What is F theta lens?

F theta lens is a specific type of lens commonly used in laser systems, particularly in laser marking, engraving, cutting, and scanning applications. The lens is designed so that the image height and scanning angle satisfy the relationship formula y=f*θ (θ is the deflection angle of the galvanometer), so the f-θ lens is also called a linear lens. When the lens is used in conjunction with a scanning mirror, the laser beam maintains a consistent spot size across the entire scanning area, resulting in uniformity of focus and precision in material processing applications.

How to choose an appropriate f theta lens?

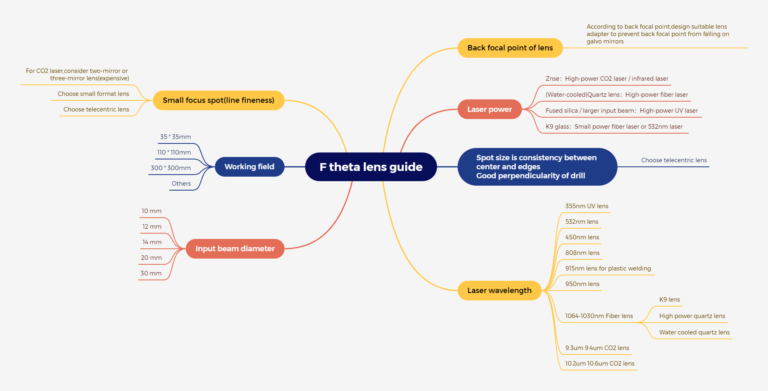

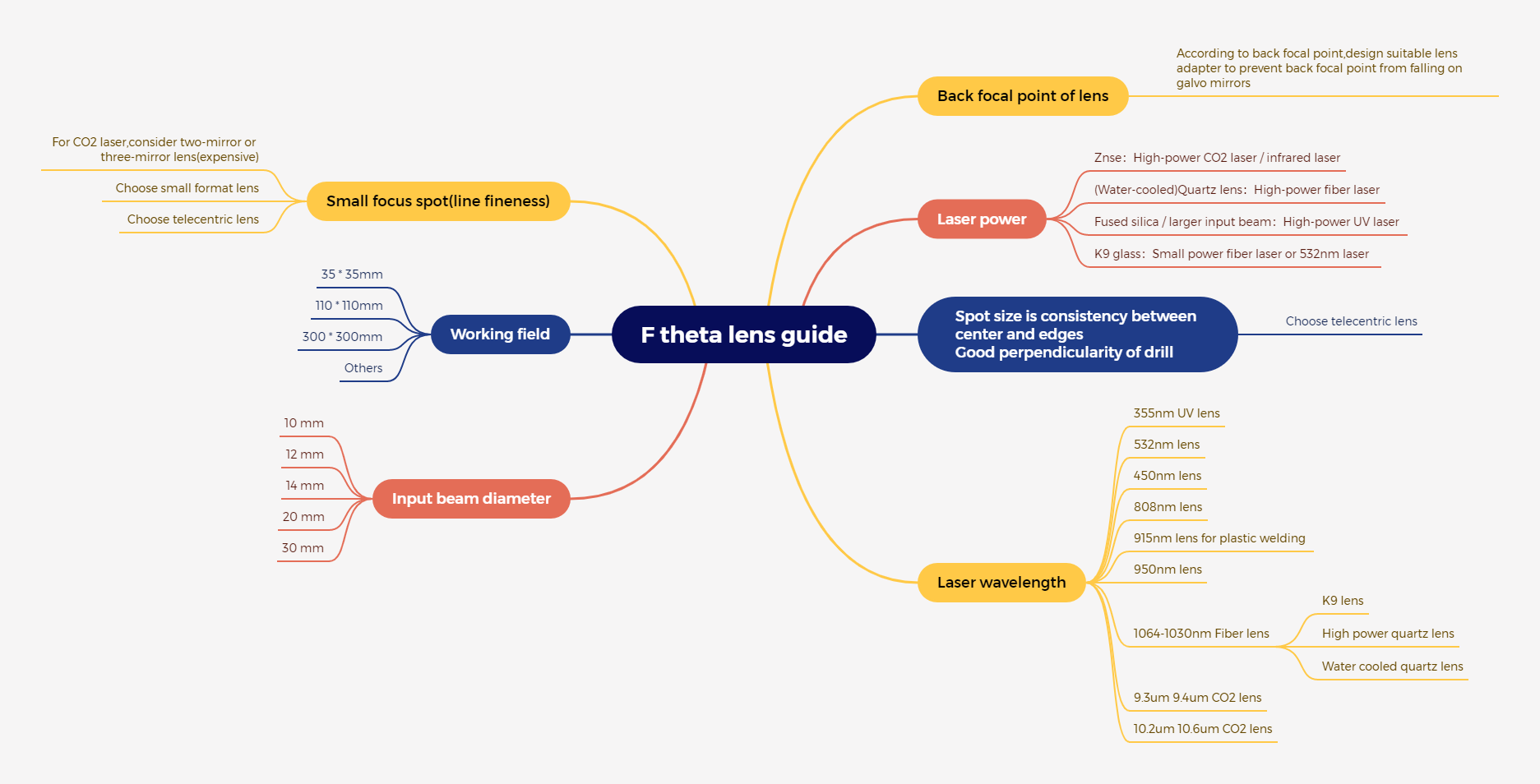

F theta lens Wavelength

The wavelength of the f theta lens is determined by the laser marking system. The fiber laser wavelength is 1064nm, CO2 laser wavelength is 10.6μm, green laser wavelength is 532nm, and ultraviolet laser wavelength is 355nm. We need to select the corresponding field mirror for the corresponding laser.

F theta lens Working field

The working field of the f theta lens is determined by the focal length. There is an empirical formula for focal length and working format: f=0.7×focal length. For example, the corresponding format of field lens with f=160mm is a square of 112 mm, and after correction, the field lens is rounded to 110mm×110mm.

F theta lens input beam diameter

The input beam size of the f theta lens should be the minimum of the following values: a. Laser beam diameter = laser beam size * beam expander; b. Galvanometer scanner aperture. If the beam diameter of the field lens is smaller than the laser beam size after the galvanometer scanner, then when working in full format, the center part is no problem, but the edge part will be weaker and the marking depth will be much shallower.

F theta lens Working distance

We need to consider the working distance when purchasing long focal length field lens. Because the adjustment height of the lifting column is limited, such as a 550mm lifting column, after installing the galvanometer and field mirror, when the column is adjusted to the highest point, the distance between the bottom edge of the field mirror and the marked object is around 400-440mm, but the focal length of the 300*300mm field lens is 430mm, the working distance is 480-490mm, so the height of the column is not enough. So, a 300*300 field lens needs to match 600mm columns. 500*500mm format field lens requires a 1000mm column. In addition, when considering the height of the column, we also need to consider the height of the marked object. If the height of the product itself is 100mm, then the height of the corresponding column should be added to the height of the product.

