LC1410D-V-QCS Rust removal laser gun cleaner with QCS Interface

- 10mm Aperture, Double Axes Vertical Light

- Power Range:≤200W Pulsed Laser

Rust removal laser gun cleaner with QCS Interface

- 10mm Aperture, Double Axes Vertical Light

- Power Range:≤200W Pulsed Laser

What role dose the rust removal laser gun cleaner play in laser cleaning machine?

The rust removal laser gun cleaner is a key component of a laser cleaning machine and plays a central role in the process of removing rust and other contaminants from surfaces. Here’s an overview of the role it plays in the cleaning machine:

Generation of Laser Beam:

The rust removal laser gun cleaner is responsible for generating the high-intensity laser beam used in the cleaning process. Typically, fiber lasers are employed for their efficiency, reliability, and suitability for industrial applications.

Emission of Laser Pulses:

The laser gun cleaner emits laser pulses with controlled parameters, including power, duration, and frequency. These parameters are adjusted based on the specific requirements of the cleaning task and the type of material being treated.

Targeting and Precision:

The design of the laser gun cleaner allows for precise targeting of the contaminated areas. This precision is crucial for effective rust removal while minimizing the impact on the underlying material.

Focused Energy Delivery:

The laser gun cleaner focuses the laser energy onto the rusted surface. As the laser beam interacts with the rust, it heats the material, causing it to vaporize or be blown away. This process results in the removal of rust and other unwanted substances.

Adjustable Settings:

Operators can adjust various settings on the rust removal laser gun cleaner, such as power levels and pulse durations. This flexibility allows customization of the cleaning process for different materials and surface conditions.

Integration with Automation:

In advanced laser cleaning machines, the rust removal laser gun cleaner is often integrated with automation systems. This integration may involve robotic arms or scanners to control the movement of the laser beam, ensuring uniform cleaning across large surfaces.

Safety Features:

The laser gun cleaner is equipped with safety features to protect operators and ensure safe operation. These features may include enclosures, interlocks, and emission monitoring to prevent accidental exposure to laser radiation.

Maintenance and Calibration:

Regular maintenance and calibration of the rust removal laser gun cleaner are essential to keep the entire laser cleaning machine operating at peak efficiency. This includes checking the alignment of optics and verifying the accuracy of laser parameters.

In summary, the rust removal laser gun cleaner is the component responsible for generating and delivering the laser energy needed for efficient and precise rust removal in laser cleaning machines. Its design and functionality are critical to the overall performance of the cleaning system in industrial applications.

Rust removal laser gun cleaner Technical Parameters

| General Parameters | |

| Laser Adaptation Range | QCS Laser |

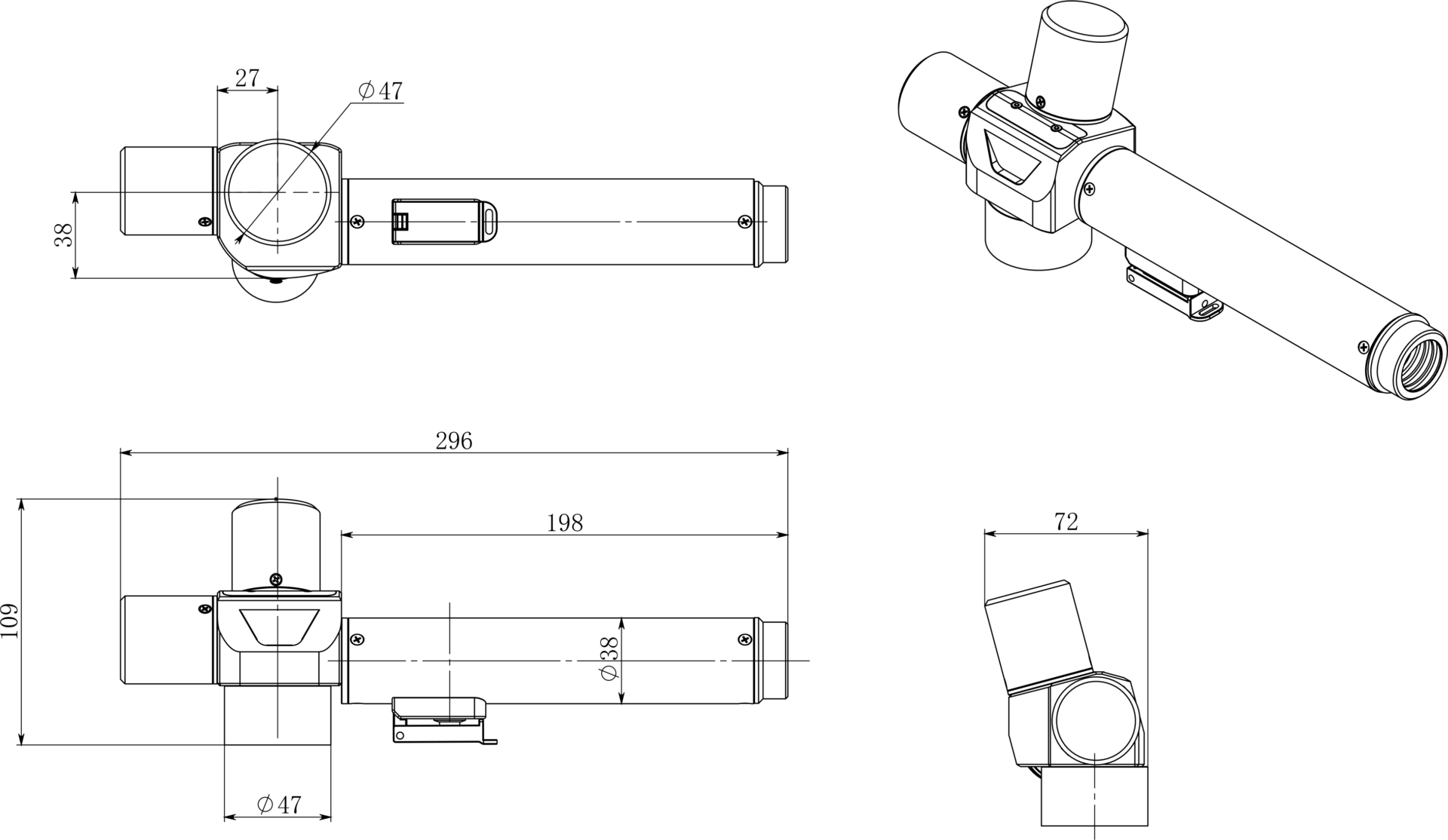

| Galvanometer Dimension | 296mm×76.3mm×108.7mm |

| Galvanometer Weight | 0.7±0.1Kg |

| Cable Length/m | 5(Length is customizable) |

| Cleaning Field | 100*20mm (or customized) |

| Mechanical Scan Angle | ±11° |

| Precision and error | |

| Linearity | 99.9% |

| Repeatability | 8μRad. |

| Scale Drift | <40PPM/℃ |

| Zero Drift | <15μRad./℃ |

| Long-term Drift Over 8 Hours | <0.5mRad. |

Rust removal laser gun cleaner configuration List

| Product Name | Specification | Qty/set |

| Power supply | ±15V, 2A | 1 |

| Control card | V1.2/1.3 | 1 |

| Touch screen | 3.5 inch/7 inches (optional) | 1 |

| F-theta lens | F=254mm | 1 |

| Hand Piece | LC1410D-V-QCS | 1 |

| Laser connection cable | DB25 | 1 |