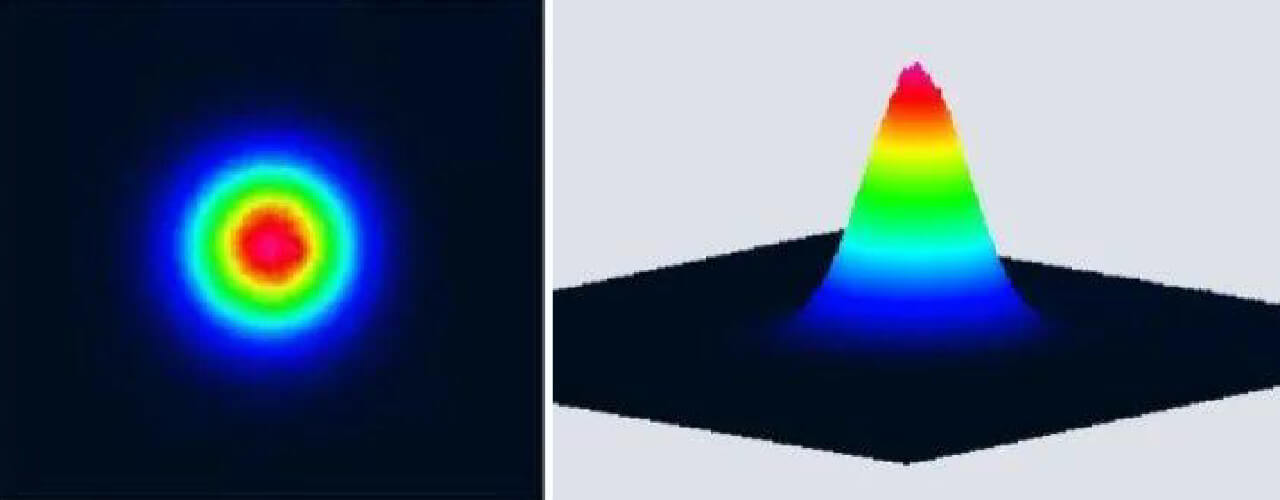

The mode of a laser usually refers to the energy distribution state in a plane perpendicular to the propagation direction of the laser, and can be divided into single-mode and multi-mode. The single-mode commonly referred to in industry refers to the transverse mode of the laser, that is, there is only one mode in the cross section, which is Gaussian distributed, and the laser energy density gradually decreases from the center to the outer edge. The laser beam output by a single mode has the characteristics of high beam quality, small beam diameter, small divergence angle, and energy distribution close to the ideal Gaussian curve. In addition, the single mode has better focusing characteristics, a small focusing spot and strong mode stability, which is suitable for cleaning scenarios that require strong removal, such as rust.