F theta lens Spot size

If there are requirements for the spot size, we could refer to the formula: Spot size=1.83×λ×f/D to choose the appropriate field lens focal length and beam diameter. The larger the scanning range, the larger the spot size will be, and the spot will not be fine enough. The laser power density will drop very quickly (the power density is inversely proportional to the square of the spot diameter), which is not conducive to processing. Therefore, it is recommended to select the most suitable field lens according to different processing areas or to reserve several field lenses with different scanning ranges.

F theta lens Thread

Generally, the installation thread of field lenses is M85*1, but the threads of galvanometer scanners are M79*1, M55*1, M39*1, etc. Therefore, when purchasing a field lens, you could choose one that is compatible with the galvanometer scanner or purchase a field lens adapter.

Curved or stepped object

Curved or stepped products require a certain focal depth of the field lens, that is, the corresponding focal length must be longer. You can click here to get the focus spot and depth of focus.

F theta lens focused spot power density

For example, we use 20W laser with 110*110mm f theta lens. If the working format is increased to 500*500mm, how to choose the laser power to achieve the same marking depth as before? (The thickening of the focal spot is not considered here)

We can refer to the following formula

A laser power/A machine minimum spot size*A machine power percentage=B laser power/B machine minimum spot size*B machine power percentage

Eg: 20W/31μm*100%=Power? /110μm*100%; Power=71W

In addition to those mentioned in the article, some other parameters may also need to be considered, such as M1 and M2 values (the distance between the galvanometer lens and the field lens), scanning angle θ, lens size, back reflection point, etc.Moreover, if the fineness and working field cannot be achieved together, you can 1) choose 3D dynamic galvo scanner; 2) choose small-format f theta lens for XY platform segmentation and marking; 3) choose telecentric f theta lens; 4) choose ultraviolet or deep ultraviolet laser machine.