Previous

Next

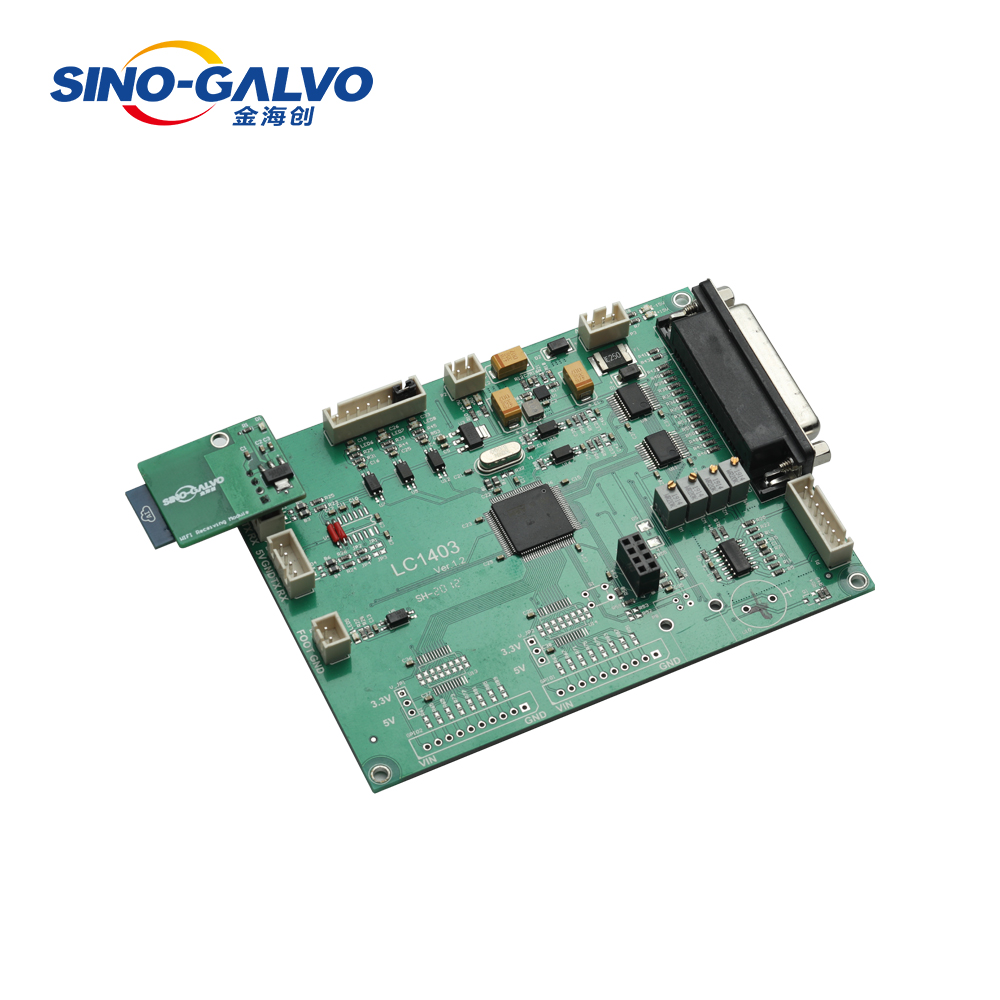

Sino Galvo Control Card with software

- Adopting high-performance control chip, with faster speed to control system

- Support 4-axis stepper motor and servo motor (CSG9210 V4 and CSG9310), with hardware-level left and right limit and origin detection functions

- Single control board can synchronously control 5 sets of galvanometers

- Support PWM control

Previous

Next

Sino Galvo Control Card with software

- Adopting high-performance control chip, with faster speed to control system

- Support 4-axis stepper motor and servo motor (CSG9210 V4 and CSG9310), with hardware-level left and right limit and origin detection functions

- Single control board can synchronously control 5 sets of galvanometers

- Support PWM control

Product Features

Product Features

Control Card Comparison

| CS9210 V4 | CSG9210 V5S | CSG9310 | |

| Software | JHC Laser mark | JHC Laser mark | JHC Laser mark |

| Connection method | USB | USB | USB and Network port |

| Camera | √ | √ | √ |

| Flying marking | × | × | √ |

| Multiple heads | √ | √ | √ |

| Secondary development | √ | √ | √ |

| Two-axis linkage | √ | √ | √ |

| Offline marking | × | × | √ |

| 2.5D stepper, large format, deep engraving | √ | √ | × |

| 3D Curved | × | × | × |

| Expansion axis and galvanometer linkage scheme | √ | √ | √ |

| Uniform marking | √ | √ | √ |

| TCP/IP remote control | × | × | √ |

| Galvo high-precision correction | High-precision proportional correction | ||

| Galvo power control linear change | √ | √ | √ |

| Laser source | Supports various mainstream laser types | ||

| Linear variation of laser power control | √ | √ | √ |

| software kernel | 64/32 | 64/32 | 64/32 |

| Laser source | It supports CO2, YAG, FIBER, SPI, etc. The current, pulse frequency, duty cycle and other parameters can be adjusted by software according to different laser parameters. The laser status can be displayed in real-time. | ||

| Red light display | Support, red light is an indicator light | ||

| Password control | Supported to prevent parameters from being arbitrarily modified | ||

| IO control | Added port control functionality to easily automate your machine. | ||

| Galvo correction | Distortion correction, high-precision proportional correction, multi-point correction | ||

| Filling | Background padding, ring padding, arbitrary angle padding, cross padding, margins, borders, and spacing are adjustable. | ||

| Multi-layer filling is supported, and parameters can be set independently for each layer. | |||

| Processing function | Large format dynamic focus, projector positioning function, multiple extension axes, estimated processing time, ultra-fast dot-like 2D barcode marking, fill even function, power and speed fade in and out, circular and sinusoidal jitter Function, material parameter assistant function. | ||

| Edit function | Multi-layer, 3D curve marking, slice function, dynamic filling, 3D curve projection, surface wrapping, bitmap | ||

| Convert to Emboss, Arbitrary Curve Text, Arbitrary Graphics Draw/Edit, Break/Group, Group/Dissolve, Cancel/Restore, Weld, Trim, Cross, Align, Automatic Curve Connection, etc. | |||

| Text input function | Support True Type font, single line font (JSF), dot matrix font (DMF), SHX, support user-built font library. | ||

| Barcode and QR code | Code39、EAN、PDF417、DATAMATRIX、QR and etc. | ||

| Vector file | PLT/DXF/AI | ||

| Bitmap file | BMP/JPG/JPEG/GIF/TGA/PNG | ||

| Variable text | Fixed text, date, time, keyboard input, jump number, list file, dynamic file, support EXCEL table, TXT file, support serial communication, network communication. | ||

| Multilingual support | Built-in Chinese, English, can be switched arbitrarily | ||

| Offline layer | Supports switching and processing of multiple layers | ||

| Online circular interpolation command | Support, for high precision small circle machining | ||