Figure 1:Schematic diagram of single-mode energy distribution

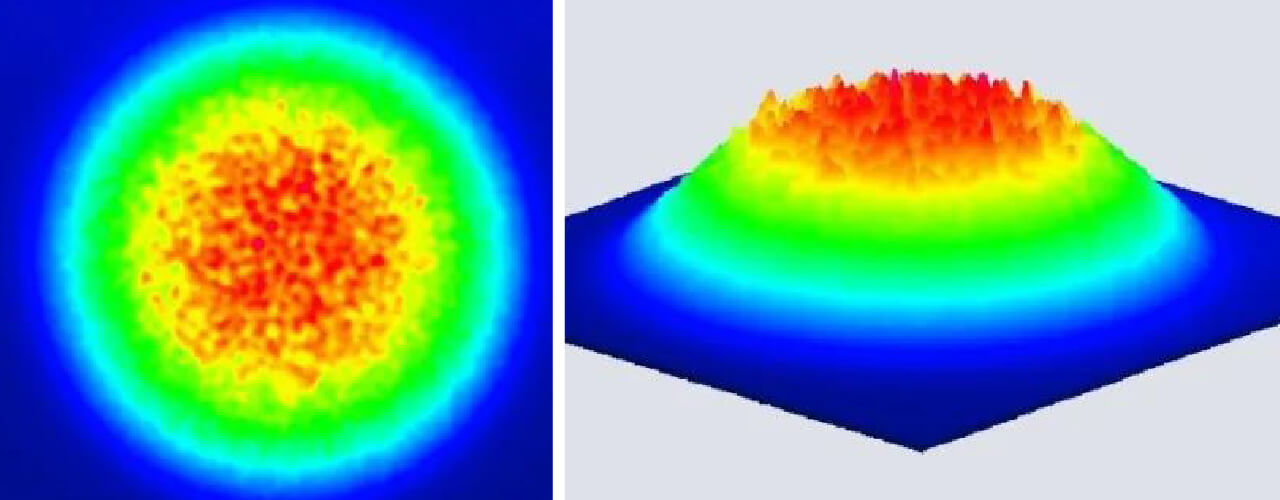

Multimode lasers are spatial energy distribution modes formed by the superposition of multiple distribution modes. The energy distribution in the spot is relatively uniform, and the more modes there are, the more uniform the energy distribution is. Its beam is also called a flat-top beam. Compared with single-mode, multimode lasers have poorer beam quality and a larger divergence angle. They require an optical system with a larger aperture for transmission, and the focused spot is larger than that of single-mode. However, multimode is easier to achieve large single pulse energy, high peak power, and high average power output, and the energy distribution is uniform, which is more advantageous for cleaning scenarios that require less damage and high efficiency, such as molds.

Figure 2:Schematic diagram of multi-mode energy distribution

What are the advantages and disadvantages of multi mode and single mode laser cleaning?

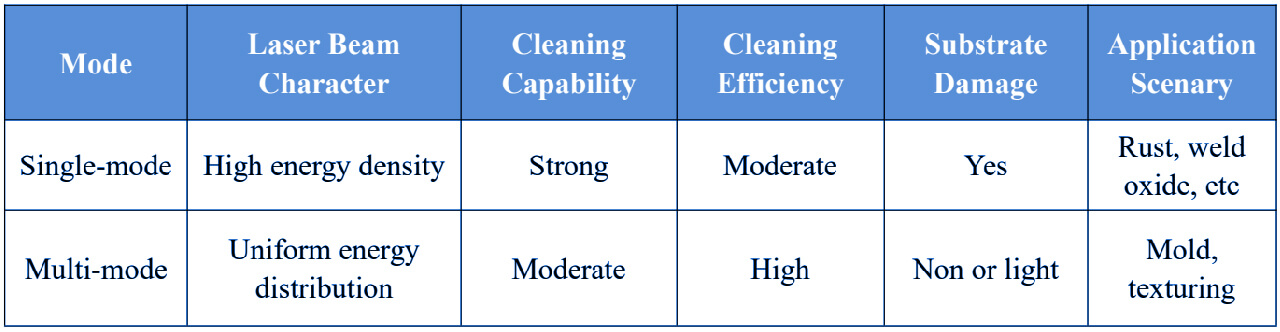

With its good beam quality, small focused spot, and high energy density, single-mode lasers are particularly suitable for cleaning contaminants with strong adhesion (such as green rust), as well as cleaning thin materials and precision parts that are sensitive to heat input. This type of laser has concentrated energy and significant cleaning effect, but may cause a certain degree of damage to the base material, especially under high energy input conditions.

Multi-mode lasers are suitable for applications that require no damage to the substrate after cleaning, such as mold cleaning. The energy distribution of the multi-mode beam is relatively uniform and the peak power is high. The peak power density can be precisely controlled to exceed the damage threshold of contaminants but lower than the damage threshold of the substrate, thereby effectively removing contaminants without damaging the material surface. At the same time, multi-mode lasers have larger focused spots and generally have higher cleaning efficiency. However, for strongly adherent contaminants, multimode laser cleaning may not be as effective as single-mode lasers.

Figure 3:Comparison of single-mode and multi-mode cleaning capabilities

Application scenarios of multi-mode and single mode lasers

Based on the respective advantages and disadvantages of single-mode and multi-mode cleaning lasers, the application scenarios in which they are applicable are also differentBased on the respective advantages and disadvantages of single-mode and multi-mode cleaning lasers, their applicable application scenarios are also different.

Single mode laser main application

- Metal rust removal: single-mode laser has high energy density and precise focusing ability, which is very suitable for metal rust removal. Its concentrated energy effectively breaks through the rust layer, making it an ideal choice for industrial rust removal. In particular, high-power lasers can significantly improve cleaning efficiency and capabilities, and are suitable for efficiently removing rust from metal surfaces.

