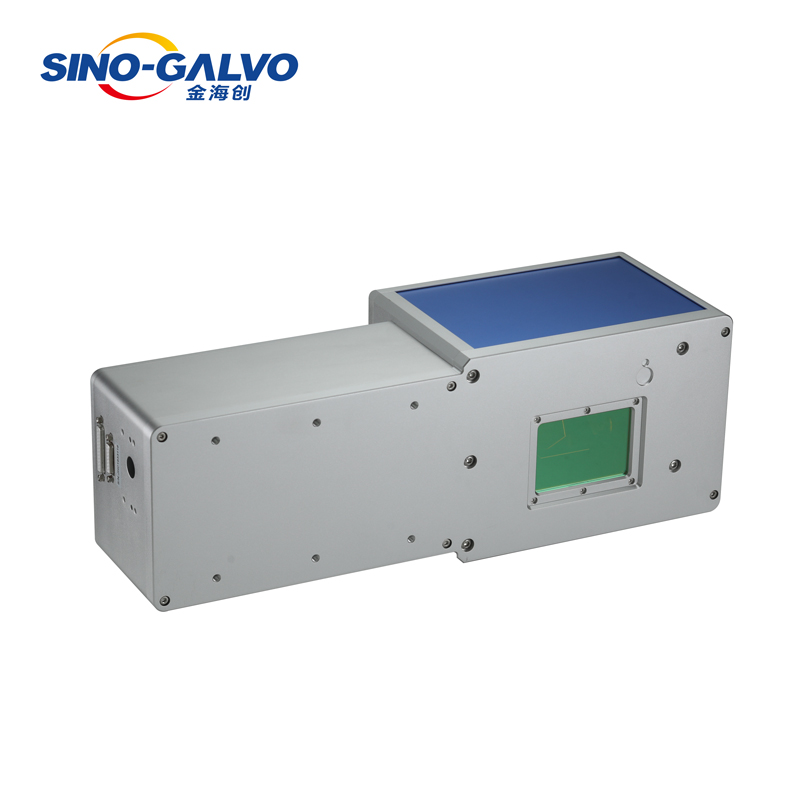

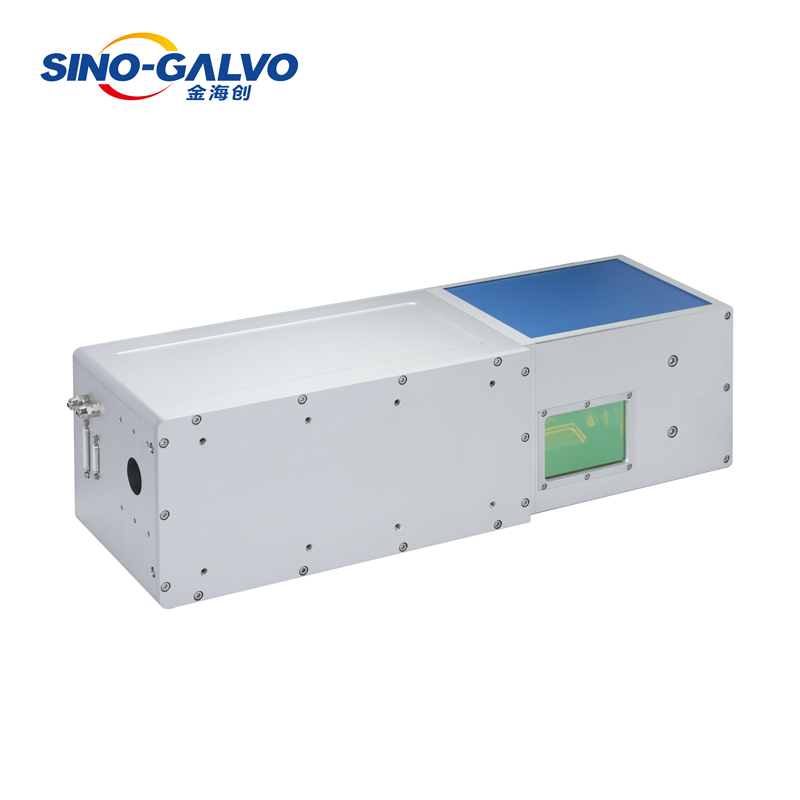

The galvanometer scanner is also called a laser scanner, and its design idea follows the design method of the ammeter. The principle is to input a position signal, and the galvanometer will swing a certain angle according to the conversion ratio of a certain voltage and an angle. In the galvanometer scanning system, the waveform of the optical scanning is a vector scanning, and the scanning speed of the system determines the stability of the laser pattern. The main advantages of galvo scanner is high speed and high precision, which are widely used in laser marking, life science, digital imaging (medical imaging and microscopy, optical coherence tomography).

