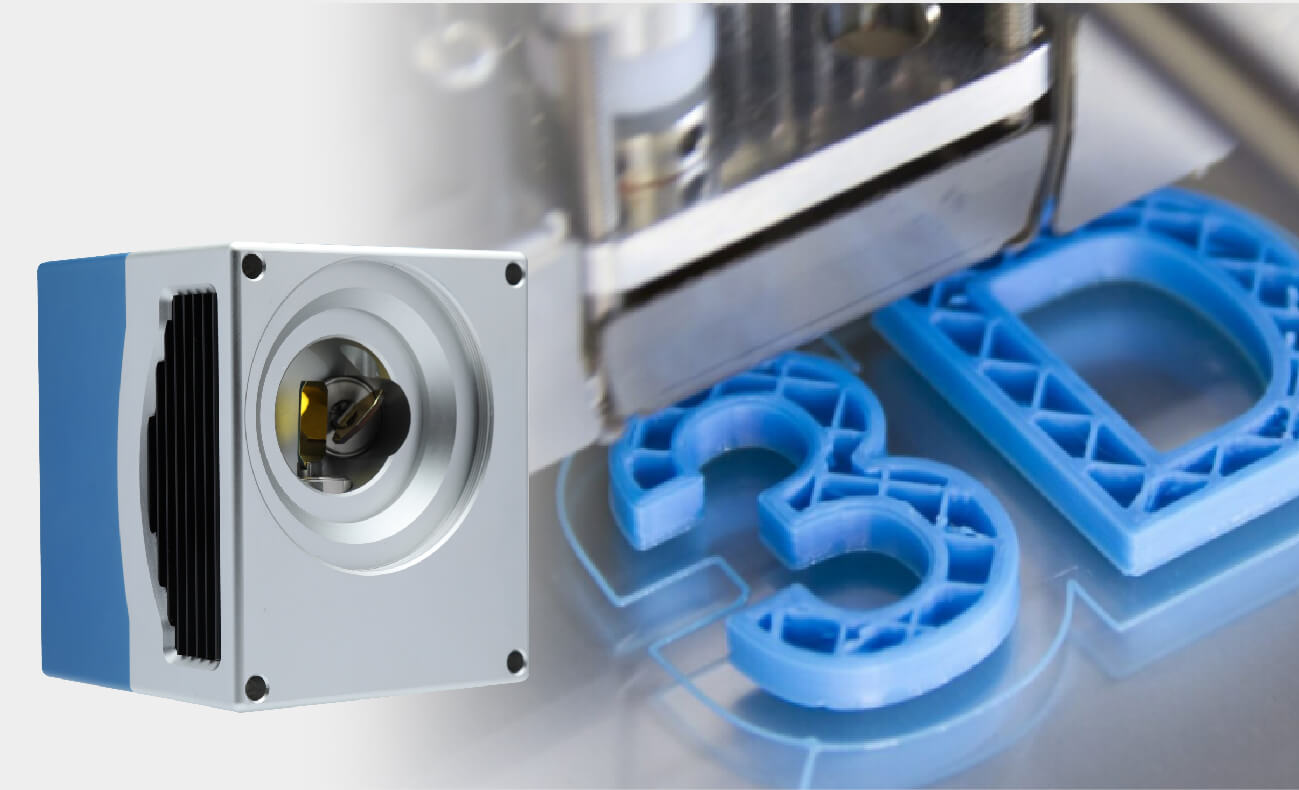

In the rapidly evolving field of additive manufacturing, stainless steel 3D printing has emerged as a cornerstone for industries ranging from aerospace to medical devices. However, achieving high precision, speed, and repeatability in metal 3D printing hinges on one critical component: laser scanning galvanometer systems. As a professional manufacturer specializing in galvanometer scanner R&D, we understand the technical nuances that define success in stainless steel 3D printing. In this article, we’ll explore how selecting the right galvanometer scanners can dramatically improve efficiency while highlighting our expertise in delivering cutting-edge solutions backed by robust technical support.

Why Galvanometer Scanners Matter in Stainless Steel 3D Printing

Stainless steel’s high melting point, thermal conductivity, and reflectivity pose unique challenges for laser-based 3D printing. A high-performance galvanometer scanner ensures precise laser beam positioning, enabling:

Faster Scanning Speeds: Reduced layer fabrication time through optimized acceleration and deceleration.

Superior Accuracy: Micron-level precision for complex geometries and fine details.

Thermal Stability: Consistent performance under prolonged high-power laser exposure.

For industries requiring dense, corrosion-resistant stainless steel parts, the right scanner minimizes defects like porosity and warping, directly impacting production ROI.

Key Considerations When Selecting a Galvanometer Scanner

To maximize efficiency in stainless steel 3D printing, focus on these technical criteria:

- Dynamic Performance and Scanning Speed

High-speed galvanometers with low inertia mirrors (e.g., aluminum or silicon carbide) ensure rapid directional changes without sacrificing accuracy. Look for scanners with ≥5 m/s scan speeds and acceleration rates exceeding 50,000 rad/s² to handle intricate stainless steel builds.

- Thermal Management Capabilities

Stainless steel printing demands prolonged laser exposure, generating significant heat. Opt for scanners with integrated cooling systems (e.g., water or thermoelectric cooling) to maintain mirror alignment and prevent thermal drift.

- Compatibility with High-Power Lasers

Ensure the scanner’s optical coatings (e.g., protected gold or dielectric) withstand 1,070 nm fiber lasers at power levels up to 1,000W. This minimizes energy loss and protects against laser-induced damage.

- Software Integration and Calibration

Advanced control software with real-time feedback loops compensates for positional errors. Features like Precision Closed-Loop Control and Field Calibration adapt to varying stainless steel powder bed conditions.

Our Expertise: Engineering Galvanometer Scanners for Stainless Steel 3D Printing

As a leader in galvanometer technology, our solutions are tailored to meet the rigorous demands of industrial-grade stainless steel 3D printing:

Proprietary Mirror Coatings: Optimized for high reflectivity (≥98%) at 1,064 nm, reducing laser power waste.

Customizable Scan Fields: From 100×100 mm to 500×500 mm, adaptable to any printer architecture.

24/7 Technical Support: Our team provides rapid troubleshooting, calibration services, and firmware updates.

The Role of After-Sales Support in Sustaining Efficiency

Investing in advanced galvanometer technology is only half the battle. To ensure long-term performance, our comprehensive after-sales service system includes:

Onsite Training: Optimize scanner settings for stainless steel parameters.

Predictive Maintenance: Remote monitoring tools preemptively flag alignment or cooling issues.

Spare Parts Availability: Minimize downtime with globally stocked components.

Conclusion

In stainless steel 3D printing, the choice of galvanometer scanners directly dictates productivity, part quality, and operational costs. By prioritizing speed, thermal resilience, and precision engineering, manufacturers can unlock new levels of efficiency.

As a trusted partner in galvanometer innovation, we combine 20+ years of R&D experience with a commitment to client success. Whether you’re prototyping or scaling production, our scanners are engineered to excel in the most demanding stainless steel applications.

Ready to optimize your 3D printing workflow? [Contact our team] to explore tailored galvanometer solutions backed by unmatched technical expertise.