Figure 4:Metal rust removal

- Weld oxide cleaning: During the welding process, due to the high temperature, oxides and impurities are easily formed in and around the weld, affecting the welding quality and appearance. Single-mode lasers (such as 200-500W) are suitable for precise removal of oxides on welds, ensuring post-weld surface quality and beauty without damaging the surrounding area.

Figure 5:Weld oxide cleaning

- Precision parts cleaning: For heat-sensitive materials, single-mode lasers (100-200W) have the advantages of low heat input and reduced thermal deformation, making them very suitable for precision parts cleaning. These applications include small parts in electronic components, automobiles or medical devices, which require the integrity of the material to be maintained after cleaning.

Figure 6:Precision parts cleaning

Main application of multi-mode laser

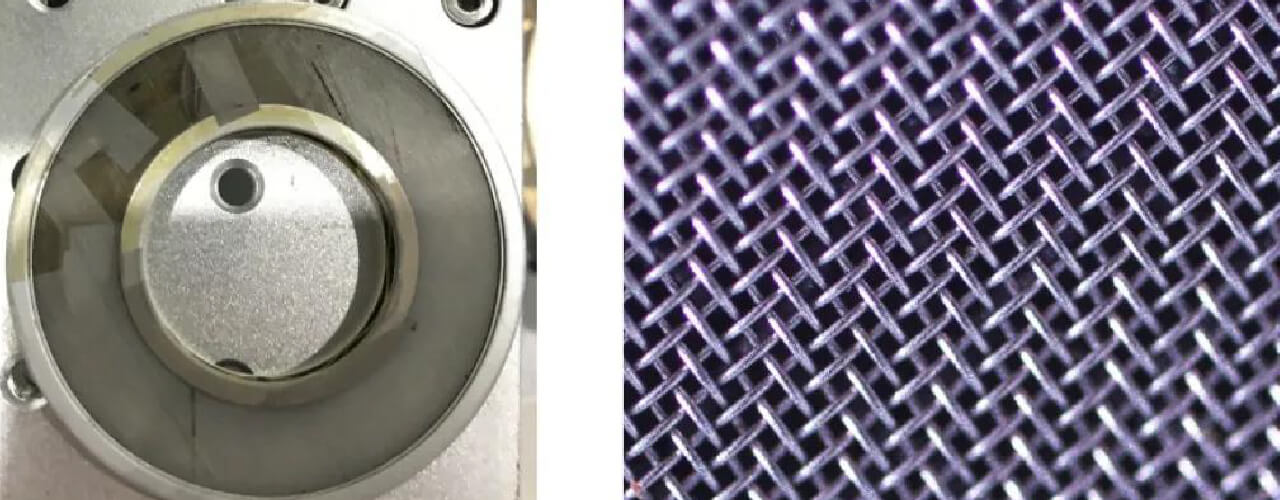

- Mold cleaning: Multimode lasers are widely used in mold maintenance. Residues such as metal fragments and dust are easily accumulated in the mold, affecting product quality. The uniform energy distribution of multimode lasers ensures effective removal of contaminants while avoiding damage to the mold substrate. Usually, a 500-1000W large spot multimode laser is selected, which combines cleaning efficiency and surface protection.

Figure 7:Mode cleaning

- Perovskite cell edge cleaning: In the production of thin-film solar cells, multimode lasers are used to clean the thin film layer at the edge and create an insulating area for packaging. The square spot output of the multimode laser ensures uniform energy distribution and can remove the thin film layer in one go without damaging the glass, making it an ideal choice for thin film cleaning.

Figure 8:Perovskite cell edge cleaning

- Laser texturing: Multimode lasers are also widely used in material surface texturing to enhance surface adhesion. According to different roughness requirements, selecting single pulse energy (such as 5, 15 or 50 mJ ) can achieve a variety of surface treatment effects, suitable for coating, adhesive processing and other applications.

Figure 9:Laser texturing

Summarize

Single-mode lasers have the characteristics of high beam quality and strong cleaning ability, while multi-mode lasers have the characteristics of flat-top beam, high energy, long focal depth, little damage to the substrate or even no damage.

Single-mode lasers are suitable for high-precision cleaning tasks, especially for removing rust and cleaning complex small parts , and can provide more accurate and powerful cleaning effects . Multi-mode lasers are suitable for uniformly treating large areas of contaminants, such as mold cleaning and solar cell manufacturing , with little or no damage to the substrate.