What is a galvo components

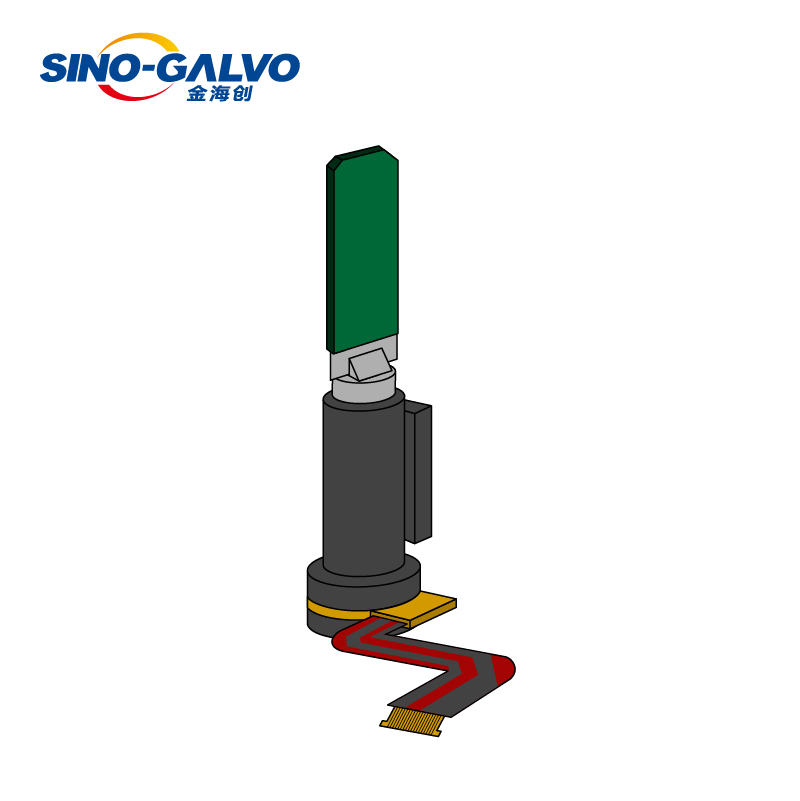

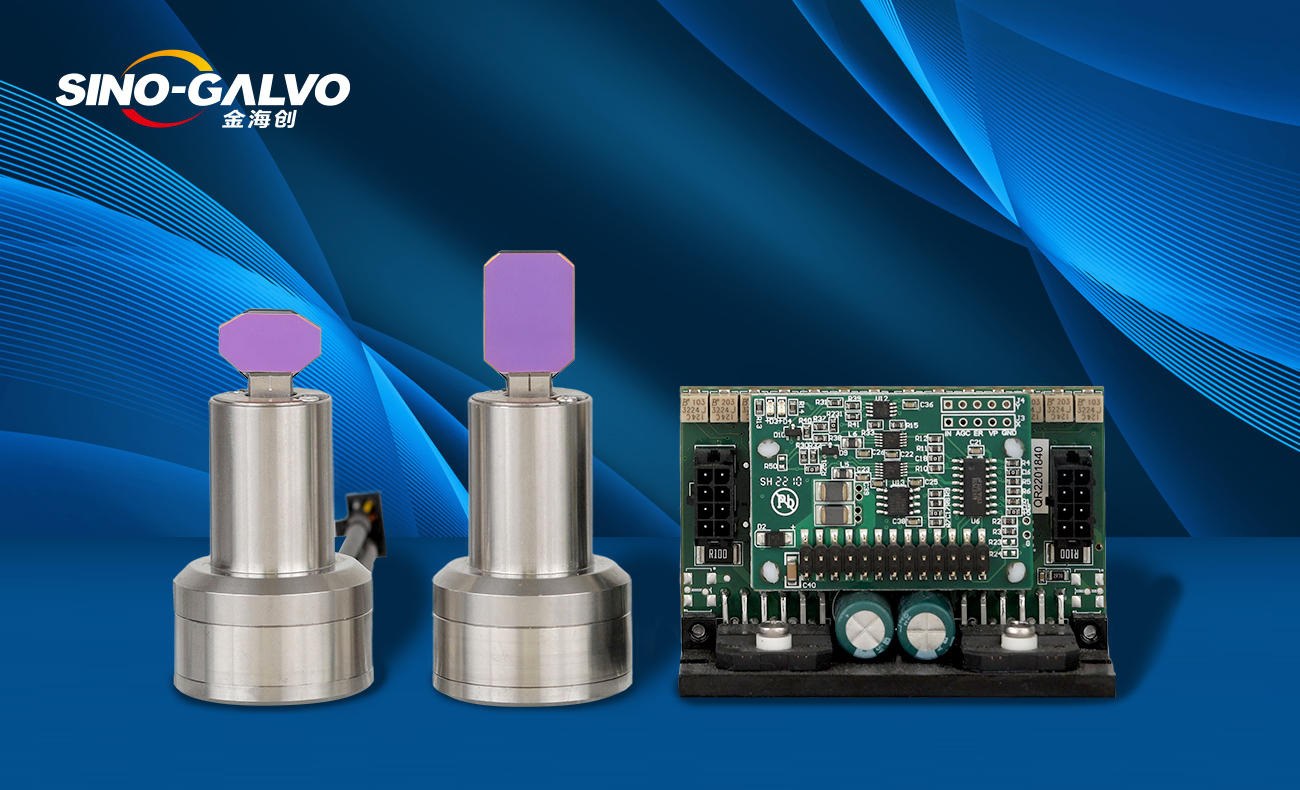

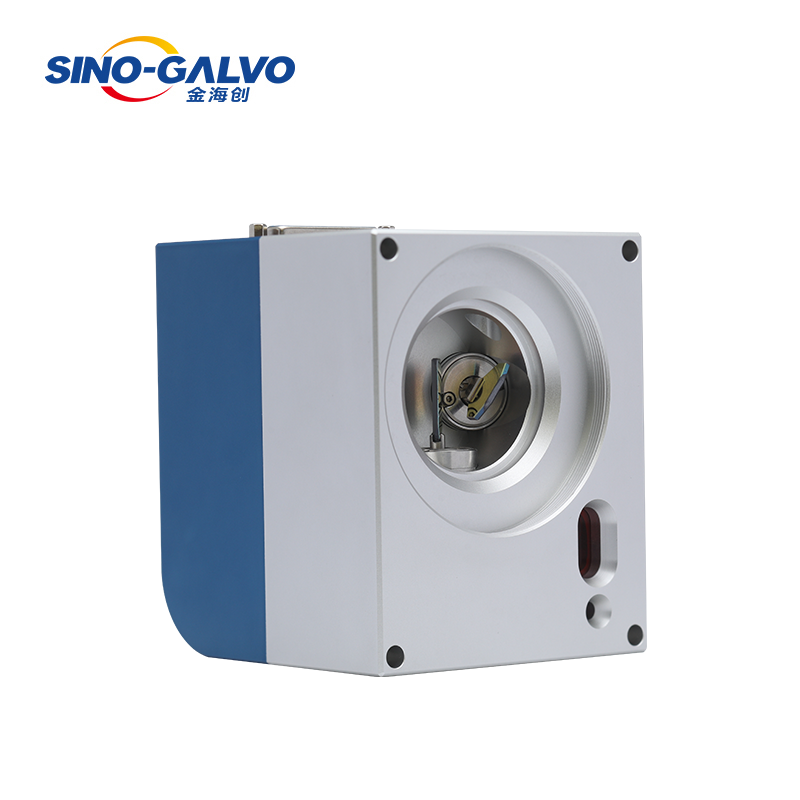

- Mirrors: Usually, there are two mirrors: one controlling the X-axis (horizontal) and the other controlling the Y-axis (vertical). The laser beam is reflected off these mirrors, altering its direction.

