Laser marking anodized aluminum has become an essential process in industries that demand high-quality, permanent, and readable markings on metal surfaces. While conventional engraving removes the anodized coating to expose the natural aluminum beneath, achieving deep black marks requires precise control of laser parameters. In this study, we conducted systematic experiments to evaluate how Q-frequency, pulse width, marking speed, and fill density influence the quality, contrast, and uniformity of black laser marks on anodized aluminum.

Experimental Setup and Methodology

The experiments were conducted using a 60W MOPA fiber laser with f160/f245 lenses. Anodized aluminum samples were cleaned with isopropyl alcohol to remove dust and fingerprints, then fixed securely on a flat fixture tray to prevent movement during marking. Vector designs were prepared in DXF format for consistent, repeatable paths.

The four key parameters were varied individually while keeping others constant, allowing us to isolate their effects on mark quality.

The Influence of Pulse Frequency (Q-Frequency)

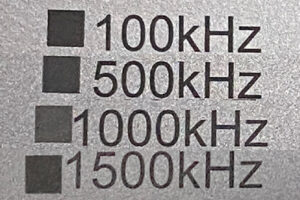

Through testing, mid-range frequencies of 200–800 kHz achieved the darkest and most uniform black marks without damaging the surface. This demonstrates the importance of balancing pulse energy and repetition rate for optimal results.

Figure 1: Comparison of Q-Frequency results

The Influence of Pulse Width

Pulse width (ns) is the duration of each laser pulse. Wide pulses (100–200 ns) release energy over a longer period, often damaging the anodized layer and causing whitish or irregular marks. Narrow pulses (2–4 ns) concentrate energy into brief bursts, producing fine, deep black marks with minimal surface disruption.

Narrow pulse widths are essential for high-quality black marking, ensuring both visual contrast and preservation of the anodized aluminum surface.

The Influence of Marking Speed

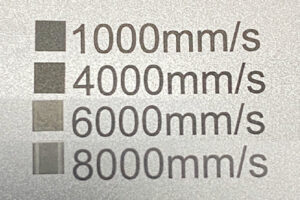

Marking speed affects how much energy the laser deposits per unit area. Slower speeds (1000–3000 mm/s) allow more dwell time, resulting in dense, deep, and uniform black marks. Medium speeds (4000–5000 mm/s) still yield dark marks with slightly reduced depth. High speeds (6000–8000 mm/s) produce grayish, uneven markings due to insufficient energy per spot.

Thus, careful speed selection is crucial to achieving consistent black marks across the entire surface.

Figure 2: Comparison of Marking Speed results

The Influence of Fill Density

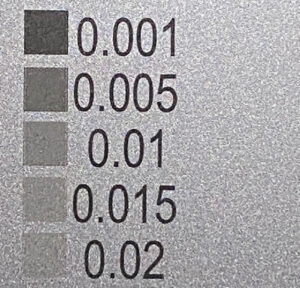

Fill density defines the spacing between laser scan lines. Sparse fill (0.001 mm) leaves gaps, causing lighter, inconsistent marks. Denser fills (0.01–0.02 mm) create darker, more uniform black markings.

Optimal fill density balances marking time and quality. For most applications, a density range of 0.001–0.005 mm provides deep black results without significantly increasing processing time.

Figure 3: Comparison of Fill Density results

Recommended Parameter Ranges

Based on experimental observations, the following parameters are recommended for laser marking anodized aluminum to achieve optimal black marks:

Table 1 Parameter summary table for black marking on anodized aluminum

| Parameter | Recommended Range | Notes |

| Q-Frequency | 40–60 kHz | Mid-range gives uniform black |

| Pulse Width | 2–4 ns | Narrow pulses for deep, clean marks |

| Marking Speed | 1000–5000 mm/s | Slower speeds ensure uniform black |

| Fill Density | 0.001–0.005 mm | Dense enough for consistent darkness |

| Laser Type | 60W MOPA Fiber | Stable power and wavelength control |

| Lens | f160 / f245 | High precision focusing |

Conclusion

Through systematic experimentation, we have demonstrated how Q-frequency, pulse width, marking speed, and fill density influence black laser marking on anodized aluminum. By carefully selecting mid-range frequencies, narrow pulse widths, slower to medium speeds, and optimal fill density, manufacturers can achieve high-contrast, uniform, and durable marks suitable for industrial and consumer applications.

Using these optimized parameters ensures repeatable quality, minimal surface damage, and efficiency in production.