- Servo Motors or Electromagnetic Actuators: These drive the rotation of the mirrors. The servo motors precisely control the rotation angle of the mirrors through electrical signals, thereby adjusting the direction of the laser beam.

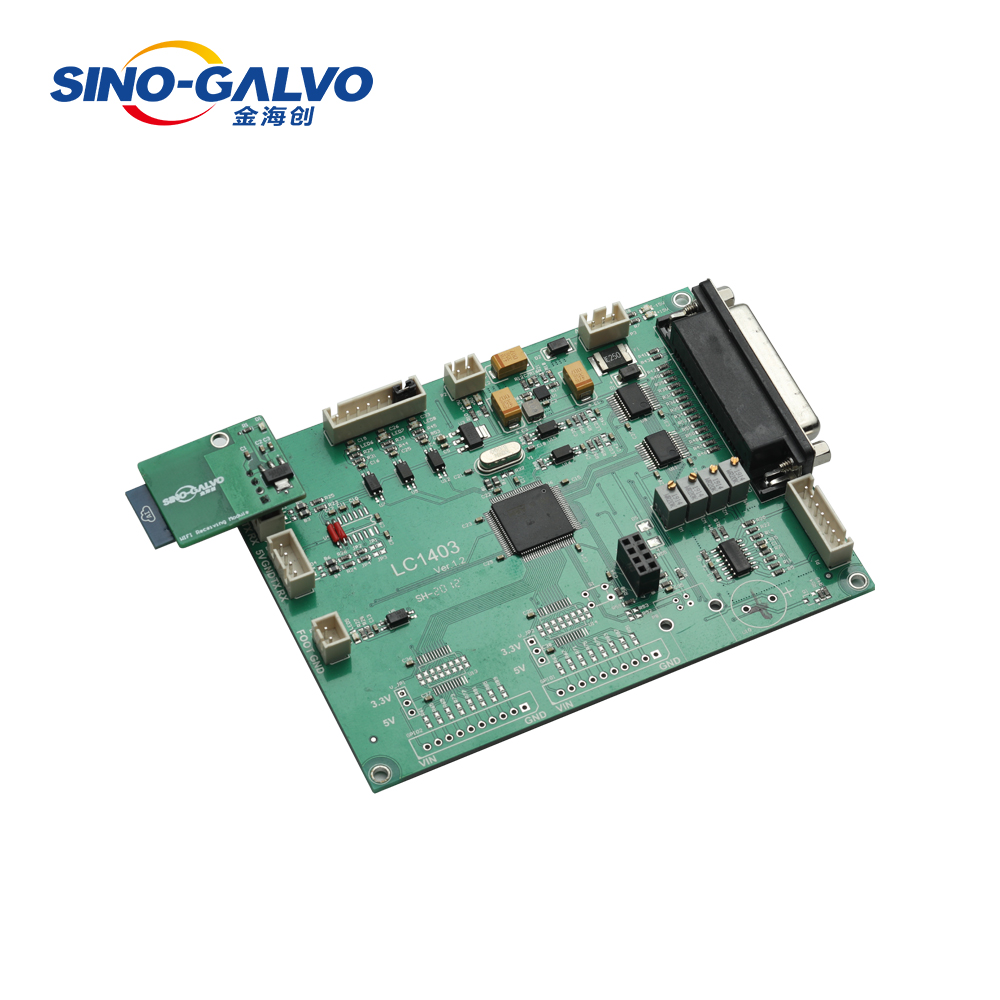

- Control System: It inputs electrical signals or pre-programmed commands to control the rotation angle and speed of the mirrors. A closed-loop control system is typically used in conjunction with position sensors to provide real-time feedback, ensuring the accuracy of mirror movements.

- Position Sensors: These detect the rotation angle of the mirrors and provide feedback signals to the control system, ensuring that the laser beam is positioned correctly.

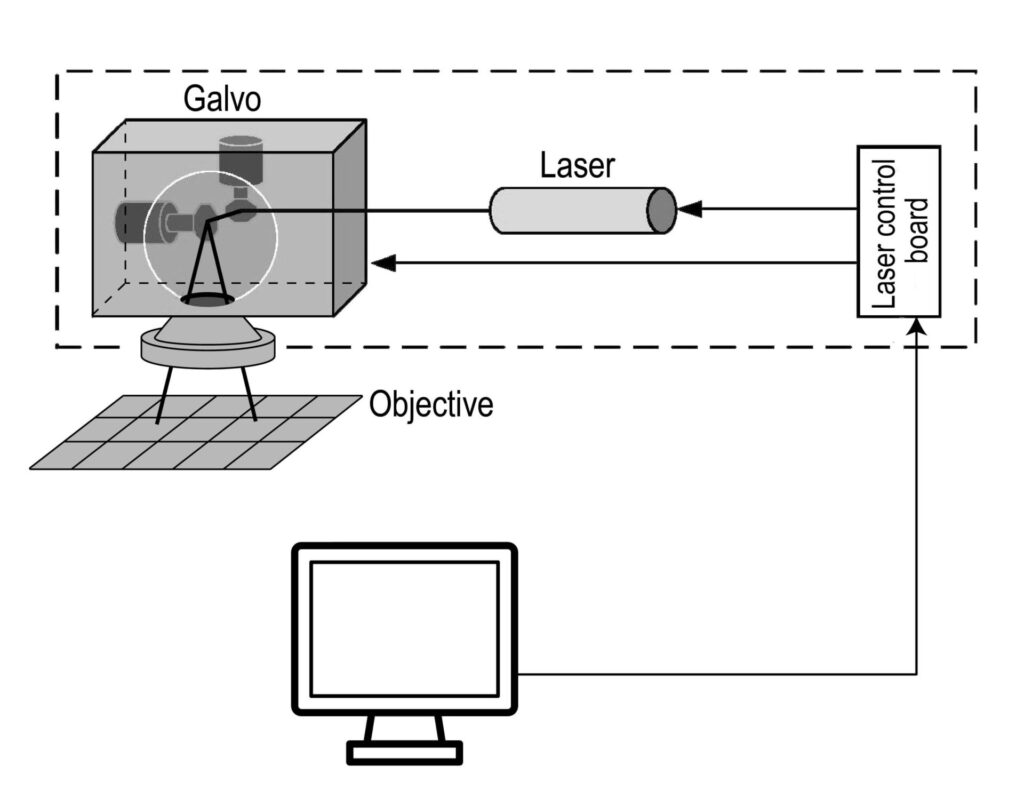

Galvanometer scanner how it works

The working principle of a galvanometer scanner involves optical, mechanical, and control aspects. Firstly, the scanner usually contains mirrors that can be rotated or tilted through mechanical devices. Secondly, there is typically a light source above the scanner, such as a laser, which emits a beam of light that is directed at the scanner’s mirrors. Lastly, a light detector is usually positioned above the scanner to receive the reflected light signals. When the light beam hits the surface of the scanner, based on the laws of refraction and reflection, the light will be refracted or reflected. The movable mirrors on the scanner can be tilted through mechanical devices to adjust their angle, changing the direction of the light. When the mirror tilts, the light beam is deflected, and its direction and angle are determined by the scanner’s rotation angle. By controlling the mechanical components of the scanner, the direction and path of the light beam can be altered.

For example, when the scanner rotates at a certain speed and frequency, the light beam can scan across an area. Once the light beam hits a target object, it is reflected back. The light detector on the scanner can receive these reflected signals and measure parameters such as the intensity and time delay of the light.

Operating Mechanism of Galvo

The scanner operates using a closed-loop negative feedback control system. The voltage control signal is fed into the driver board, which generates current to drive the motor. As the motor oscillates to different positions, the optical sensor generates a position signal (voltage signal). The feedback compares this position signal with the input voltage, ensuring that the motor’s oscillation position matches the input signal. With precise angle control, the laser scanner can complete complex laser scanning patterns in a short time.

Advantages of Galvanometer Systems

- High Speed: Galvo systems can move the laser beam at extremely high speeds, performing thousands of beam positioning actions per second. This is particularly useful in applications requiring fast scanning, such as laser marking, engraving, and 3D printing.

- High Precision: The accuracy of Galvo systems is extremely high, often reaching micrometer or nanometer levels. This level of precision allows the system to produce detailed and complex designs, making it ideal for precision industrial manufacturing and microfabrication.

- Flexibility: Galvo scanners can easily adjust the beam direction, allowing coverage of larger areas without needing to move the workpiece. This flexibility enables the system to handle more complex geometries and dynamic processing needs, such as 3D laser printing and surface treatments.

- Reduced Mechanical Movement: Since the laser beam is directed by moving mirrors instead of moving the entire mechanical structure, Galvo systems reduce mechanical wear and extend the lifespan of the equipment. Moreover, fewer mechanical movements reduce error and enhance the quality of the processing.

- Multi-Axis Control: Some Galvo systems support multi-axis control, such as X, Y, and Z axes, allowing the beam to be more flexibly manipulated for three-dimensional processing. This is beneficial in more advanced industrial applications like 3D laser welding and cutting.

- Easy Integration: Galvo systems are compact and lightweight, making them easy to integrate into different types of equipment such as industrial robots, medical devices, and inspection instruments. Their modular design also allows them to be seamlessly combined with other automation systems, improving overall production efficiency.

- Low Power Consumption: Since the movement in Galvo systems is achieved through electromagnetic drives, they consume less power. Compared to traditional mechanical systems, Galvo scanners are more energy-efficient, making them more cost-effective, especially in large-scale production environments.

Applications of Galvanometer Scanner

- Laser Ranging (e.g.in radar distance measurement): When the laser beam hits a target object, the reflected light signal is affected by the scanner’s tilt angle. By measuring the difference between the incident and reflection angles, the distance between the object and the scanner can be calculated.

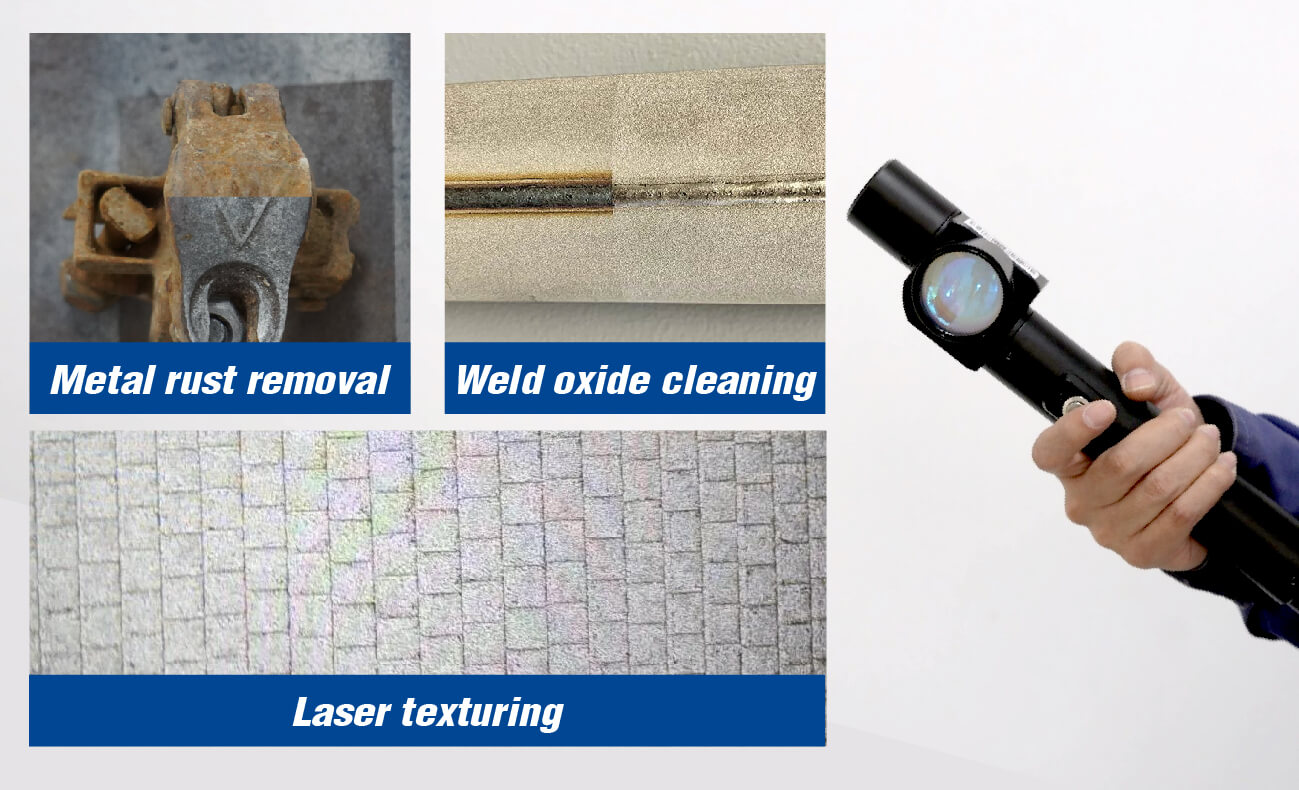

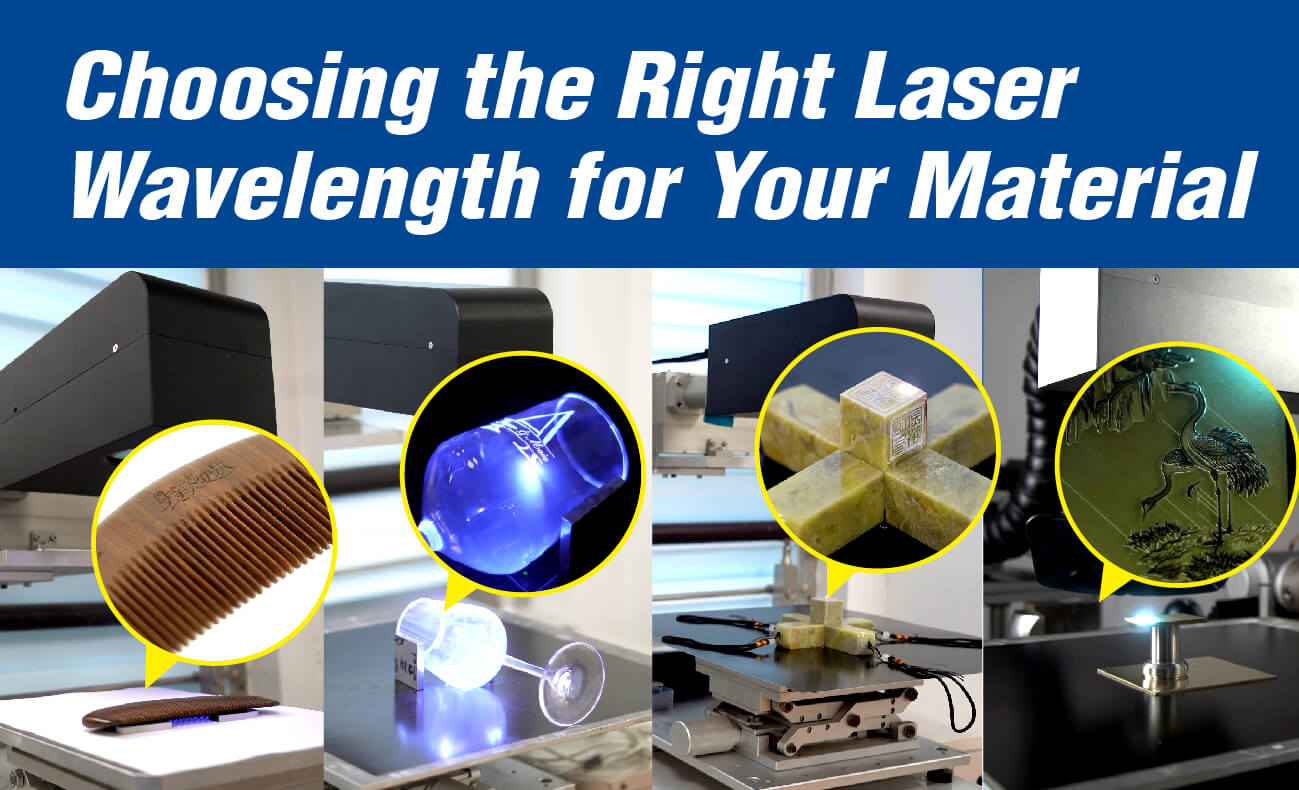

- Laser Systems: Galvos are used to control mirrors that redirect the laser beam across the work surface. By adjusting the angle of the mirrors with high precision, Galvos enable the laser to trace intricate patterns or perform detailed engraving, cutting and welding.

- 3D Printing: Scanners can guide the laser beam quickly and accurately to complete complex 3D structure printing, used in technologies like selective laser sintering (SLS) and selective laser melting (SLM), thus improving printing precision and efficiency.

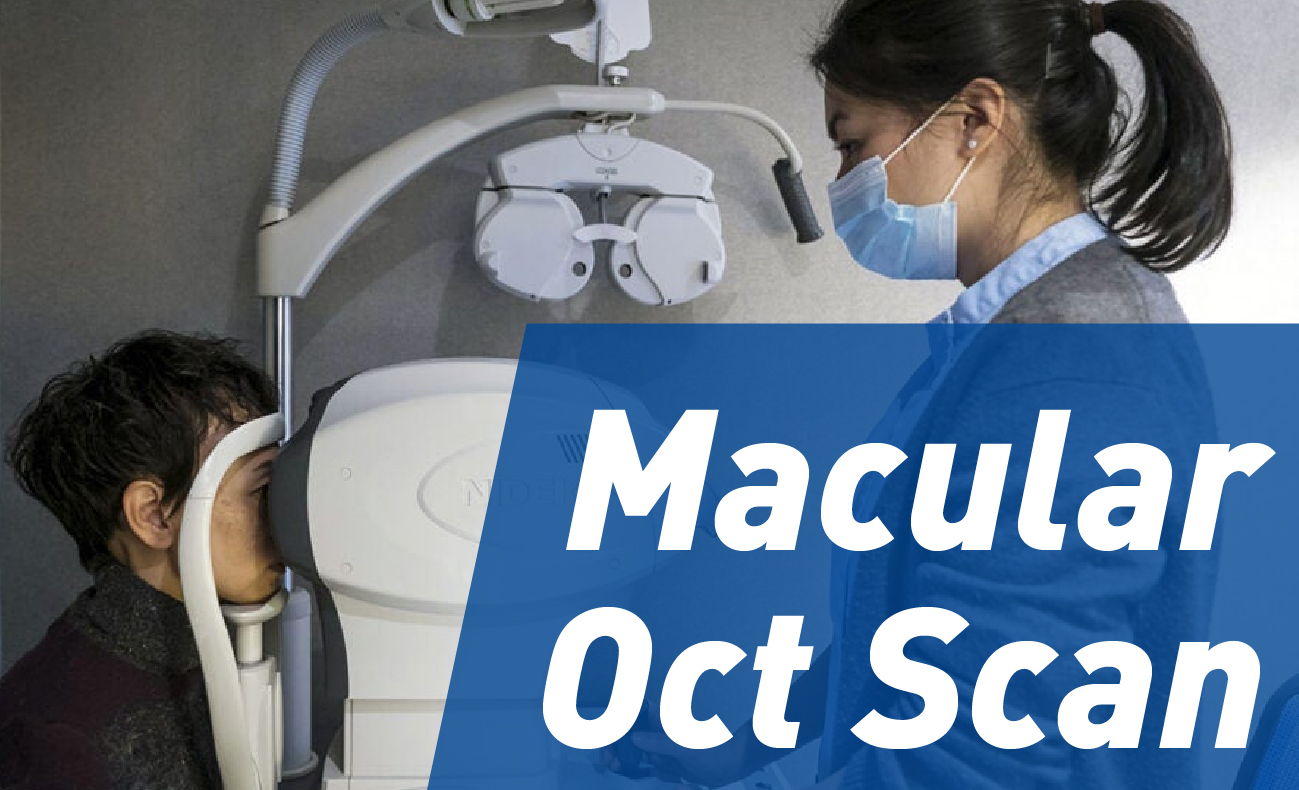

- Medical Applications: Scanner technology can achieve micron-level laser control, guiding the laser beam for precise treatments, such as in eye surgeries or skin treatments (e.g., laser mole removal, scar treatments).

- Laser Communication: Scanners can quickly and precisely adjust the direction of laser beams, ensuring stable and efficient data transmission. This is useful in space communication, satellite communication, and long-distance data transmission using laser beams.

In summary, Galvo scanners are essential for enabling the precise and rapid manipulation of laser beams in a wide array of industrial, medical, and scientific applications. Their speed and accuracy are what set them apart from other beam-steering technologies like mechanical stages or mirrors, which tend to be slower or less precise.